A contact system with automatic arc blowing function

A contact system and moving contact technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of the circuit breaker not breaking normally, accelerating the arc into the arc extinguishing chamber, etc., to improve the short-circuit breaking capacity, simple structure, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

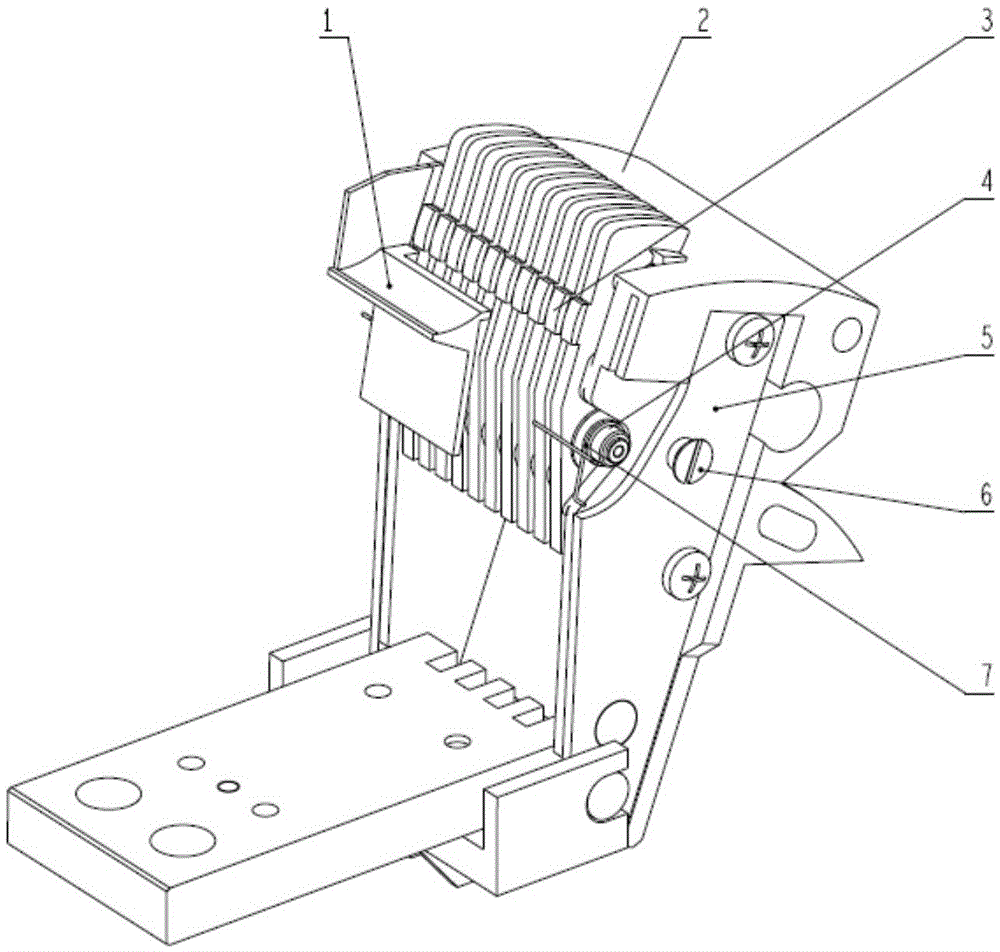

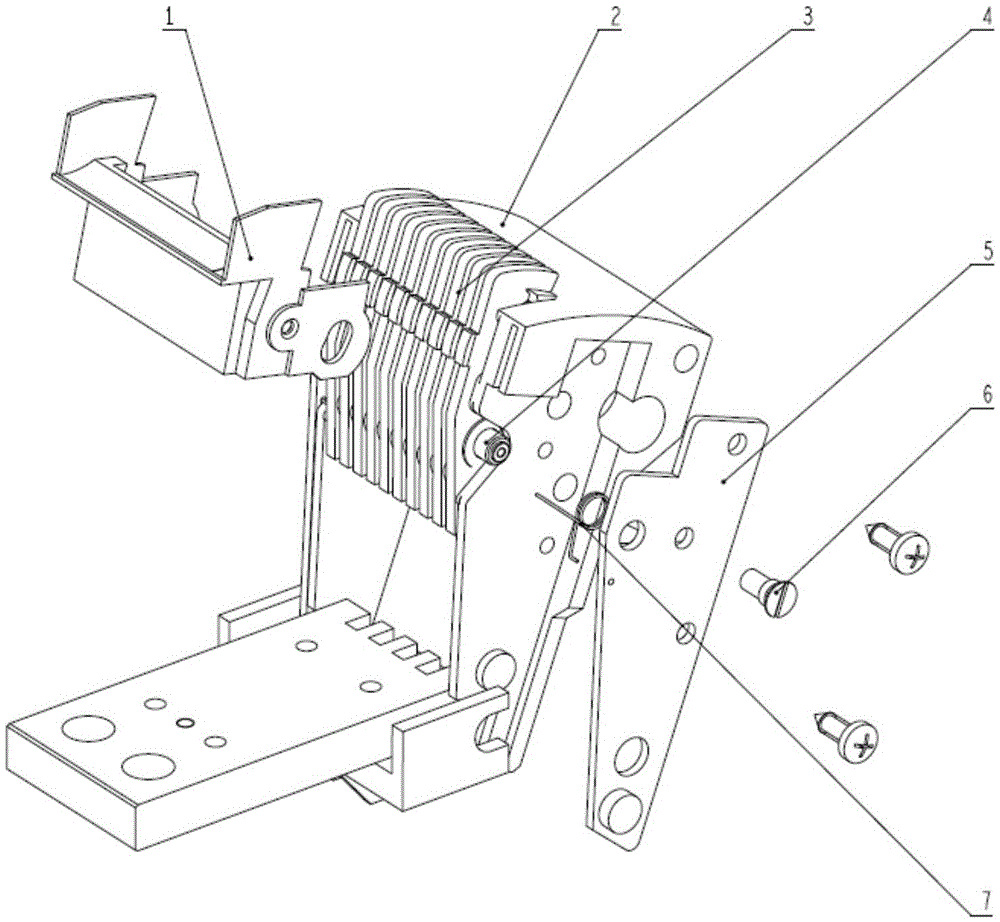

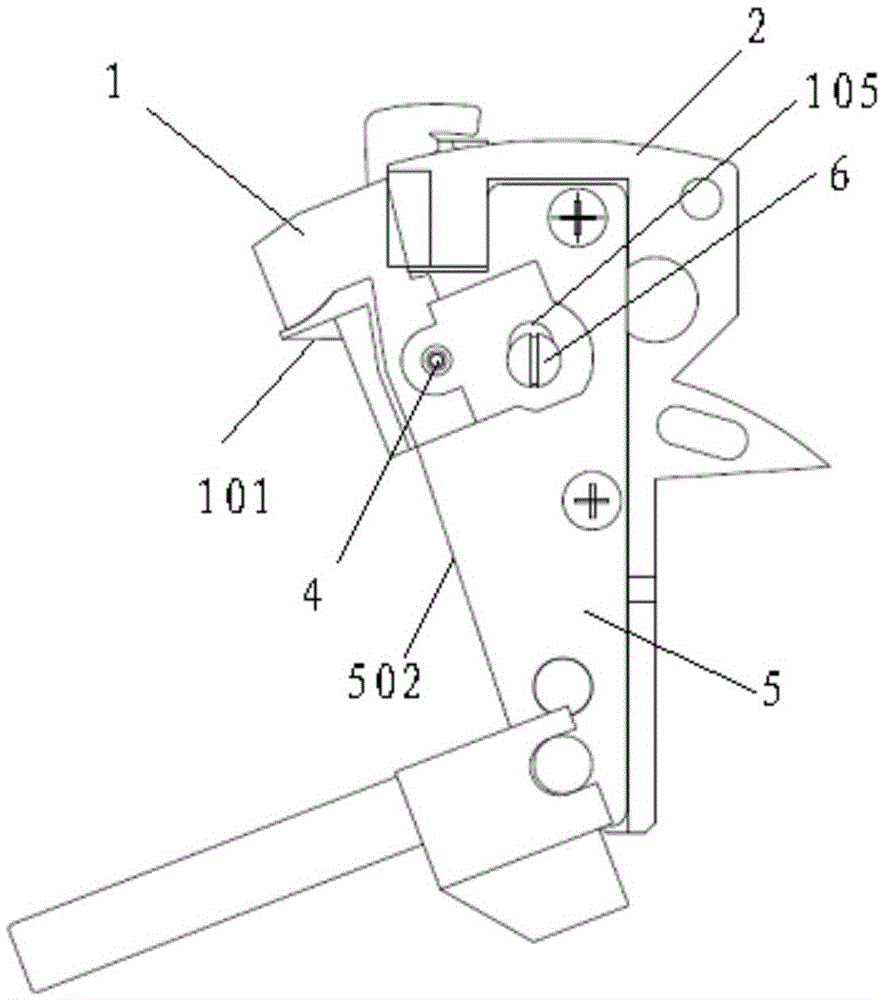

[0038] Such as figure 1 , figure 2 and Figure 5 As shown, this embodiment provides a contact system with automatic arc blowing function, which is suitable for application in circuit breakers with arc extinguishing chambers, such as low-voltage circuit breakers and frame circuit breakers. The contact system in this embodiment is suitable for being arranged under the arc extinguishing chamber, and the contact system includes a contact support 2 and a movable contact 3 which is arranged on the contact support 2 and can be rotated together with the contact support 2 , the moving contact 3 has a maximum opening distance when the brake is turned off.

[0039]The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com