Large-tonnage anti-marine corrosion metal damping and shock-absorbing steel support

A technology of corroding metals and large tonnage, applied in bridge parts, bridge materials, bridges, etc., can solve the problems of loss of horizontal restraint structure, disadvantage of arch bridges, etc., and achieve the effect of simple structure, avoidance of falling beams, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

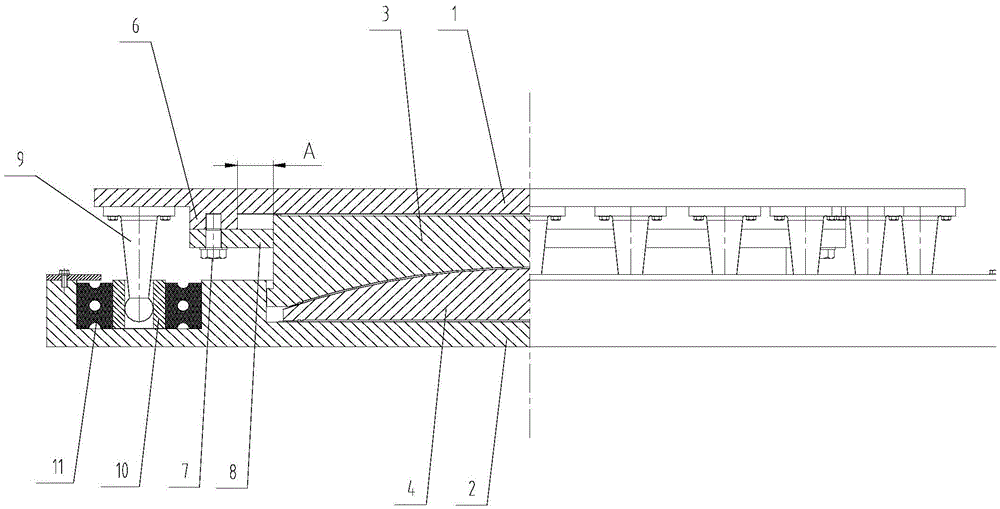

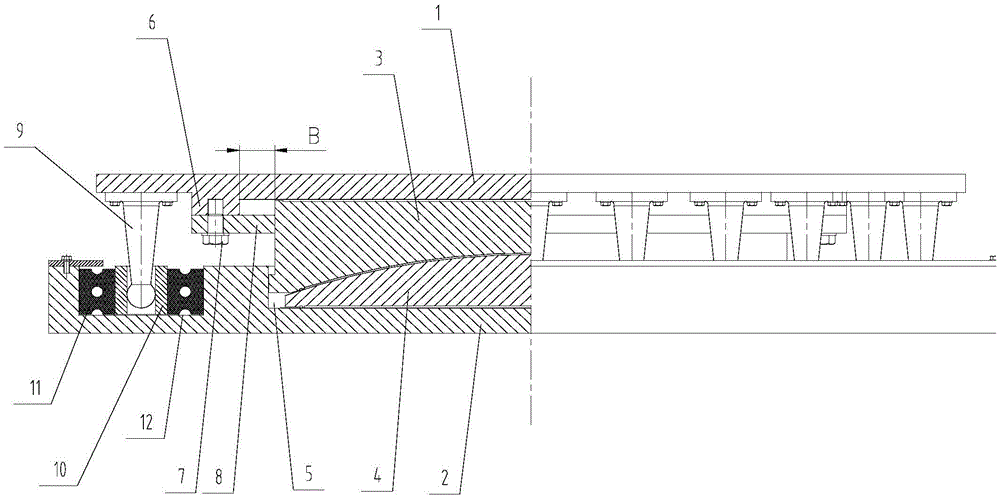

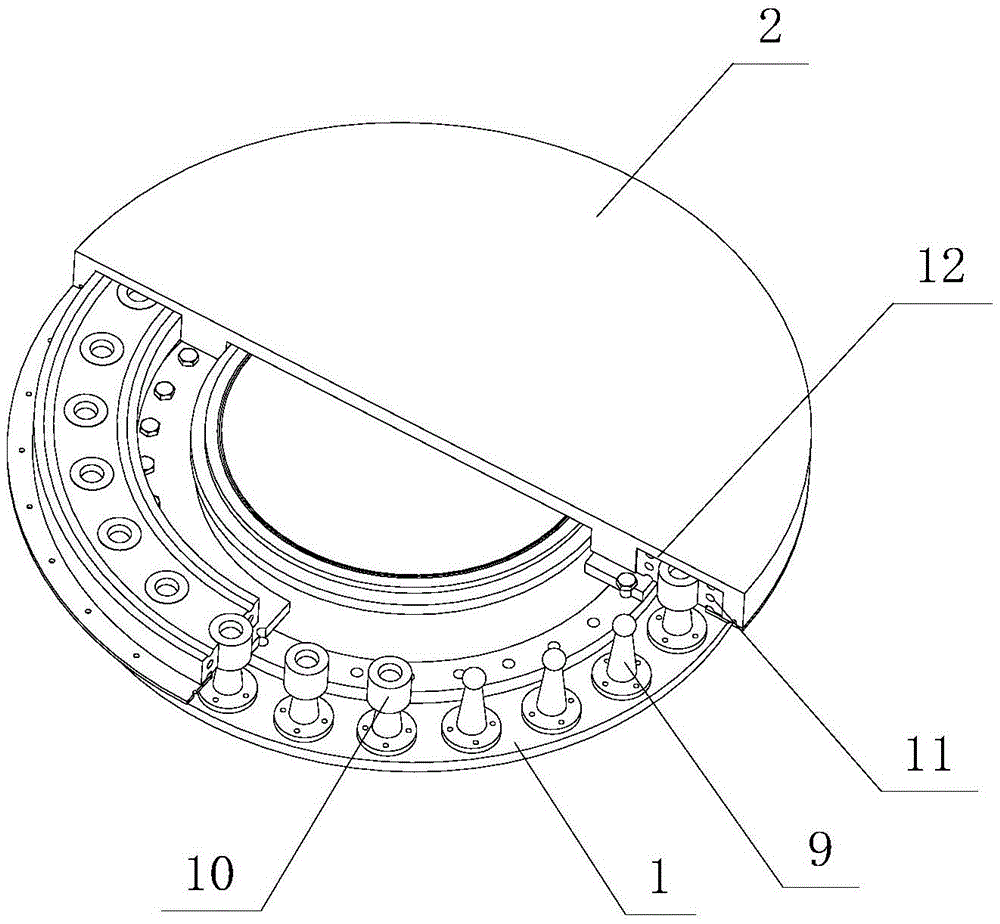

[0023] Such as Figure 1 to Figure 3 As shown, a large-tonnage anti-marine corrosion metal damping shock-absorbing steel bearing includes an upper bearing plate 1, a spherical crown lining plate and a lower bearing plate 2, and the spherical crown lining plate is installed on the upper bearing plate 1 and the lower bearing plate. Between the support plates 2, the spherical crown liner is composed of an upper liner 3 and a lower liner 4, the lower support plate 2 is provided with a liner installation groove 5, and the lower liner 4 is fixed in the liner installation groove In 5, the top of the upper liner 3 is fixedly connected to the upper support plate 1, the outer side wall of the bottom is in contact with the inner wall of the liner installation groove 5, the bottom surface of the upper liner 3 is slidingly fitted with the top surface of the lower liner 4, and the mating surface is a ball The crown surface; on the outer side of the upper liner 3, there is an anti-fall beam ...

Embodiment 2

