Motor rotor and cable connection structure thereof

A technology for connecting structures and motor rotors, applied in the direction of magnetic circuit shape/style/structure, electrical components, electromechanical devices, etc., can solve the problems of high centrifugal force, torn off cables and winding lead wires, and low reliability of motor safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

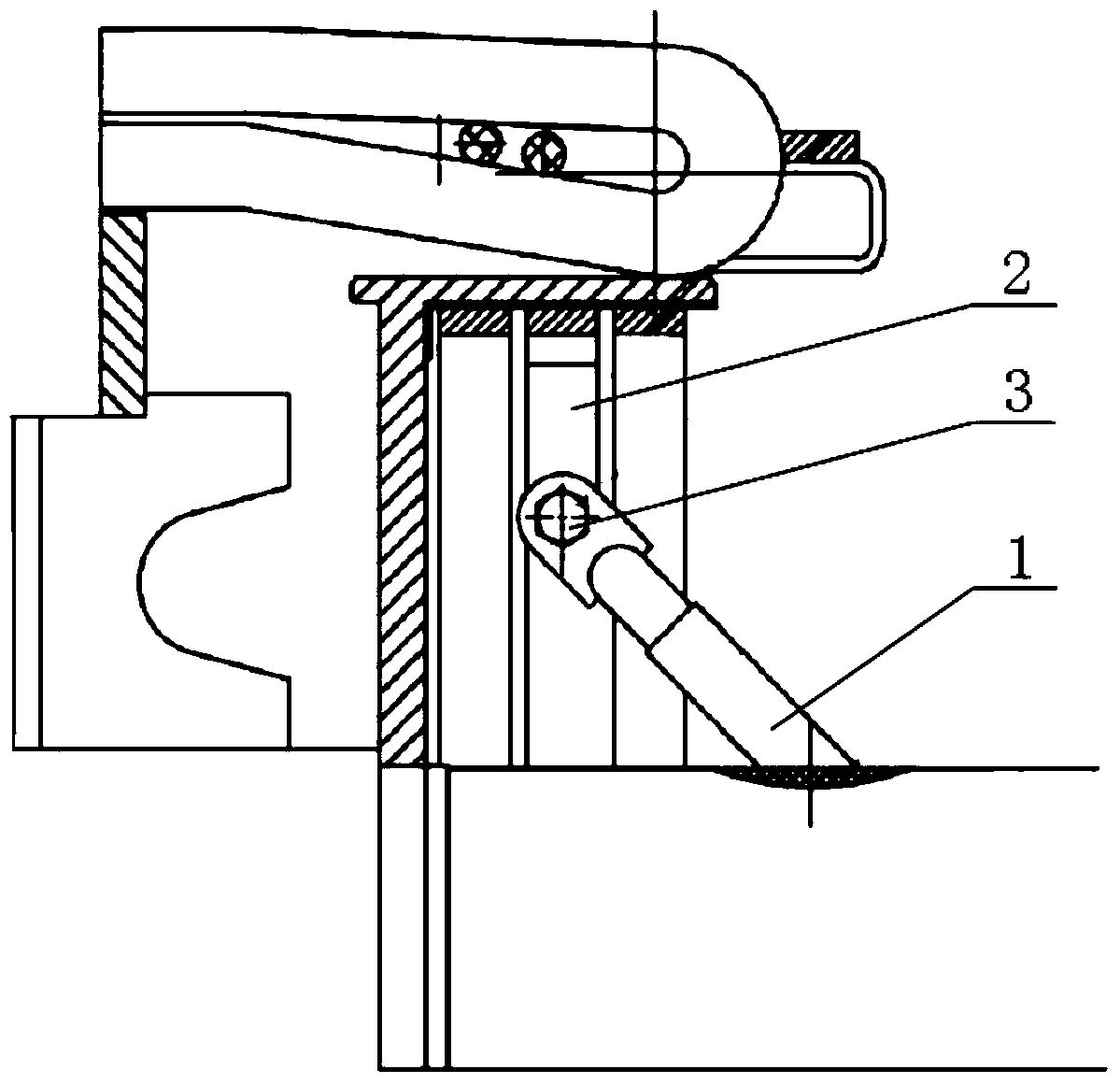

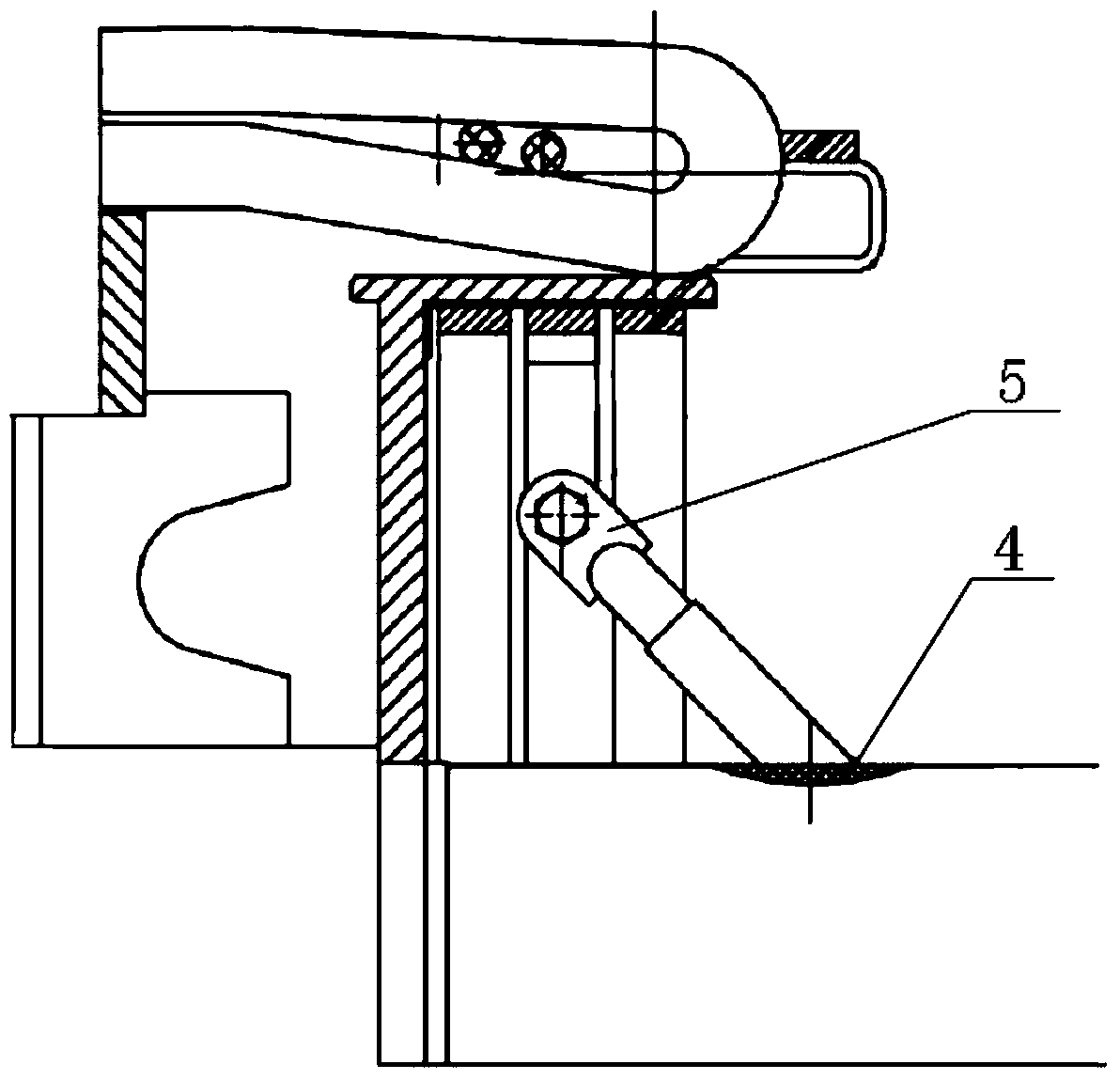

[0029] The second specific embodiment provided by the present invention is improved on the basis of the first specific embodiment, specifically: felt 4 and insulating material 5 are added.

[0030] In the second specific embodiment provided by the present invention, in order to ensure the quality of the lead-out cable 1 , in this embodiment, a felt 4 is provided at the threading hole, and the felt 4 covers the edge of the threading hole. As mentioned above, the lead-out cable 1 is mainly a three-phase cable drawn out from the motor shaft, and when drawn out from the motor shaft, a hole is often opened on the shaft, called a threading hole. The size of the threading hole is equivalent to the size of the lead-out cable 1, so that the lead-out cable 1 can pass through the threading hole smoothly. However, due to machining errors and inherent defects in hole processing methods, there are often large or small sharp corners or uneven burrs at the opening of the threading hole, and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com