Fabric Hydrostatic Pressure Tester

A hydrostatic pressure and tester technology, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as increasing the overall volume of the tester, limited adjustment range, and test result errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

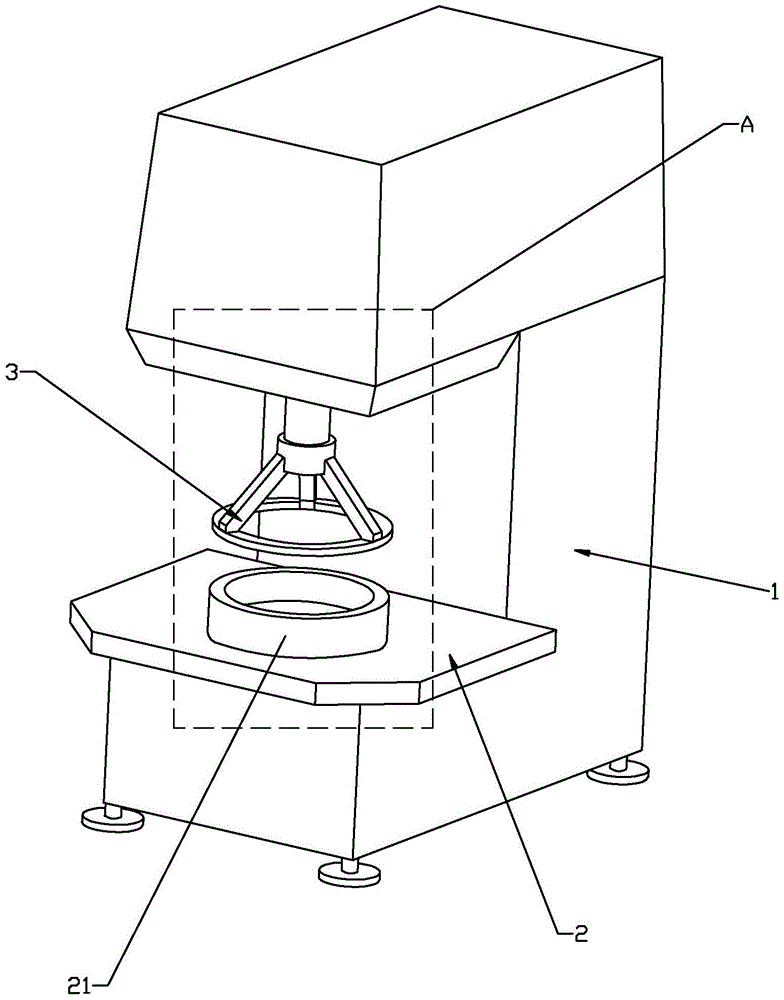

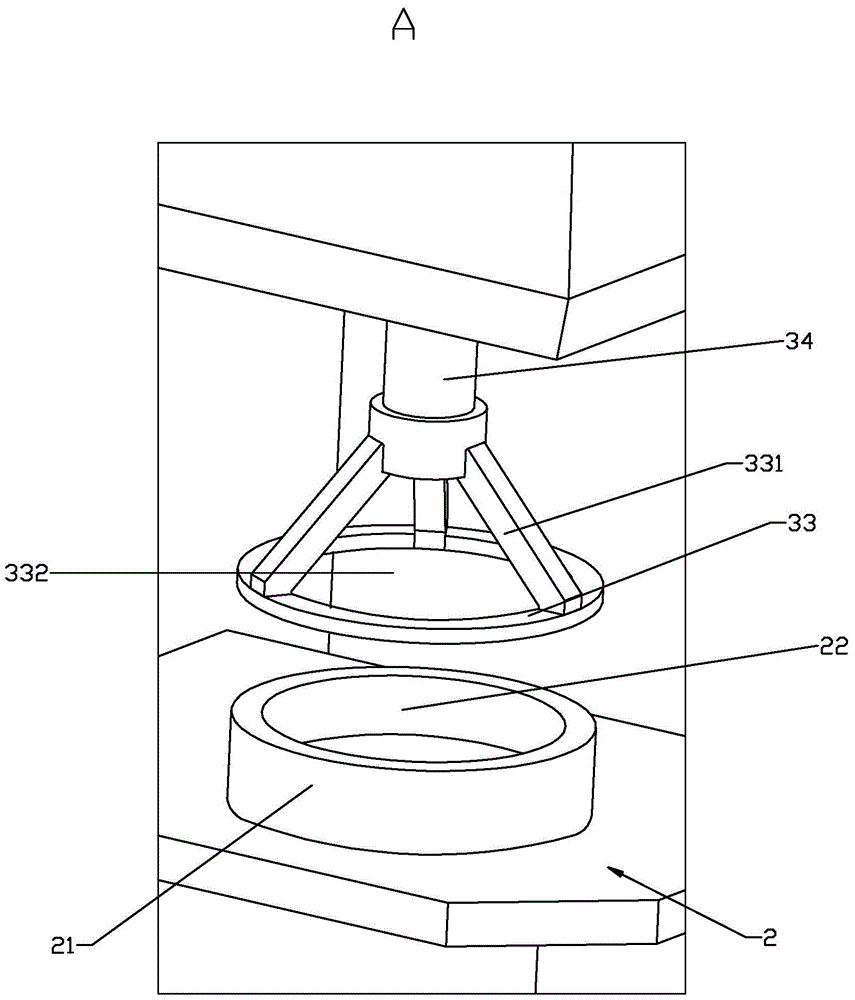

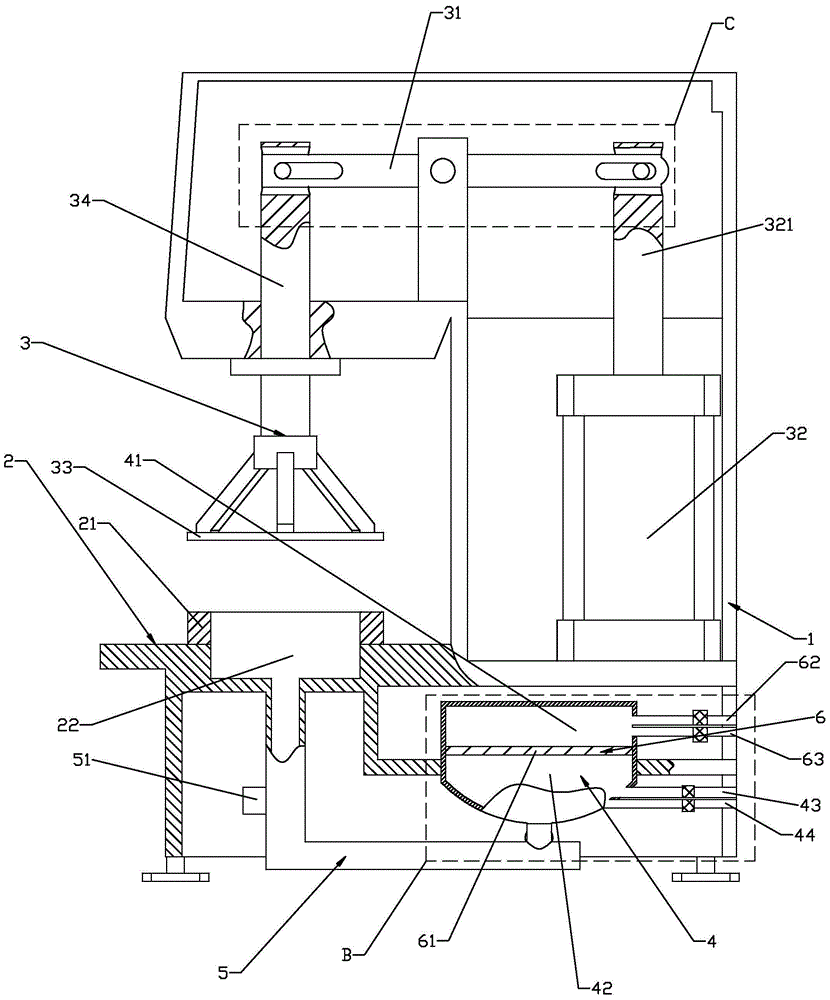

[0023] like figure 1 — Figure 5 As shown, the present invention discloses a fabric hydrostatic pressure tester, comprising a frame 1, a fabric mounting table 2 arranged on the frame 1, a fabric fixing mechanism 3, a water supply tank 4, a detection pipeline 5, and a fabric fixing mechanism 3 is located above the table top of the fabric installation platform 2, and the detection pipeline 5 is located below the table surface of the fabric installation platform 2 and communicates with the water supply tank 4. Squeeze or extract the water adjusting pressure mechanism 6, the water adjusting pressure mechanism 6 includes a piston plate 61 that slides in the water supply tank 4, and the piston plate 61 separates the space in the water supply tank 4 into an adjustment chamber 41 and a detection pipe 5 Unicom's water supply chamber 42, water regulating mechanism 6 also comprises the air inlet pipe 62 that regulates chamber 41 and gas source Unicom and the air outlet pipe 63 that comm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com