Duplex stainless steel

一种双相不锈钢、选自的技术,应用在双相不锈钢领域,能够解决应力腐蚀裂纹、厚度减薄等问题,达到优异耐受性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

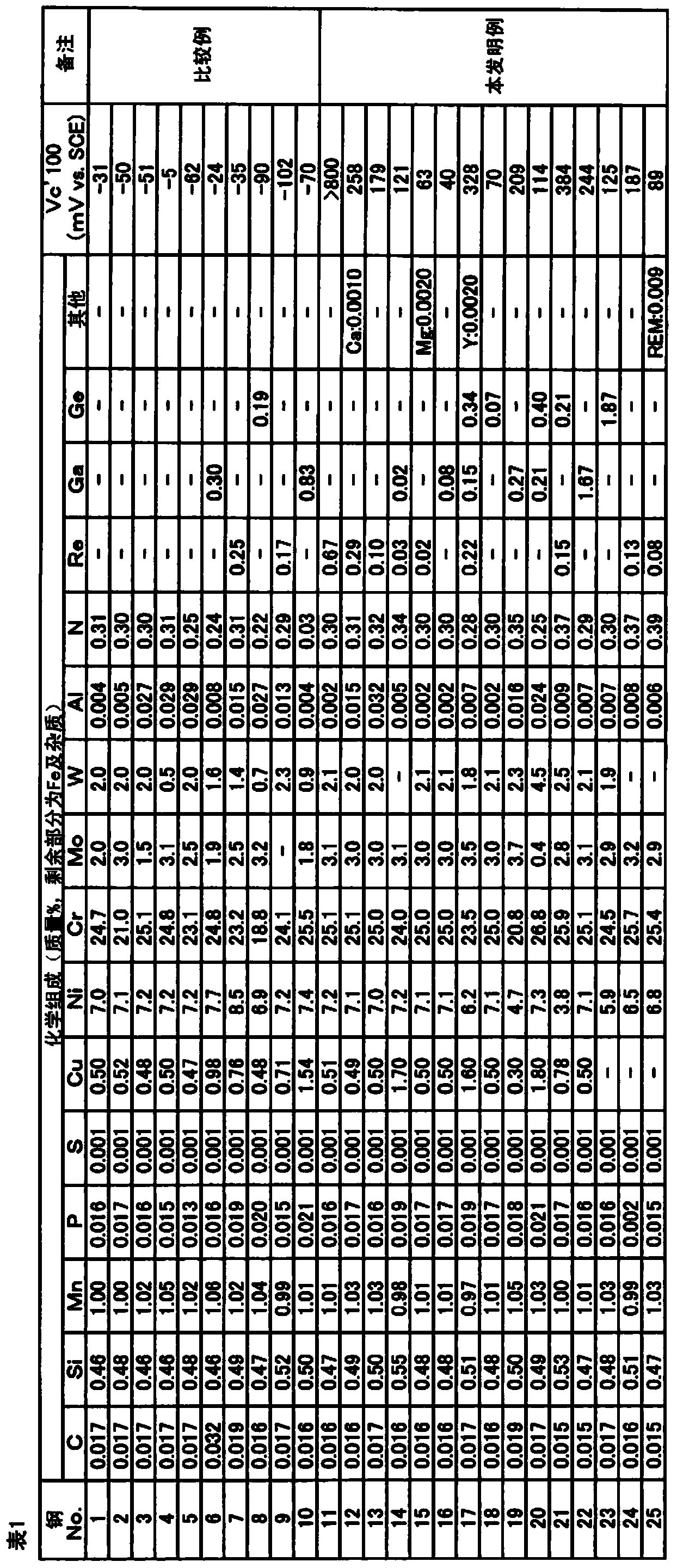

[0068] Steel Nos. 1 to 25 having the chemical compositions shown in Table 1 were each melted in a 50 kg vacuum melting furnace, and the obtained steel ingots were heated at 1200° C., forged and hot rolled, and processed into raw materials with a thickness of 5 mm.

[0069]

[0070] Next, the obtained raw material was subjected to a solution heat treatment at 1070° C. for 5 minutes, and then machined to produce a test piece (diameter: 15 mm, thickness: 2 mm) for evaluating corrosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com