Temperature measuring system and method of electric heating glass

A technology for electrically heating glass and temperature measurement, which is applied to thermometers, thermometers, and measuring devices that use electrical/magnetic components that are directly sensitive to heat, and can solve problems affecting the appearance and optical performance of automobiles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

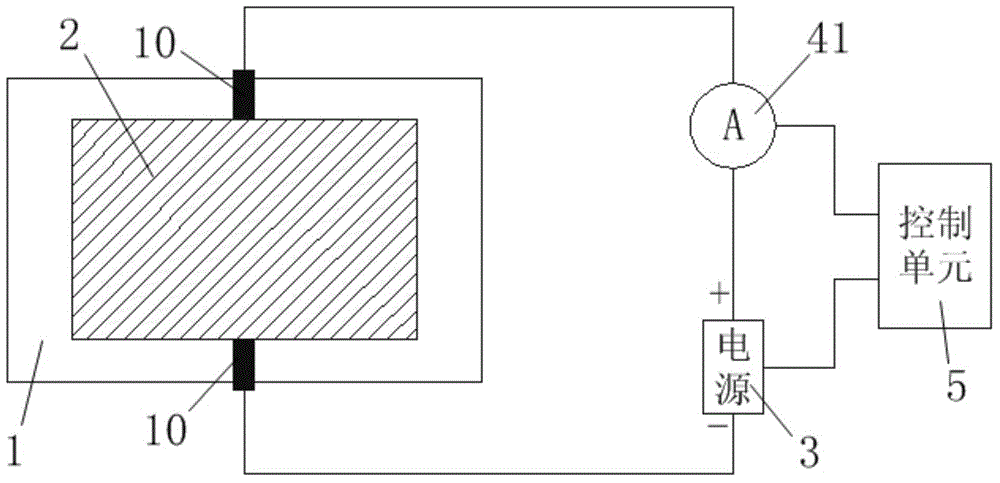

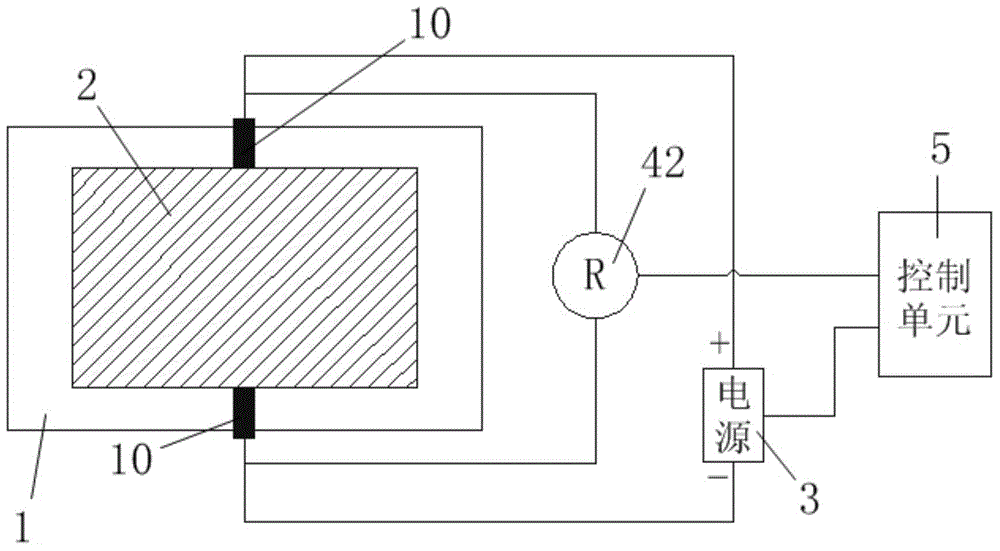

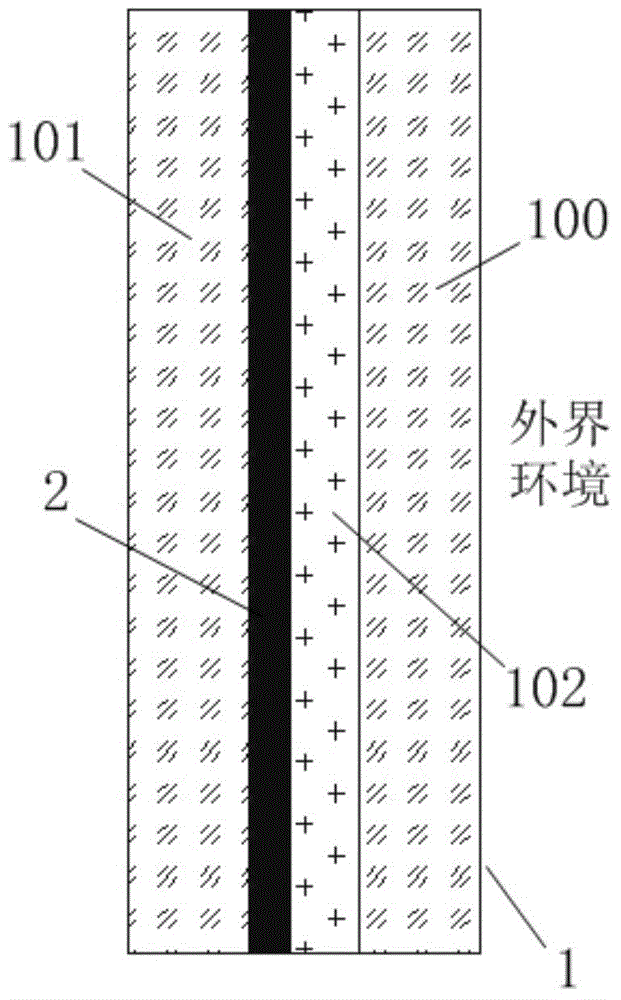

[0039] Such as figure 1 with figure 2 As shown, the temperature measurement system for electrically heated glass of the present invention includes a glass plate 1, an electric heating element 2 and a power source 3. The electric heating element 2 is arranged on the surface of the glass plate 1, and the electric heating element 2 can be The glass plate 1 is heated by energizing and heating. The power supply 3 can load a voltage U on both ends of the electric heating element 2. It is characterized in that it also includes a current measuring device or a resistance measuring device, which can measure the electric heating element 2 The current I or resistance R after being energized; in this way, by directly setting the current measuring device or resistance measuring device in the energized loop formed by the electric heating element 2 and the power supply 3, the current or resistance of the electric heating element 2 is directly measured, and the electric The temperature coeffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com