Parallel flow evaporator core assembly tool

An evaporator, parallel flow technology, applied in the field of automobile manufacturing, can solve the problems of poor product consistency, core brazing "band spacing, and difficult operation, etc., to improve production efficiency and product quality, scientific and reasonable design, guarantee. The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

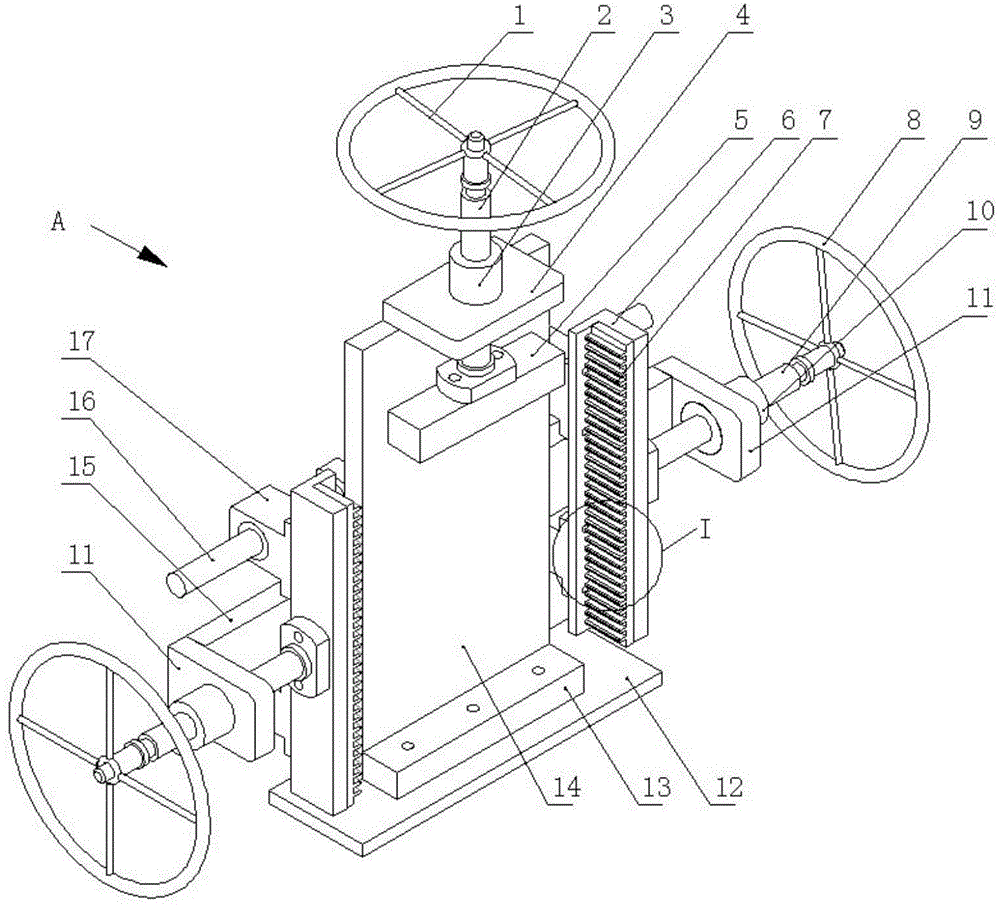

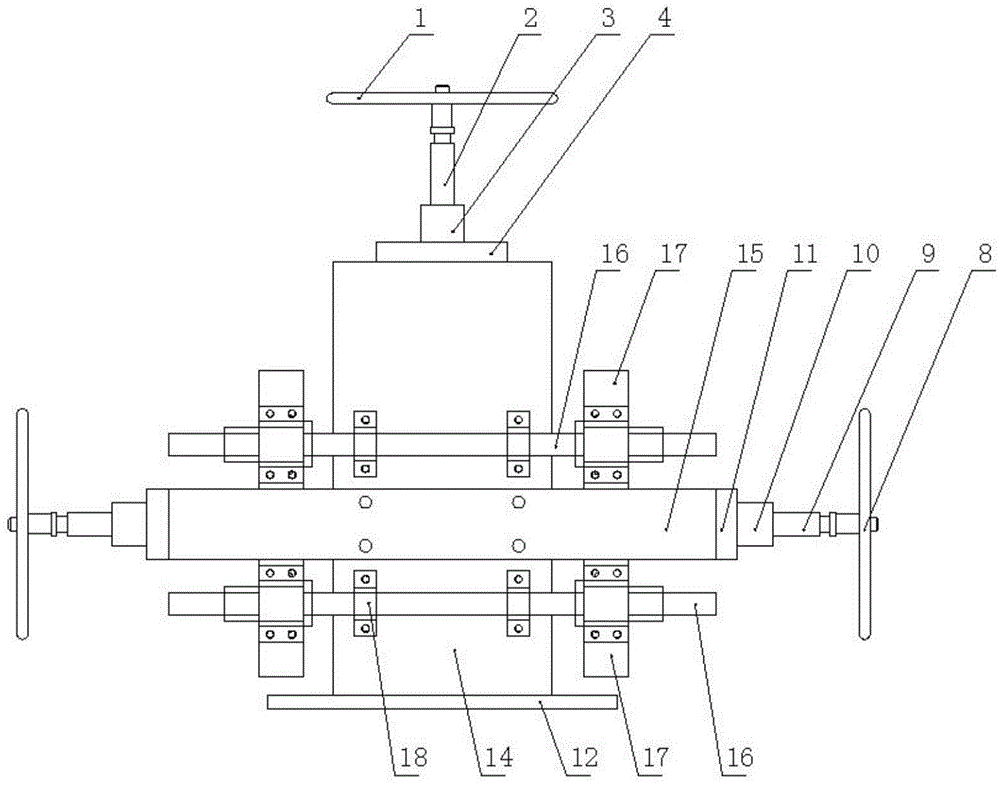

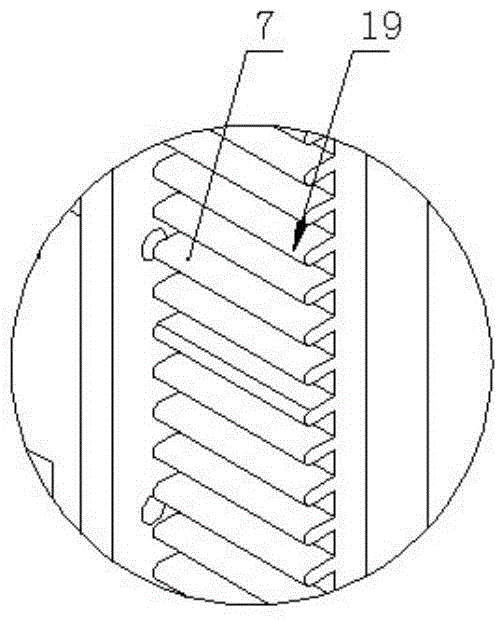

[0018] A parallel flow evaporator core assembly, such as figure 1 , figure 2 As shown, it includes a base plate 12, a vertical plate 14, a vertical drive assembly, a horizontal drive assembly, a linear optical axis 16, a pressing plate 5, and a comb 7. The vertical plate is fixed vertically on the bottom plate, and the vertical drive assembly is installed on the top of the vertical plate. The lower end of the vertical drive assembly is equipped with a pressure plate that can move up and down, the back of the vertical plate is fixed with a horizontal connecting plate 15, and the two ends of the horizontal connecting plate are respectively fixed with end plates corresponding to both sides of the vertical plate 11. The opposite outer sides of the two end plates are respectively symmetrically installed with horizontal drive comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com