Cable pipe fitting spiral gathering connector

A connector, Guangji technology, applied in the direction of electrical components, pipes/pipe joints/pipe fittings, pipes, etc., can solve the problems of poor durability, less connection, narrow adaptation surface, etc., achieve simple manufacturing, eliminate axial movement, Use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

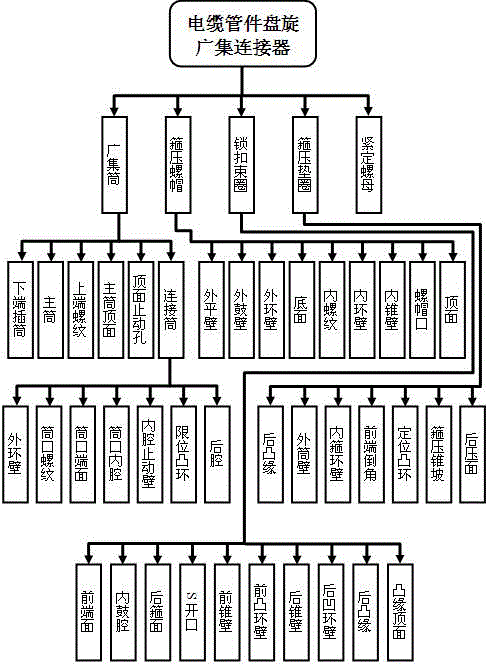

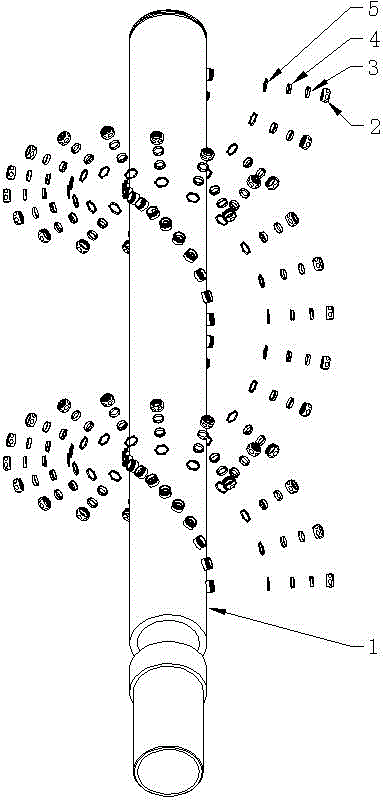

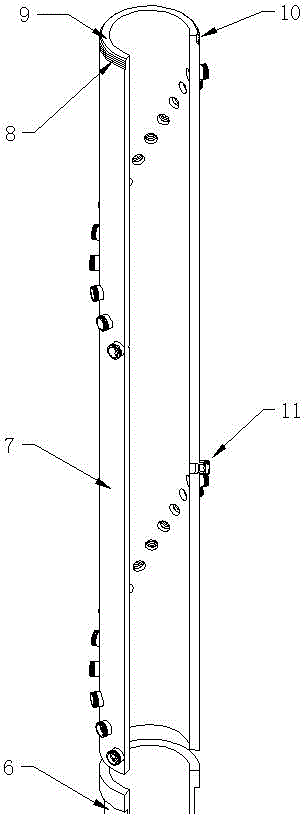

[0041] As a technical proposal for product manufacturing, the present invention can make the proposal concretely implemented through the organic combination of corresponding organizational structures. The product organization structure of an embodiment of the present invention is as follows: figure 1 shown.

[0042] figure 1 Among them, the product is composed of five parts: Guangji cylinder, clamp nut, lock ring, clamp washer and set nut. Among them, the structure of Guangji cylinder parts includes lower end insert sleeve, main cylinder, upper end thread, The top surface of the main cylinder, the stop hole on the top surface, and the connecting cylinder are composed of five parts. The structure of the clamping nut parts includes the outer flat wall, the outer drum wall, the outer ring wall, the bottom surface, the inner thread, the inner ring wall, the inner cone wall, There are nine components of the nut mouth and the top surface. The structure of the lock ring part includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com