[0029] see Figure 4 and Figure 5 , the difference between this embodiment and the first embodiment is that only the elongated damper installation groove is symmetrically opened on the lower support plate 2 opposite to the front and rear of the spherical crown liner, and the elastic element 11 is matched with the damper installation groove and installed In the groove, several installation holes are evenly opened on the elastic element 11, and the tenon sleeve 10 is assembled in the installation holes.

[0030] The support is only symmetrically arranged with metal dampers along the direction of the bridge.

[0031] The vertical bearing capacity of the above-mentioned large-tonnage anti-marine corrosion metal damping shock-absorbing and isolation steel bearing is 100,000kN. During normal operation, the displacement along the bridge is 0mm, and the displacement along the bridge is ±40mm. In case of accidental factors such as earthquakes, after the shear bolt 7 is destroyed, th...

Embodiment 3

[0033] see Figure 6 and Figure 7 , the difference between this embodiment and the first embodiment is that only the elongated damper installation grooves are symmetrically opened on the lower support plate 2 on the left and right sides of the spherical crown liner, and the elastic element 11 is matched with the damper installation grooves. Installed in the groove, several installation holes are evenly opened on the elastic element 11, and the tenon sleeve 10 is assembled in the installation holes.

[0034] The support is only symmetrically arranged with metal dampers in the direction of the transverse bridge.

[0035] The vertical bearing capacity of the above-mentioned large-tonnage anti-marine corrosion metal damping shock-absorbing and isolation steel support is 100,000kN. During normal operation, the displacement along the bridge is ±300mm, and the displacement along the bridge is 0mm. In case of accidental factors such as earthquakes, after the shear bolt 7 is destroy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com