Buffering structure of precise punching die

A technology of precision stamping dies and buffer structures, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of large force between the upper die and the working limit block, easy damage to the upper die and the lower die, etc. Simple structure, long service life, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

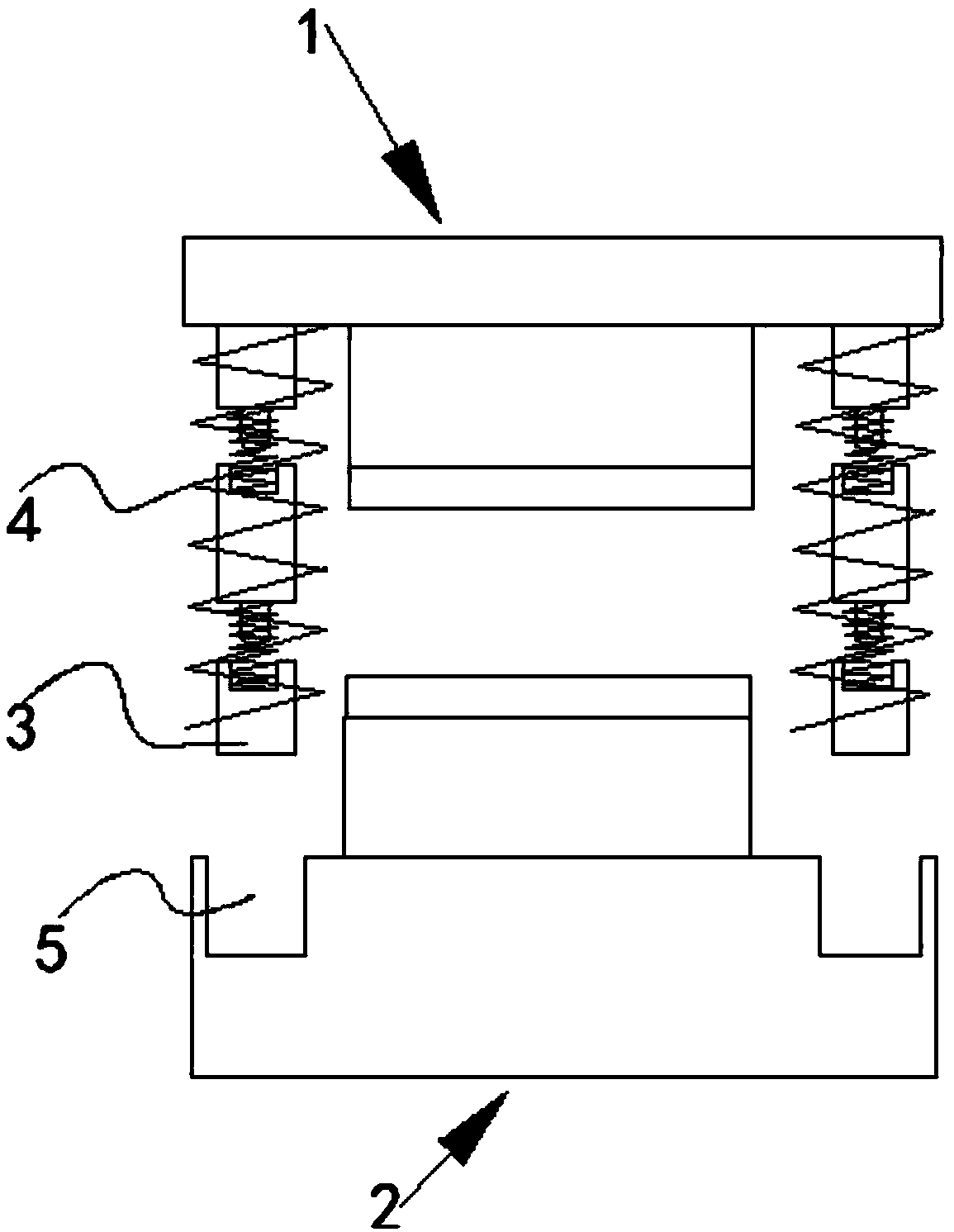

[0024] Embodiment: a buffer structure of precision stamping die, such as Figure 1-Figure 4 As shown, the stamping die comprises an upper die 1 and a lower die 2, the lower end of the upper die is provided with guide posts 3, and the guide posts are provided with four and are respectively located at four corners of the lower end of the upper die. , the outer circumference of the guide column is provided with a first spring 4, and the first spring is fixedly connected with the upper mold; the upper end of the lower mold is provided with four guide holes 5 that cooperate with the guide column;

