Combined measuring scale

A combined metering and weighing bucket technology, which is applied in the field of packaging machinery and equipment, can solve the problems that are difficult to meet the level requirements of high-speed production lines, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

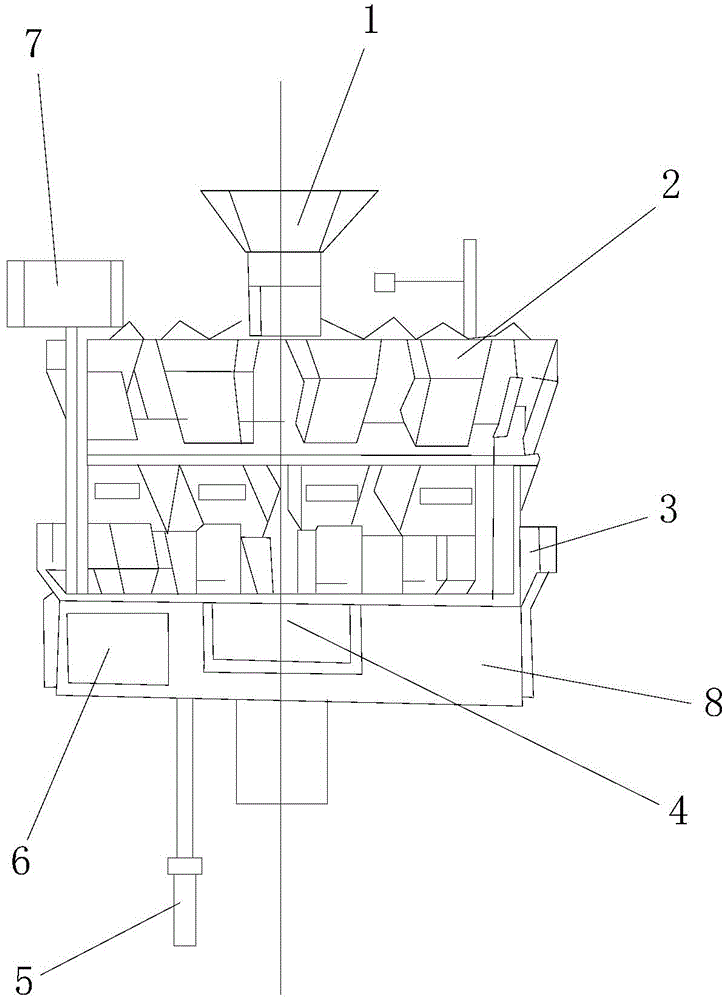

[0011] Such as figure 1 The shown combined weighing scale includes a central hopper 1 and a sub-hopper 2. The sub-hopper 2 is arranged directly below the central hopper 1, and 9 to 14 weighing hoppers 3 are arranged below the sub-hopper 2. The weighing buckets 3 are arranged horizontally and radially, and the bottom of the weighing bucket 3 is provided with a supporting shell 8, and the inside of the supporting shell 8 is provided with a weighing computer 6, the weighing computer 6 and the control mechanism 5. In connection, a display board 4 is provided on the surface of the support shell 8, and a quality selection input device 7 is also provided above the hopper 2.

[0012] The central hopper 1 has a conical structure.

[0013] The invention has a simple structure. Materials enter the dividing hopper and each weighing hopper from the central hopper. Each weighing hopper is equipped with a weight sensor, which can accurately measure the quality of the material in each hopper. Me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap