Rear stop and no-go gauge device of bending machine

A back gauge and bending machine technology, which is applied in the field of back gauge stop gauge devices for press brakes, can solve the problems of poor adjustment accuracy, inconvenient operation, and high processing accuracy requirements, achieve simple assembly, and reduce manufacturing and labor costs. , the effect of flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

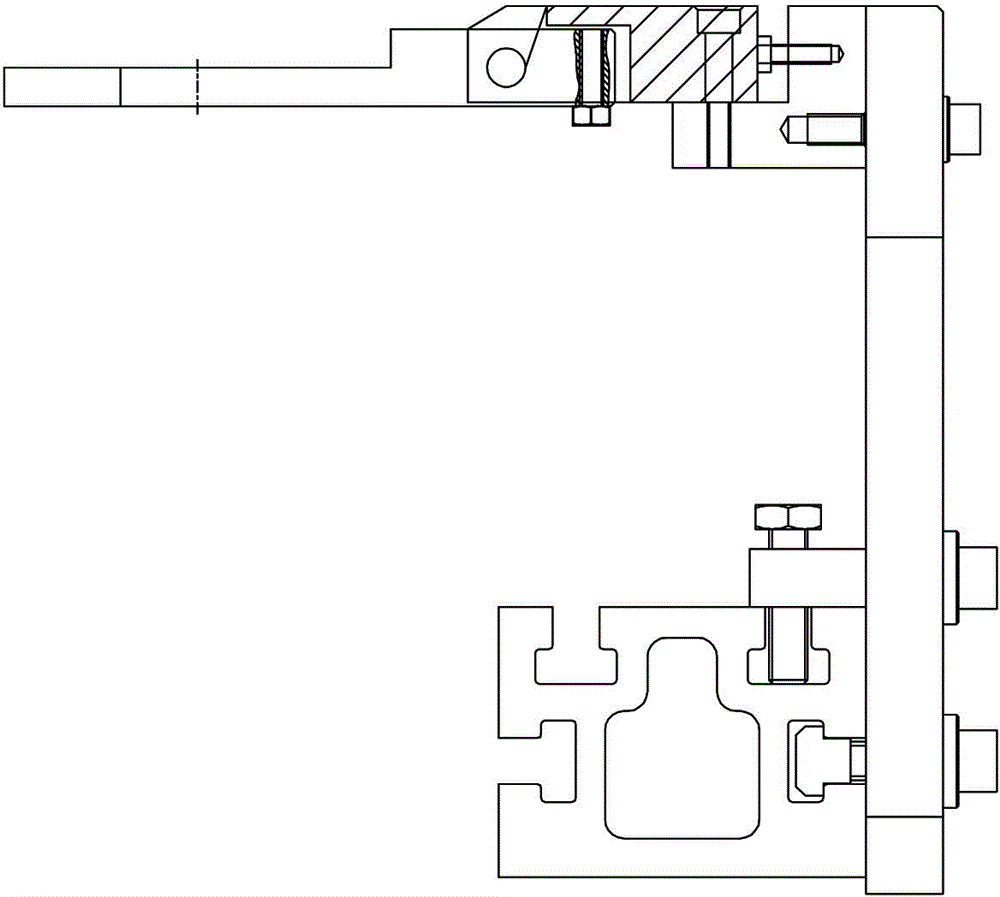

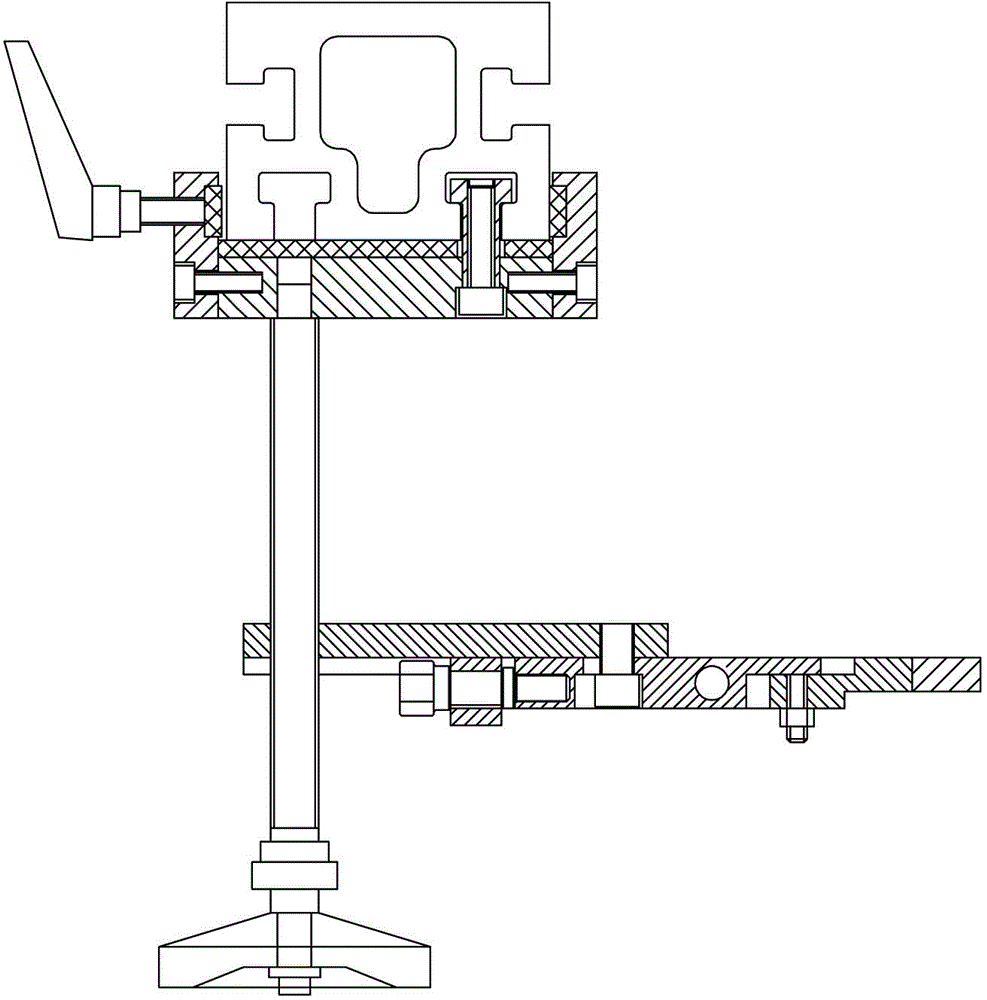

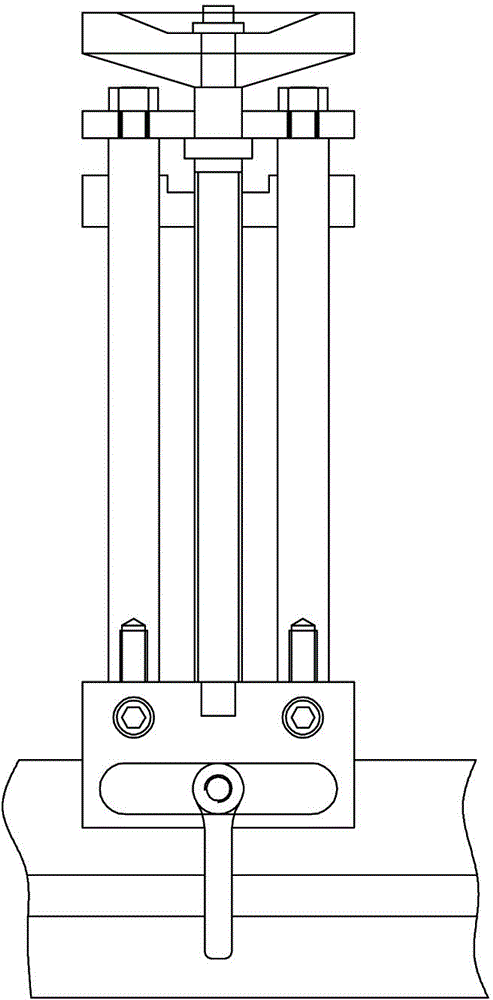

[0016] see Figure 4 , the present invention includes a stopper block, the stopper block is installed on a lifting seat 4, in particular: the lifting seat 4 is provided with two front and rear through holes, and a nut 5 is fixed in the front through hole to fit a transmission wire Rod 6, the rear through hole is mounted on a vertical guide column 10, and the upper and lower ends of the guide column 10 are respectively fixed with a top plate 7 and a base 15, and the top plate 7 is provided with the front through hole on the lifting seat 4. The shaft holes arranged coaxially, the shaft holes support the upper end of the transmission screw rod 6, and the upper end of the transmission screw rod 6 extends out of the top plate 7, the outer mounting retaining ring 8 and the rotating hand wheel 9.

[0017] In this embodiment, the material stopper is formed by connecting the movable stopper 1 and the fixed stopper 3 with the pin shaft 2 , and the fixed stopper 3 is installed on the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com