Rubber bearing

A technology of rubber bearings and bearing sleeves, which is applied in the field of bearings, can solve the problems of rubber linings falling off easily, and achieve the effects of preventing friction from increasing, eliminating force falling off, and reducing static friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

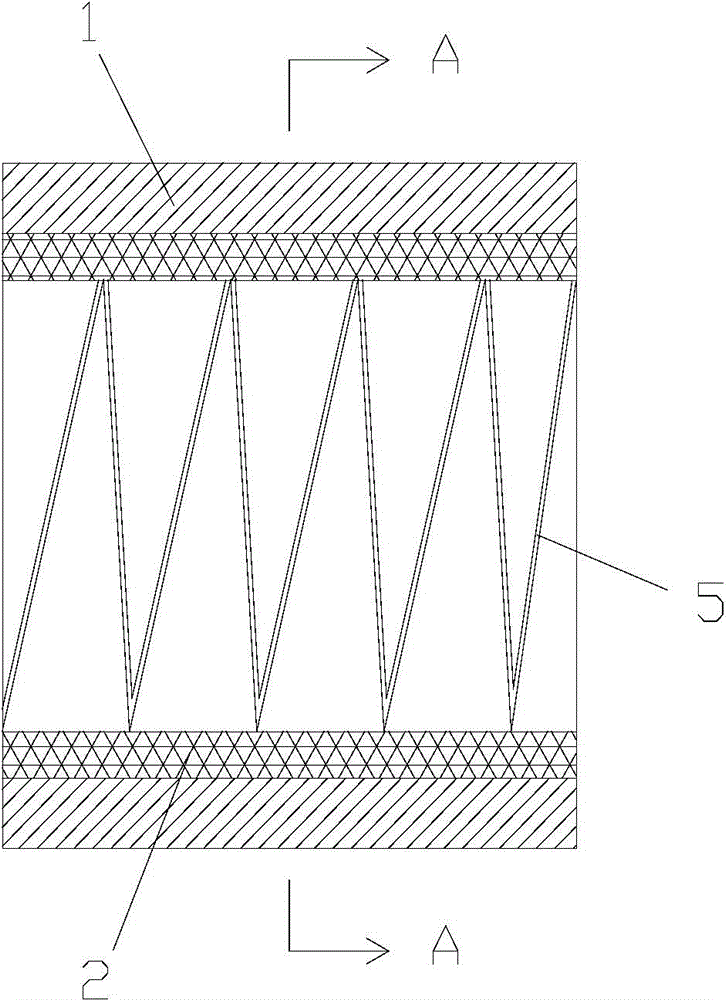

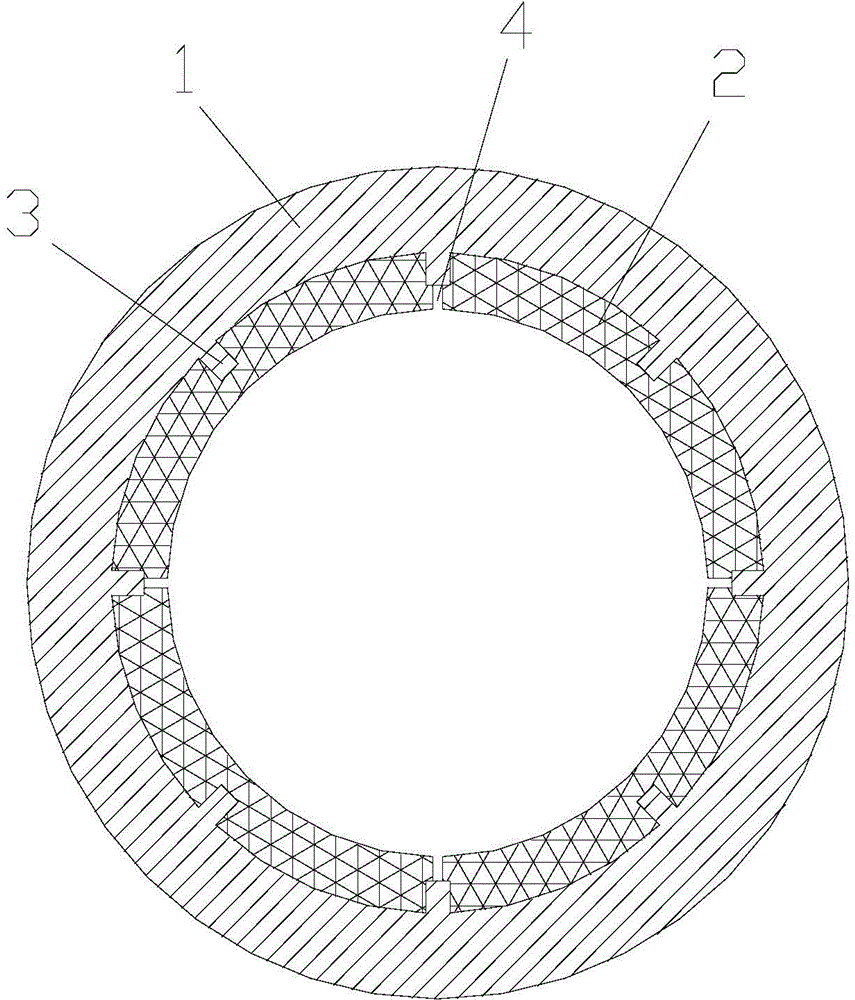

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] As shown in the figure, the rubber bearing of this embodiment includes a metal bearing sleeve 1 and a rubber bushing 2 arranged in the metal bearing sleeve. Convex 3.

[0014] In the rubber bearing of this embodiment, the anti-loosening protruding strips provided can provide the rubber bushing with a thrust in the circumferential direction during operation, thereby offsetting the frictional force exerted by the rotating shaft on the rubber bushing in the circumferential direction, and avoiding the friction between the rubber bushing and the metal bearing. There is a tendency of relative movement between the sleeves, which reduces the static friction between the two, thereby eliminating the problem that the rubber lining falls off under force during use.

[0015] As an improvement to this embodiment, the rubber bushing is composed of four-lobed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com