Spot facing tooling for non-horizontal end faces

A non-horizontal, end-face technology, applied to workpieces, manufacturing tools, metal processing equipment, etc., can solve the problems of hidden flight safety, cumbersome installation process, low work efficiency, etc., to simplify the installation process, easy to operate, and save the cumbersome process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

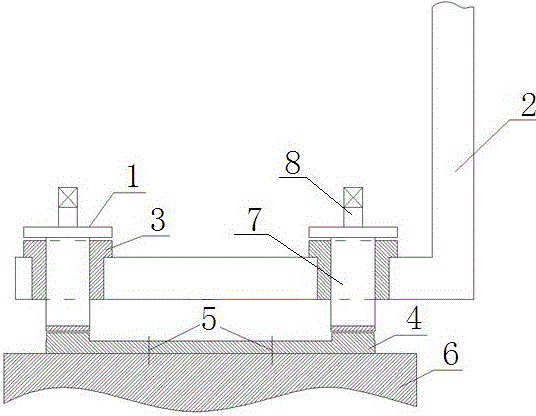

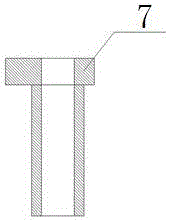

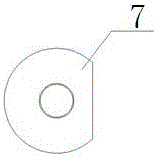

[0029] See Figure 1~Figure 2 Countersinking tooling for non-horizontal end faces, including end face countersink 1, frame locator 2, fixed bushing 3, integral pad with boss 4, rivet 5, flap cabin side rib 6, quick-change bushing 7 and inspection plug gauge 8. Among them, the fixed bushing 3 is provided on the frame positioner 2, the quick-change bushing 7 is fitted and installed on the fixed bushing 3, and the flap compartment side ribs 6 are predetermined by the frame positioner 2. Position the integral block 4 with a boss. The integral block 4 with a boss is provided with an initial hole for the installation of the piece. The positioning pin is inserted into the initial hole for the installation of the piece through the frame locator 2 to loc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com