Multilayer rubber roller

A rubber roller, multi-layer technology, applied in the field of rubber rollers, can solve the problems of poor friction resistance and short service life, and achieve the effects of long service life, improved service life and increased friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

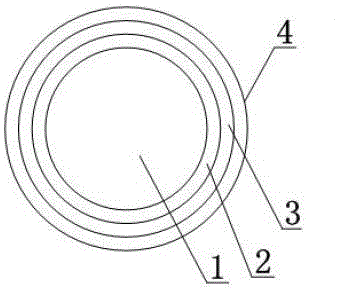

[0013] Such as figure 1 Shown, a kind of multilayer rubber roller, comprises the steel roller 1 that is made of stainless steel material, and the outer surface of steel roller 1 is provided with the first elastic layer 2 that is made by elastic rubber material, and the first elastic layer 2 The thickness is 3cm ~ 5cm, the outer surface of the first elastic layer 2 is provided with the second elastic layer 3 made of elastic rubber material, the thickness of the second elastic layer 3 is 0.5cm ~ 1cm, the outer surface of the second elastic layer 3 There is a ceramic layer 4 on the surface, the thickness of the ceramic layer 4 is 0.3mm~0.5mm, the cross section of the steel roller 1 is circular, the ceramic layer 4 is provided with lines, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com