Particle six-sided inspection machine

A technology for inspecting machines and particles, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low precision, low inspection efficiency, low efficiency, etc., achieve high-precision product inspection, compact and reasonable structure, meet The effect of device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

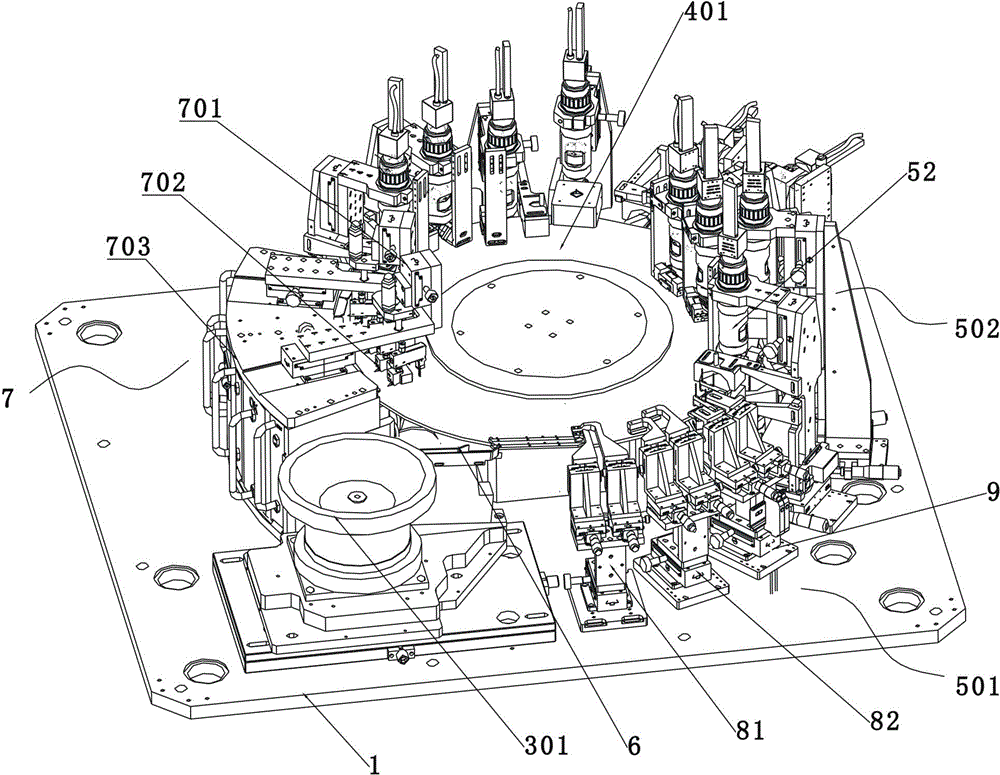

[0018] Below in conjunction with specific embodiment and accompanying drawing ( figure 1 , 2 ), further elaborating the essence of the present invention.

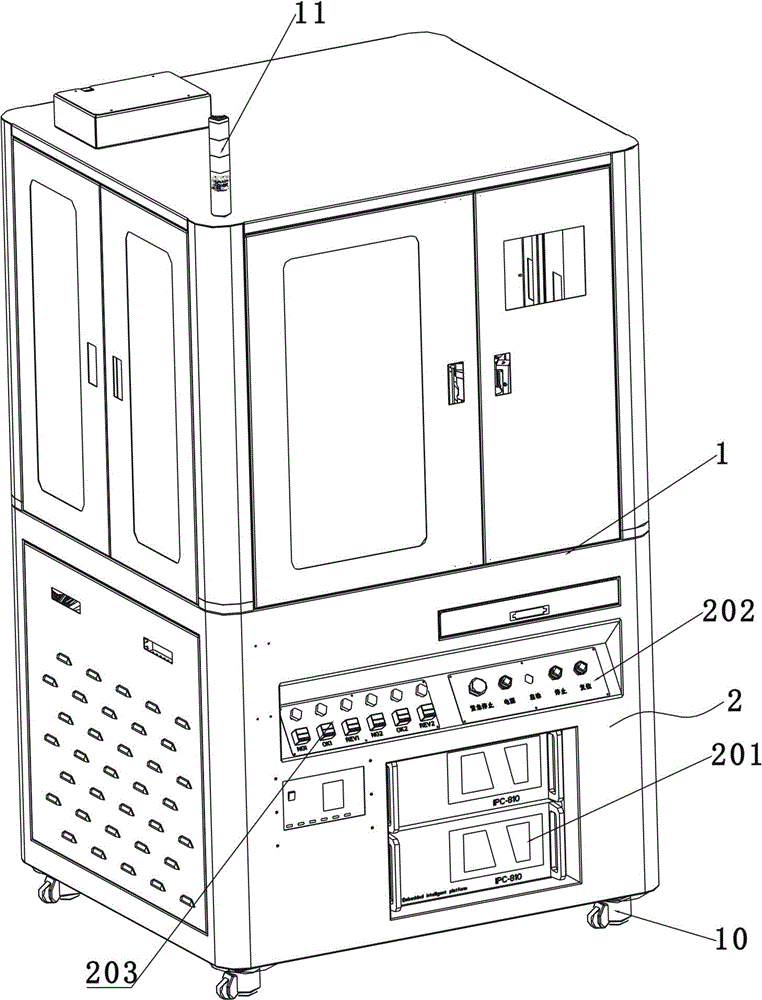

[0019] A particle six-sided inspection machine involved in the present invention includes a frame 1 and a control system 2. The control system 2 is integrated on the frame 1, and a feeding device and a material guide are fixedly installed on the frame 1. device and detection device, the feeding device is electrically connected with the control system 2, the feeding device is connected with the guide rail 6 through the guide rail 6, the detection device is electrically connected with the control system 2, and the detection device includes Position detection component 501, detector 502, described position detection component 501 is installed on one end of material guiding device, is provided with sorting device 7 at the other end of described material guiding device, and described sorting device 7 is fixedly installed on fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com