Slicing machine with reversing device

一种切片机、枢转的技术,应用在取样装置、测量装置、传动装置等方向,能够解决提高成本、多零部件、增加传动单元复杂性等问题,达到减少构件数量、降低成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

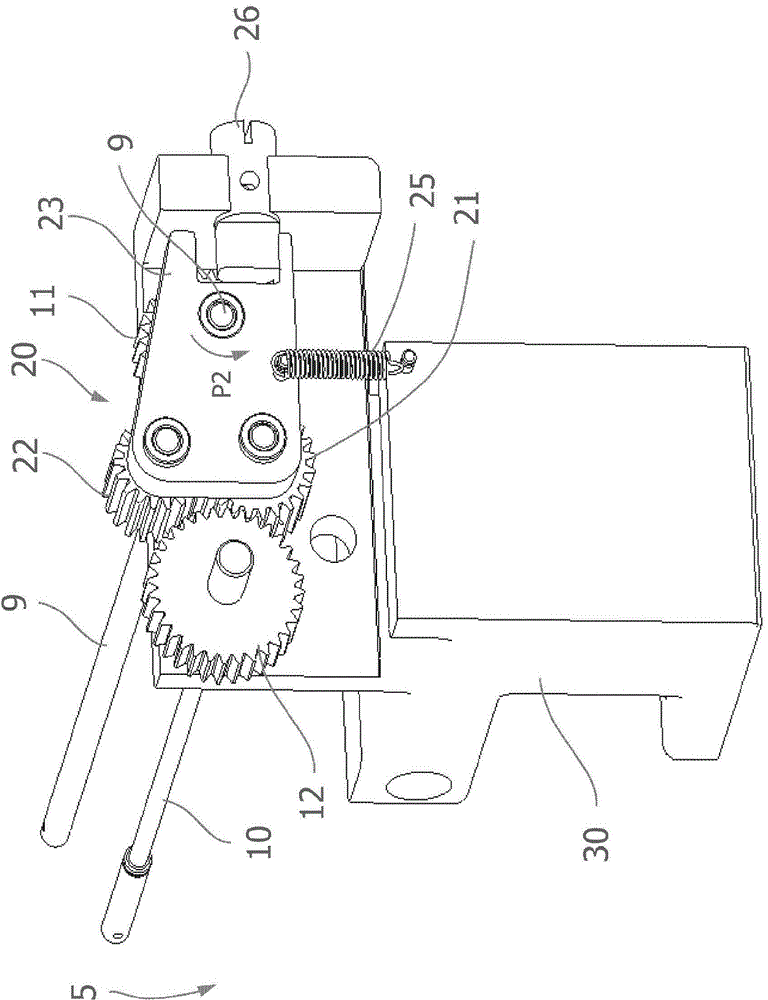

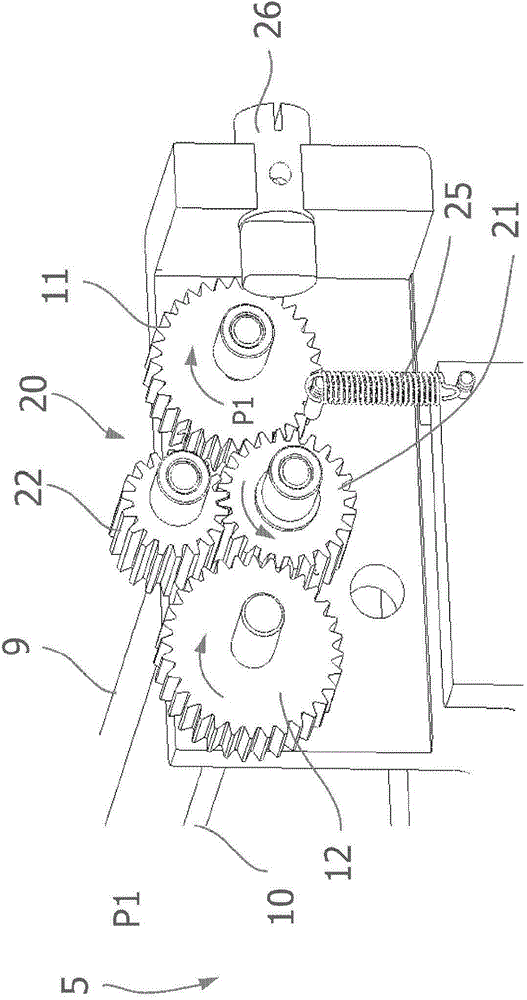

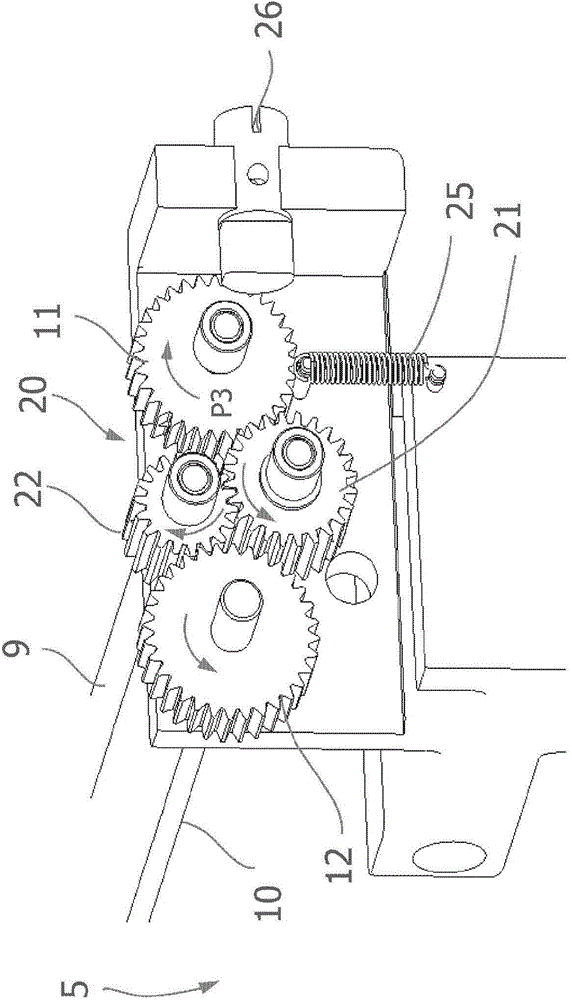

[0025] figure 1 A schematic perspective view of details of the microtome 5 is shown. figure 2 shows the transmission unit in the first position, and image 3 The transmission unit is shown in the second position.

[0026] see figure 1 , the slicer 5 includes a first shaft 9, and a first gear 11 is non-rotatably connected to one end of the first shaft. The first axis 9 can be figure 1 - The hand wheel not shown in 3 is directly or indirectly driven. The handwheel may be a handwheel for rough infeed of the sample.

[0027] In addition, the microtome 5 comprises a second shaft 10, at one end of which a second gear 12 is non-rotatably connected. Thus, the second axis 10 is used to perform a rough feed and / or to generate a cutting movement. The cutting unit is figure 1 -3 is not shown. The first and second shafts 9, 10 are mounted in the frame 30 by bearing units (not shown). The first and second shafts 9 , 10 and the first and second gear wheels 11 , 12 mounted thereon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com