Lock bolt for groove

A technology for anti-loosening bolts and bolts, applied in the direction of bolts, screws, nuts, etc., can solve the problems of reduced anti-corrosion ability of nuts, reduced locking performance, and failure, so as to reduce the probability of dry friction and reduce the contact area , The effect of improving the ability of anti-moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

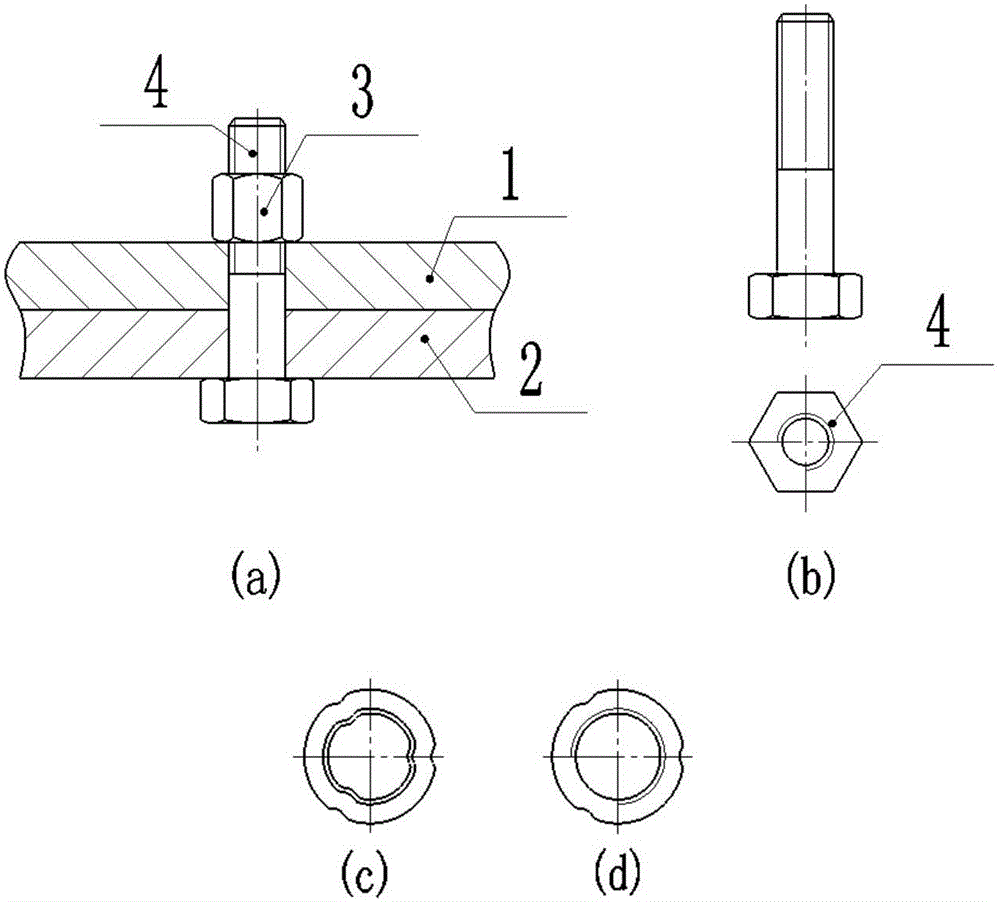

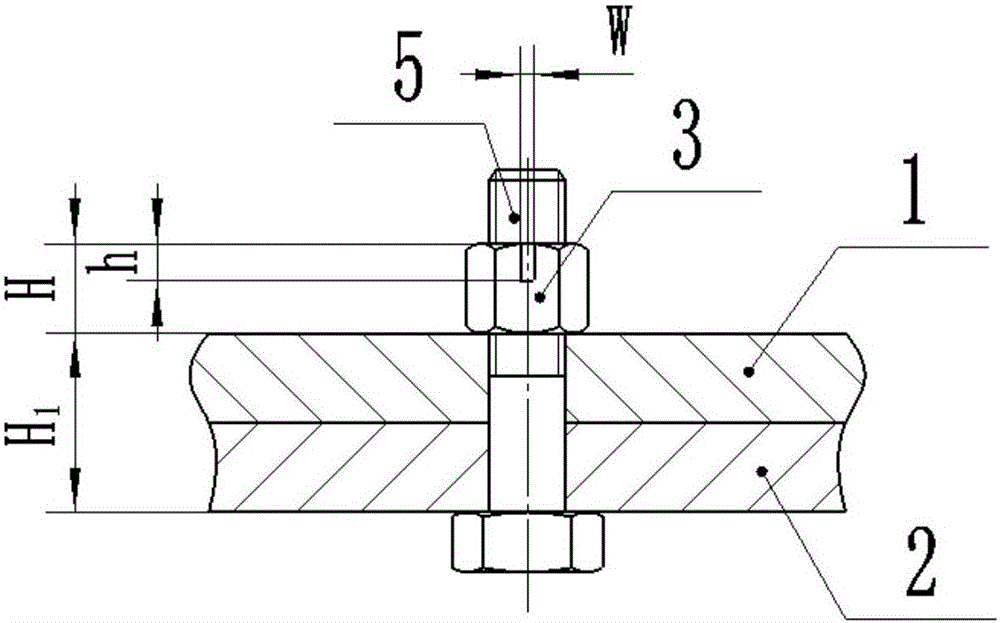

[0032] Technical scheme of the present invention comprises self-locking nut and recessed bolt (as figure 2 (a) shown); the grooved bolt is based on the common bolt and uses a plane parallel to the bolt axis to cut off the tooth height of the bolt external thread part to form a groove, and the tooth height of the cut part is the basic tooth type The height is 2 / 3±5%, retaining the arc of the bolt tooth bottom, so that the bolt tooth bottom and the nut tooth top maintain the spiral guiding function, the groove width W=(1.5~2)×P, where P pitch, the distance between the groove and the bolt The distance of the hexagonal head is: the total thickness of the interlayer H 1 (Including the thickness of the washer) + nut height H - closing height h - (2 ~ 3) × P, and then the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com