Food container and manufacturing method thereof

A manufacturing method and container technology, which is applied to food heating containers, containers, and packaged foods, etc., can solve problems affecting food quality, container combustion, etc., and achieve increased integration strength, less high temperature, and a stable integrated state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

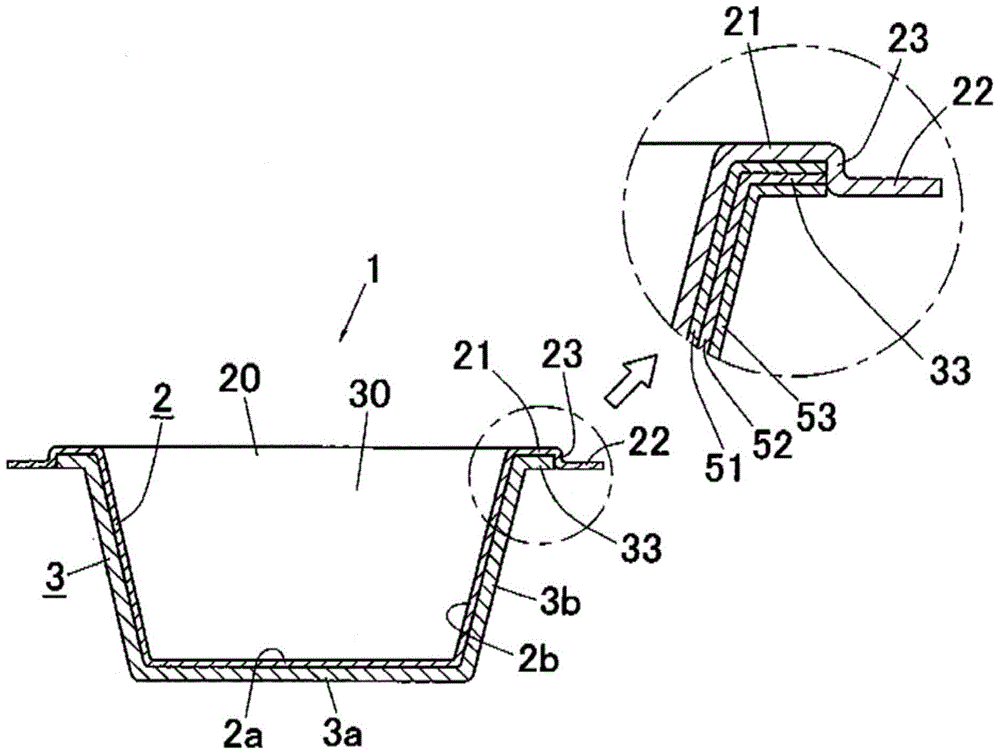

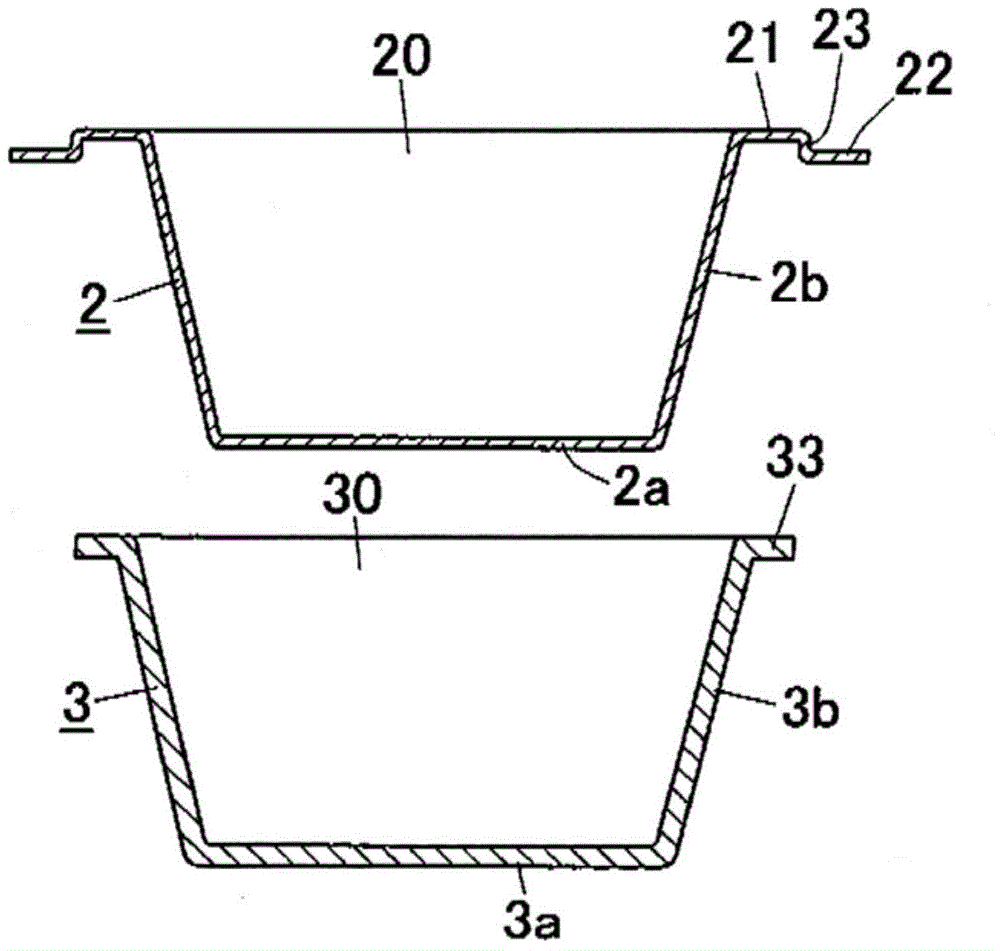

[0182] Manufactured by the "manufacturing method using injection molding" explained in the preceding paragraph figure 1 Shown is a container 1 for food. The outer container 3 is an outer container with a thickness of 120 μm formed by using aluminum (A8021-O material), and the molten polypropylene resin heated to 230°C is injected into the cavity for molding, thereby injecting the molten resin into the outer container 3 The outer surface of the inner container 2 with a thickness of 1.0 mm is overlapped with the outer container 3 with a thickness of 120 μm, and the two containers 2 and 3 are tightly integrated and can be separated. Container 1 for food.

Embodiment 2

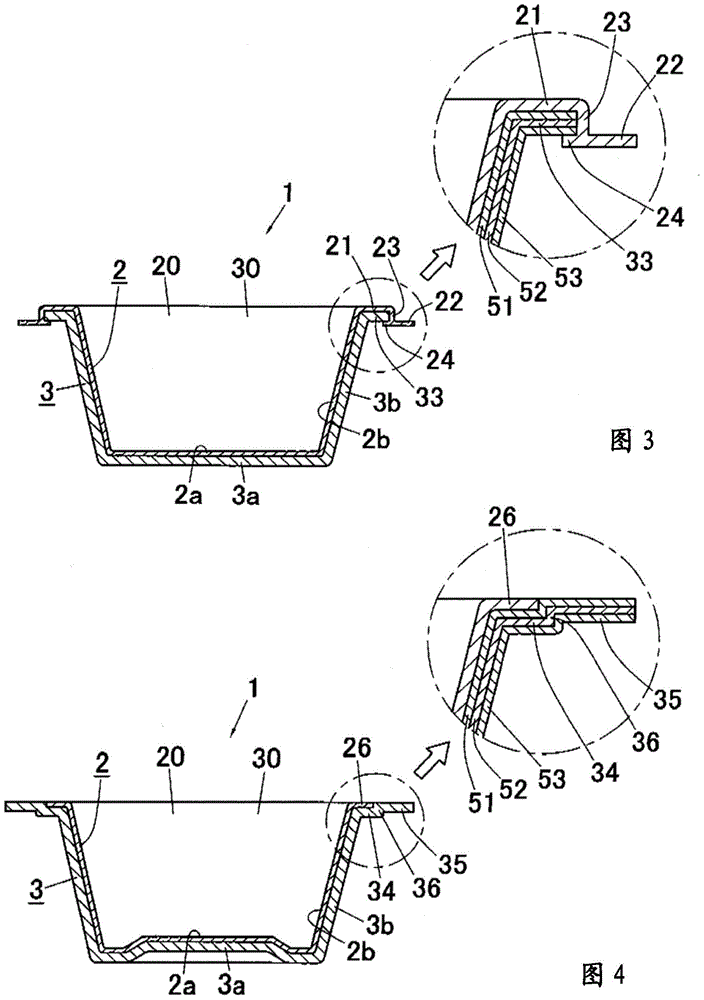

[0186] Manufactured by the "manufacturing method using pressure forming" explained in the preceding paragraph image 3 Shown is a container 1 for food. The outer container 3 is an outer container composed of a three-layer laminate of crystalline polypropylene layer (inner layer) (30 μm) / aluminum layer (120 μm) / crystalline polypropylene layer (outer layer) (200 μm); made of resin The sheet 70 is a polypropylene sheet with a thickness of 1.0 mm, and the resin sheet 70 heated to 145° C. is laminated on the inner surface of the outer container 3 to perform pressure molding to manufacture the inner container 2 with a thickness of 1.0 mm. The outer surface of the food container 1 overlaps the outer container 3 with a thickness of 350 μm, and the two containers 2 and 3 are tightly integrated and can be separated.

Embodiment 3

[0188] As the outer container 3, the outer container was the same as in Example 2, except that an outer container with a three-layer laminate structure of polyethylene layer (inner layer) (30 μm) / aluminum layer (120 μm) / polyethylene layer (outer layer) (200 μm) was used as the outer container 3. way, get image 3 Shown is a container 1 for food.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com