Accurate pressure balance valve for makeup water tank of internal combustion engine and its control method

A technology for supplying water tanks and control methods, applied in the direction of balance valves, valve devices, safety valves, etc., to achieve the effect of improving stability and efficiency and preventing instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

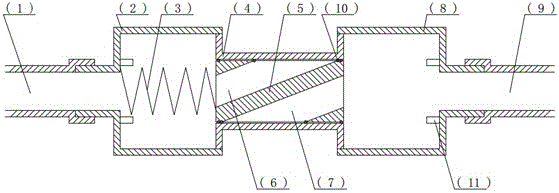

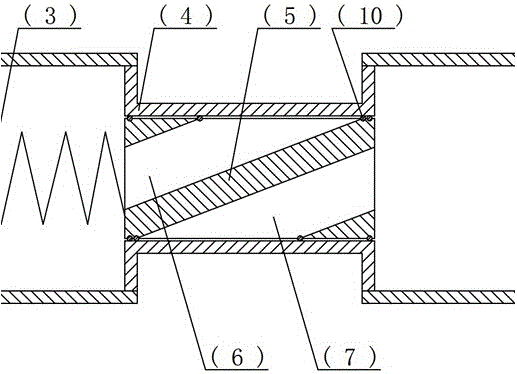

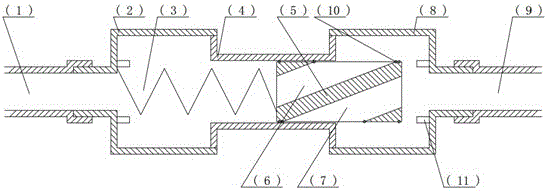

[0013] refer to figure 1 with figure 2 , the parallel pipe pressure balance valve for internal combustion engine supply water tank includes supply water tank 1, left water chamber 2, spring 3, valve body 4, valve core 5, right waterway 6, left waterway 7, right water chamber 8, radiator Waterway 9, sealing ring 10, backstop column 11; the left end of the left water chamber 2 is provided with a supply water tank 1, the right end of the left water chamber 2 is connected with the left end of the valve body 4, the right end of the valve body 4 is connected with the left end of the right water chamber 8, and the right water chamber The right end of 8 is connected with the radiator 9, and the left side of the left water chamber 2 and the right side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com