Friction reducing structure for front shock damper

A front shock absorber and friction reduction technology, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve problems such as inability to guarantee comfort and safety, sticking, and large friction, and achieve The effect of ensuring comfort and safety and reducing the possibility of sticking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

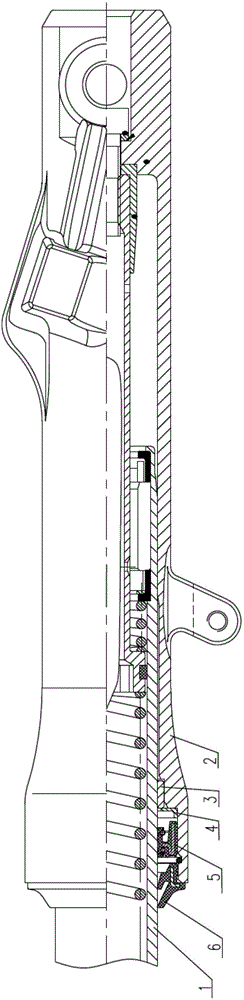

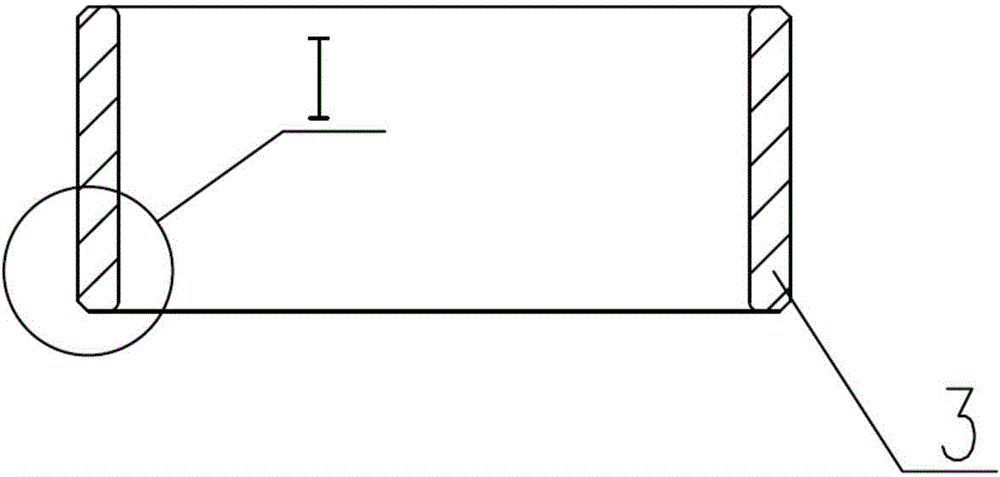

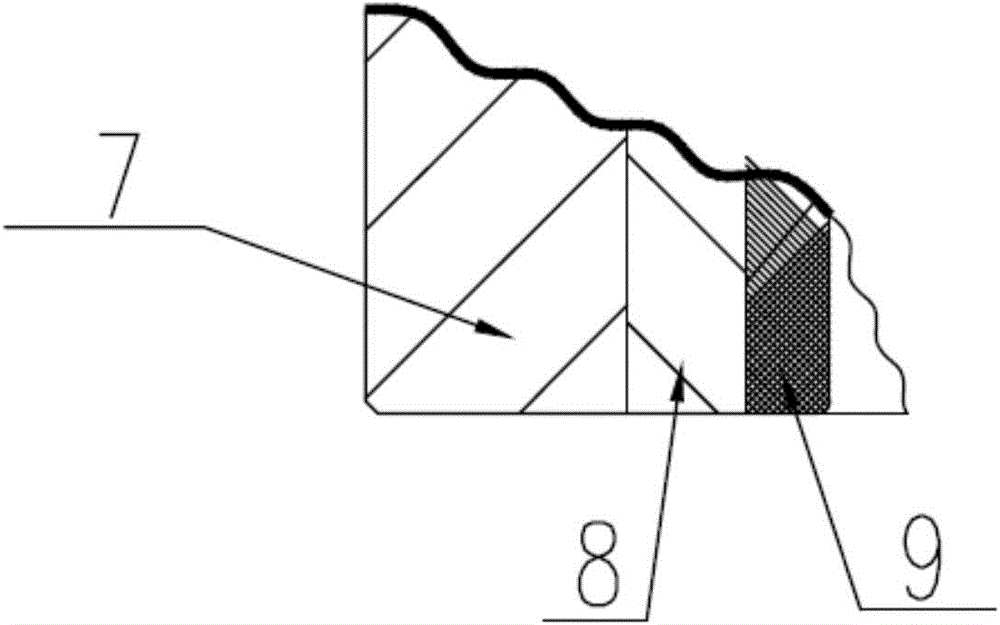

[0029] like figure 1 As shown, the present invention provides a friction-reducing structure of a front shock absorber, which includes a bottom cylinder 2 and a fork tube 1 installed in the bottom cylinder. Composite sleeve 3, fork pipe 1 passes through composite sleeve 3 and is installed in bottom cylinder 2, and fork pipe 1, composite sleeve 3 and bottom cylinder 2 are installed on the same axis. The axial width of the groove is equal to the axial width of the composite sleeve 3. In order to reduce the stagnation between the fork tube 1 and the bottom cylinder 2, the thickness of the composite sleeve 3 is greater than the height of the groove. In this way, the outer wall of the fork tube 1 and the bottom cylinder 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com