a hanging packer

A suspension packer and packer technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve problems such as long operation period, high risk, and large damage to the inner wall of the upper casing, etc. Achieve the effect of reducing operation time and reducing operation risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

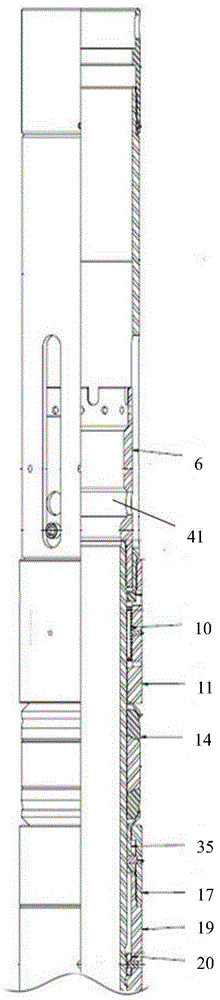

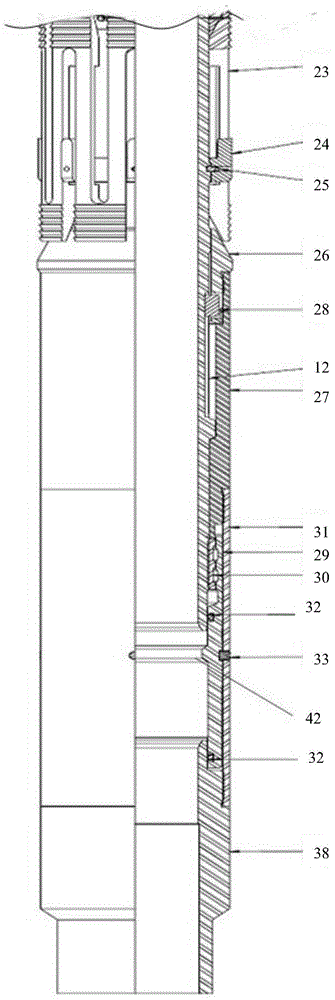

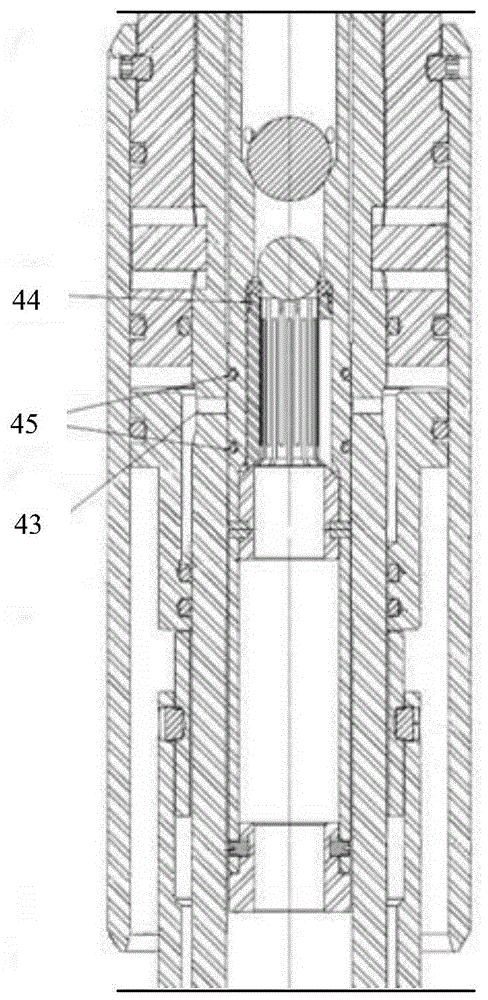

[0024] The suspension packer structure of the preferred embodiment of the present invention is as follows figure 1 and figure 2 shown, see also image 3 , the suspension packer includes a mandrel 12, a top joint 6 is connected above the mandrel 12, a rubber sleeve 14 assembly including a rubber sleeve 14 is connected to the lower end of the top joint 6, and a slip assembly is arranged below the rubber sleeve 14 assembly. An unpacking assembly is arranged under the assembly to facilitate the recovery of the packer; among them, the top joint 6 is provided with the outer layer key on the packer delivery tool to rotate the packer string during the lowering process. A keyway 41; the pressure transmission hole 43 of the packer delivery tool is separated from the packer string by a ball seat and its sealing rubber ring; the unsealing component includes an unsealing sleeve, and the unsealing sleeve is provided with a Cooperate with the key block on the packer recovery tool to lift ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com