Magnetic pole assembling tool of external rotor motor

An external rotor motor and assembly tooling technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of easily damaged magnetic poles, difficult magnetic pole movement, time-consuming and labor-intensive, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

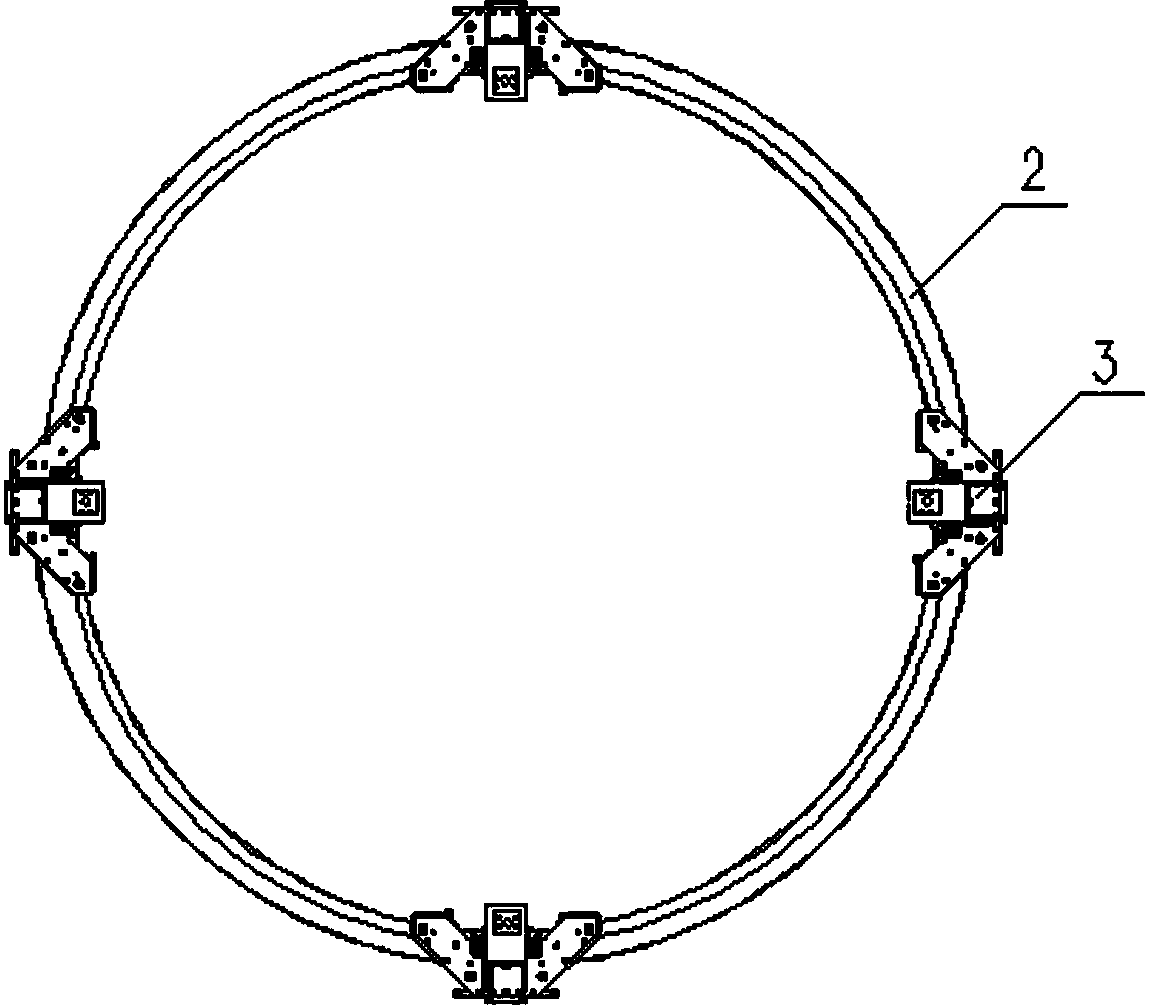

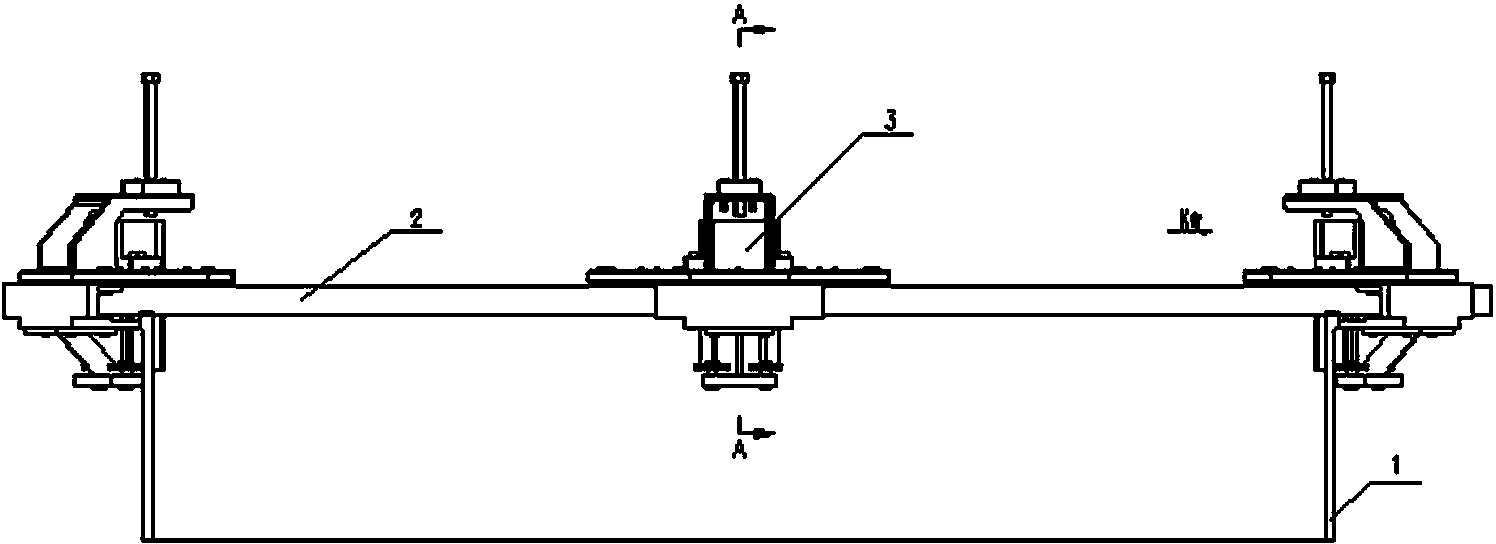

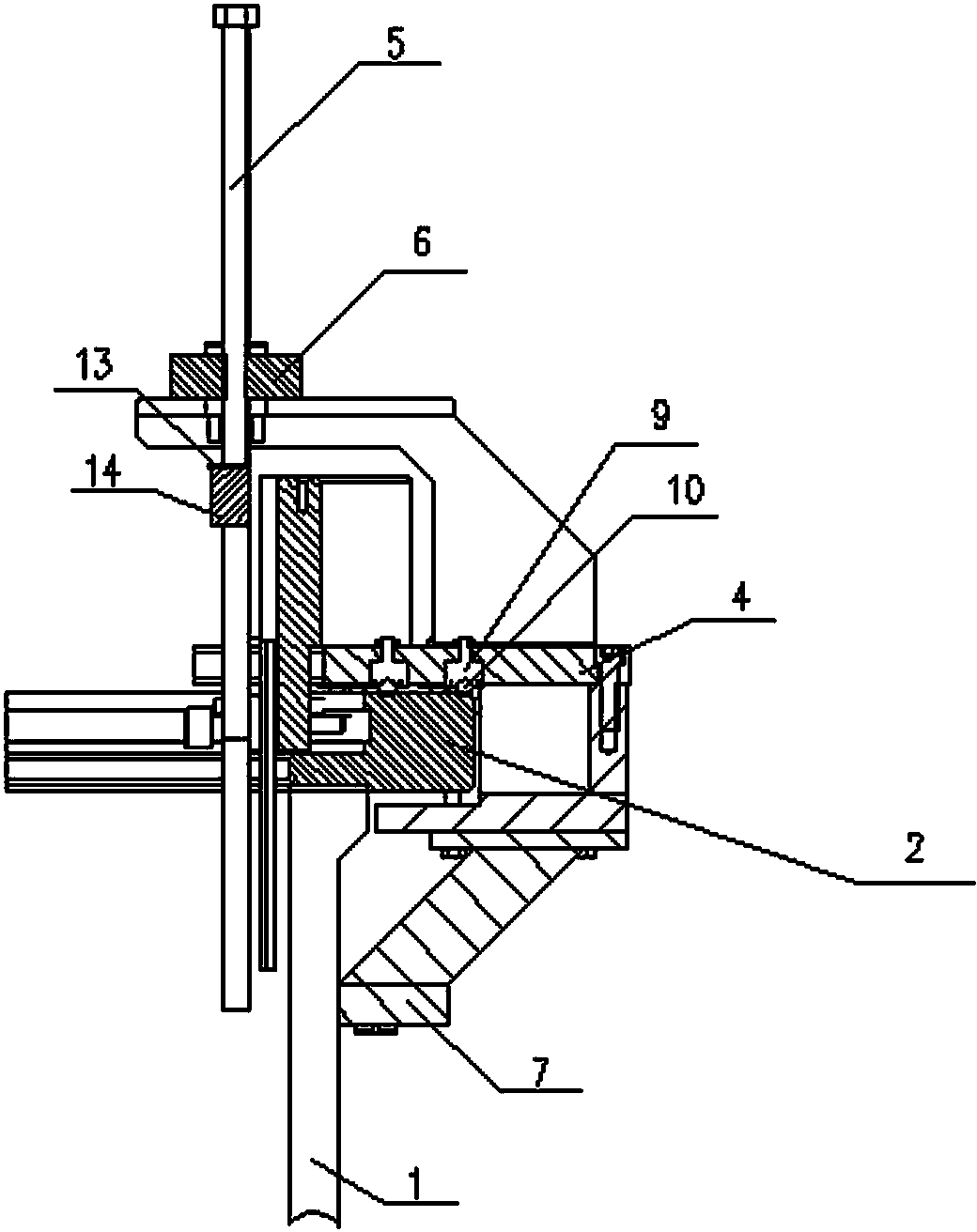

[0017] Referring to the accompanying drawings, a magnetic pole assembly tool for an outer rotor motor includes a support guide rail 2 and a magnetic pole assembly clamp 3. The support guide rail 2 is circular, and one end of the support guide rail 2 is fixed to one end of the outer rotor 1. The support guide rail 2 The inner diameter of the outer rotor 1 matches the inner diameter; the magnetic pole assembly clamp 3 includes a support plate 4, a magnetic pole pressing screw 5, and a threaded block 6, and one end of the magnetic pole assembly clamp 3 is provided with a support plate 4, and on the outside of the support plate 4 The end is provided with a threaded block 6 and a matching magnetic pole screw 5, the magnetic pole 14 to be assembled is placed inside the threaded block 6, and the magnetic pole screw 5 is mounted to the corresponding position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com