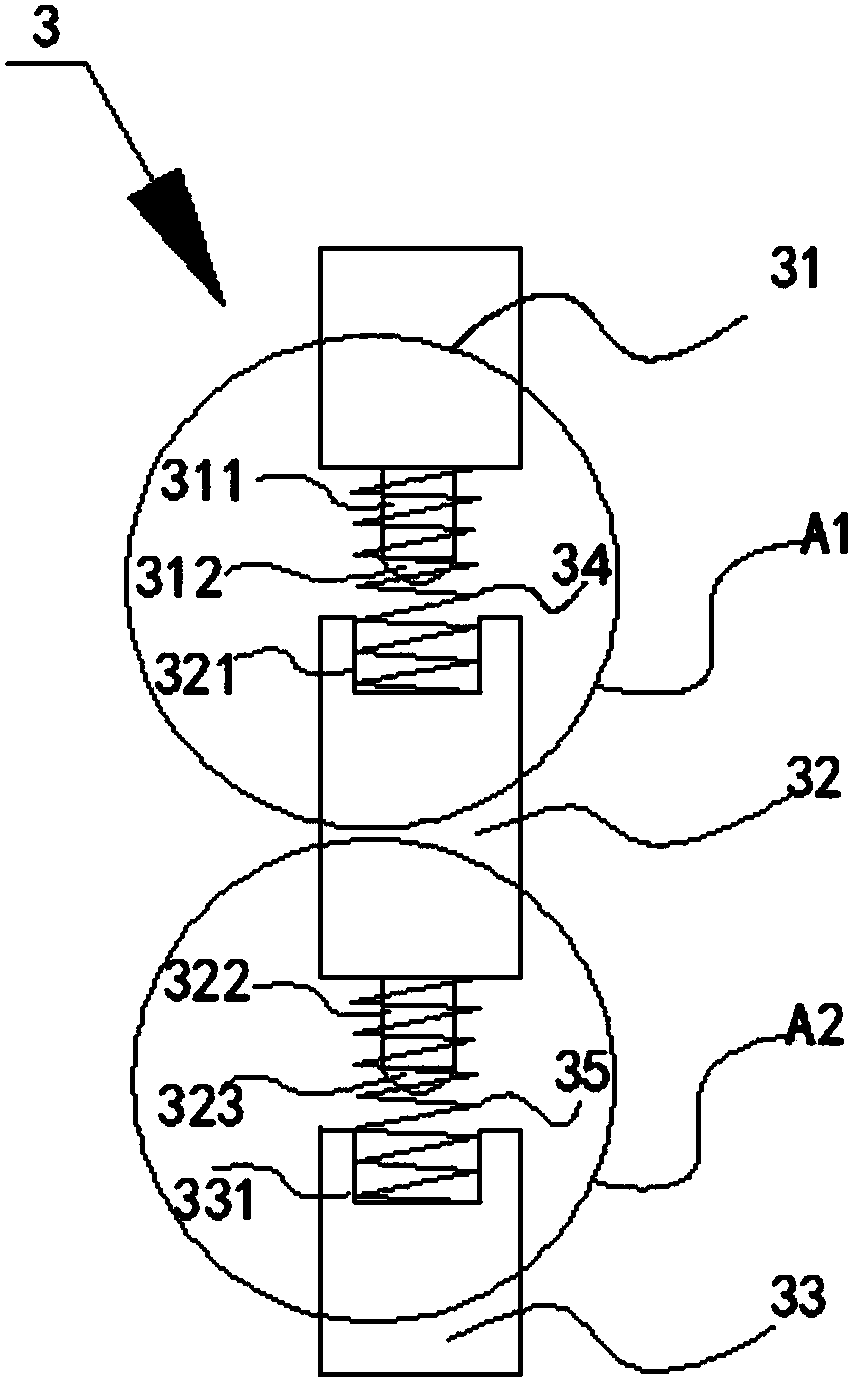

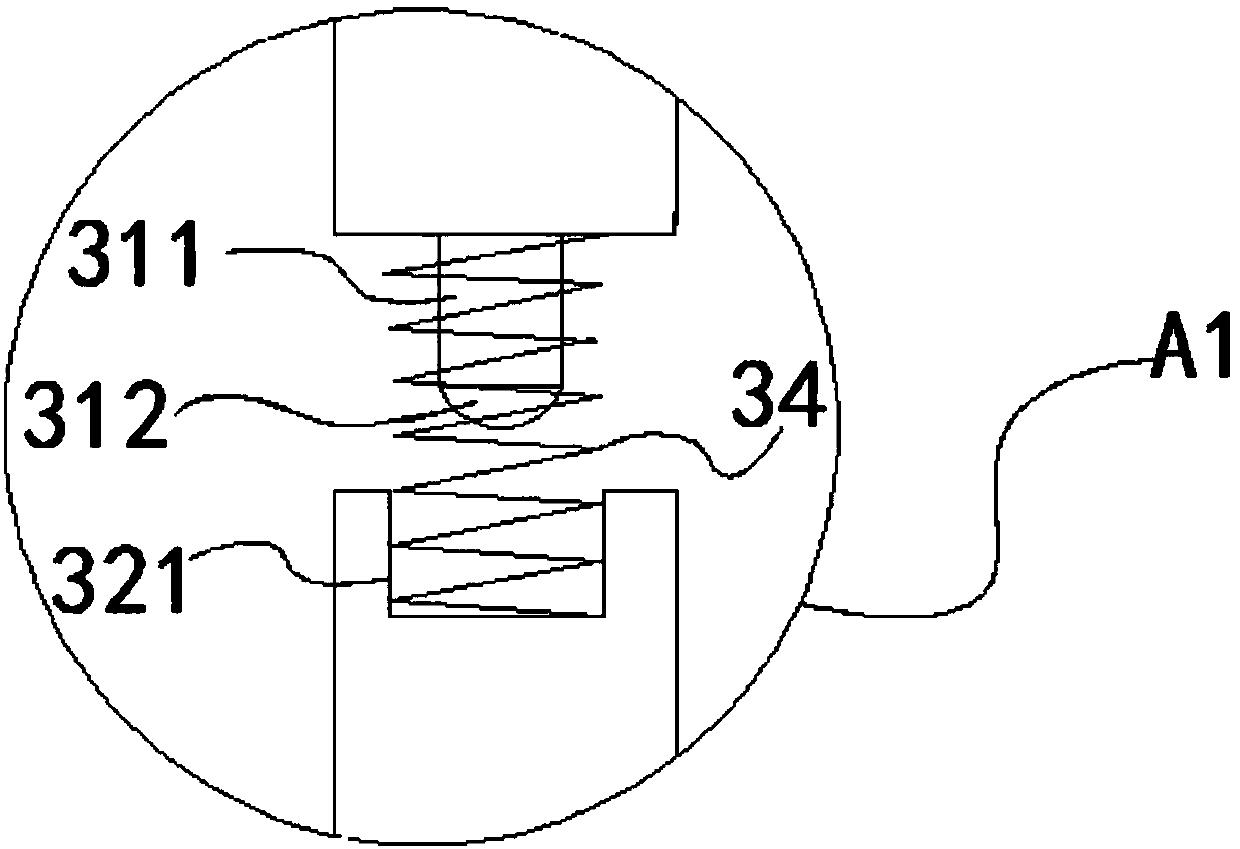

[0025] Each of the guide columns includes a first section guide column 31 at the top, a second section guide column 32 in the middle and a third section guide column 33 below, the first section guide column and the second section guide column The guide posts are connected by a second spring 34, the second section guide posts are connected with the third section guide posts by a third spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com