Low-temperature stop valve

A shut-off valve, low temperature technology, applied in valve details, diaphragm valves, valve devices, etc., can solve the problems of the shut-off valve being unable to adjust the shut-off conduction effect, poor practicability, etc., to improve the working efficiency of the pump fluid, convenient switching, excessive smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

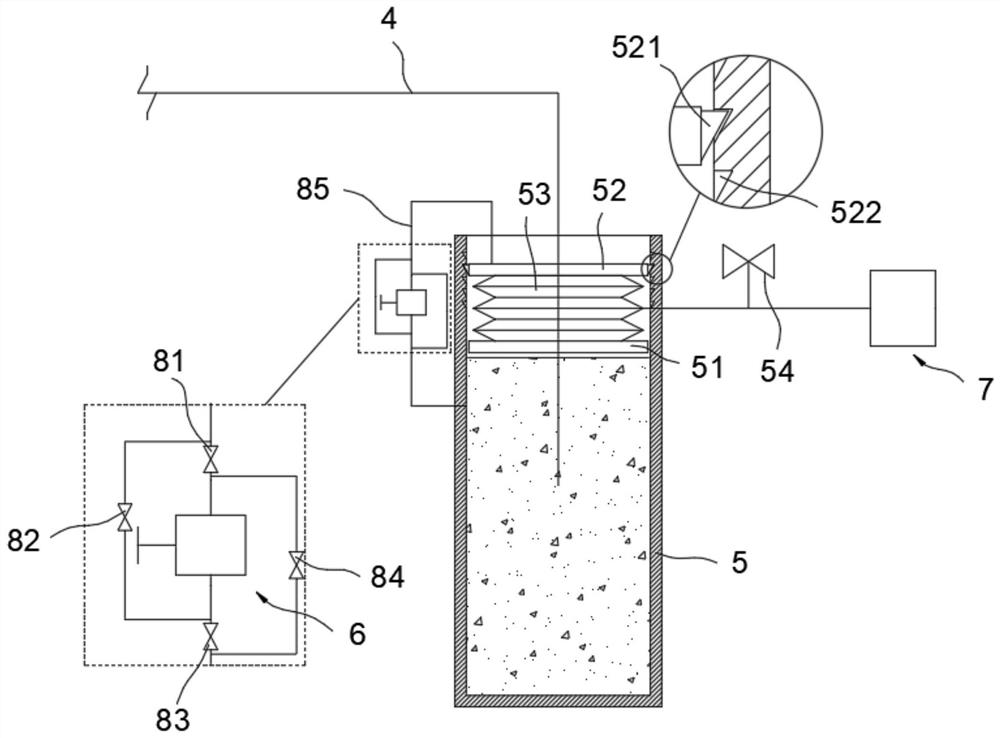

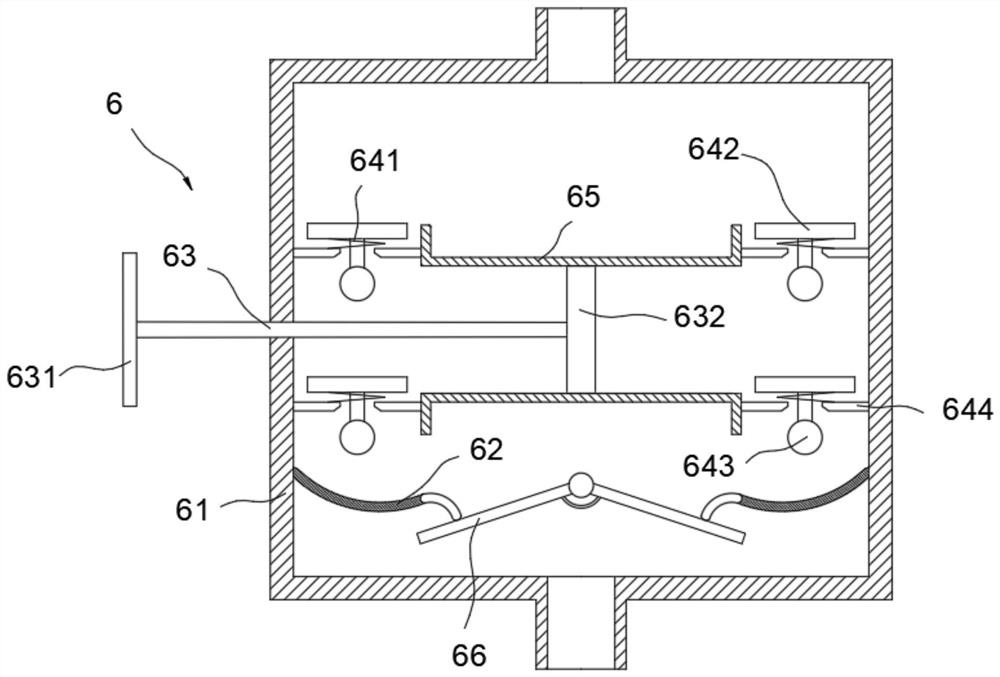

[0036] Embodiment: When the device is working, the valve body 1 is fed with water flow, and the valve rod 2 can control the opening of the elastic valve ball 3 through the hydraulic control device 5, thereby controlling the opening and closing of the valve, avoiding Remove the time-consuming and labor-intensive problems caused by manual control; the thermal expansion and cold contraction air terminal 9 is connected to the input terminal that needs to be adjusted according to the temperature. At this time, the thermal expansion and cold contraction properties will be reflected by the air. The pressure increases and presses the upper extruding piece 52 downward. At this time, the upper extruding piece 52 moves downward and shrinks the space of the folded part 53, and then the folded part 53 pushes the lower extruded piece to move, so that the inside of the square housing The space shrinks, and the pressure control liquid in the square shell is pumped into the interior of the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com