Flexible substrate stacking and packaging structure and flexible substrate stacking and packaging method

A technology of flexible substrates and packaging structures, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as bending circuit layer damage, product stacking failure, etc., to ensure effectiveness and stability, and avoid circuit layer failure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

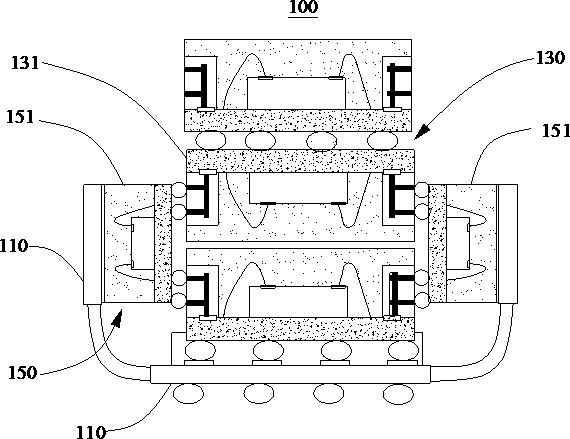

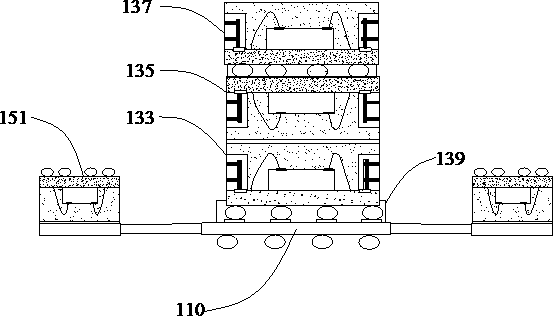

[0056] see in conjunction Figure 1 to Figure 4 , this embodiment provides a flexible substrate stack package structure 100, which is applied to the device package of the flexible substrate, and can avoid the problem of failure of the circuit layer caused by the bending of the flexible substrate 110 while ensuring the number of device stack packages, and ensures the stacking. effectiveness and stability.

[0057] The flexible substrate stack package structure 100 provided in this embodiment includes a flexible substrate 110, a first device package assembly 130 and a second device package assembly 150, the first device package assembly 130 is mounted on the middle of the flexible substrate 110, and is connected to the flexible substrate 110 is electrically connected, and the second device package assembly 150 is insulated and mounted on the side wings of the flexible substrate 110; wherein, the side wings of the flexible substrate 110 are turned upwards so that the second devic...

no. 2 example

[0080] see Figure 5 , an embodiment of the present invention provides a flexible substrate stack packaging method for preparing the flexible substrate stack packaging structure 100 described in the first embodiment, the method includes the following steps:

[0081] S1: Mount the first device package assembly 130 on the middle of the flexible substrate 110 .

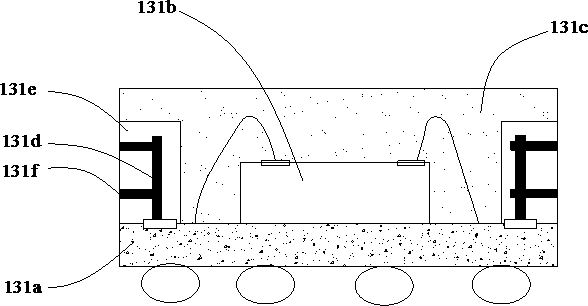

[0082] Specifically, it is necessary to prepare the front-mounted IC devices 131 first, and stack a plurality of front-mounted IC devices 131 in the middle of the flexible substrate 110 in order to form the first device package assembly 130, wherein every two adjacent front-mounted IC devices 131 are reversed. stack.

[0083] In this embodiment, a plurality of positively mounted IC devices 131 includes a first IC device 133, a second IC device 135, and a third IC device 137. When step S1 is performed, the first IC device 133 is first mounted on the flexible substrate 110 and fill the bottom of the first IC device 133 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com