Bus bar for supporting high-power application of battery pack

A high-power, busbar technology, applied in the field of busbars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

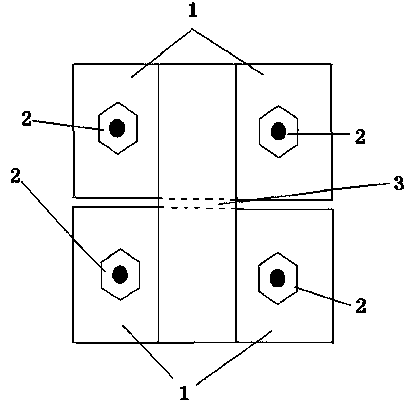

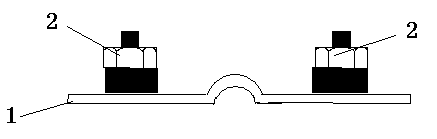

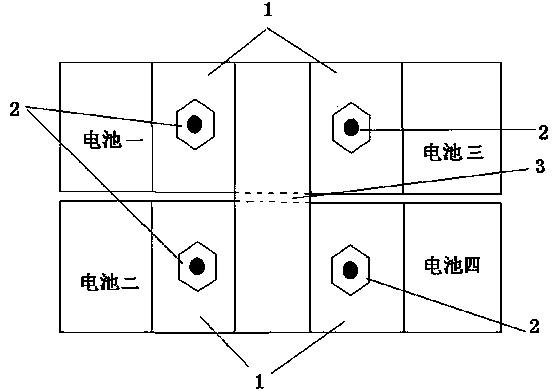

[0017] Such as figure 1 with 2 As shown, a bus bar supporting high-power applications of battery packs includes a plurality of conductive sheets 1, and each conductive sheet 1 is provided with a pair of connecting terminals 2, and the pair of connecting terminals 2 are arranged along the length of the conductive sheet 1. A section of the conductive sheet between the pair of connecting terminals 2 has an arc-shaped protrusion structure, the arc-shaped protrusion structure is arranged along the width direction of the conductive sheet 1, and the arc-shaped protrusion structure on the conductive sheet 1 is located between the two connecting terminals 2. In the center between the adjacent conductive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com