Mixer

A kneader and kneading technology, applied in mixers, mechanical equipment, mixers with rotary stirring devices, etc., can solve the problems of inability to maintain the sealing state of the kneader

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

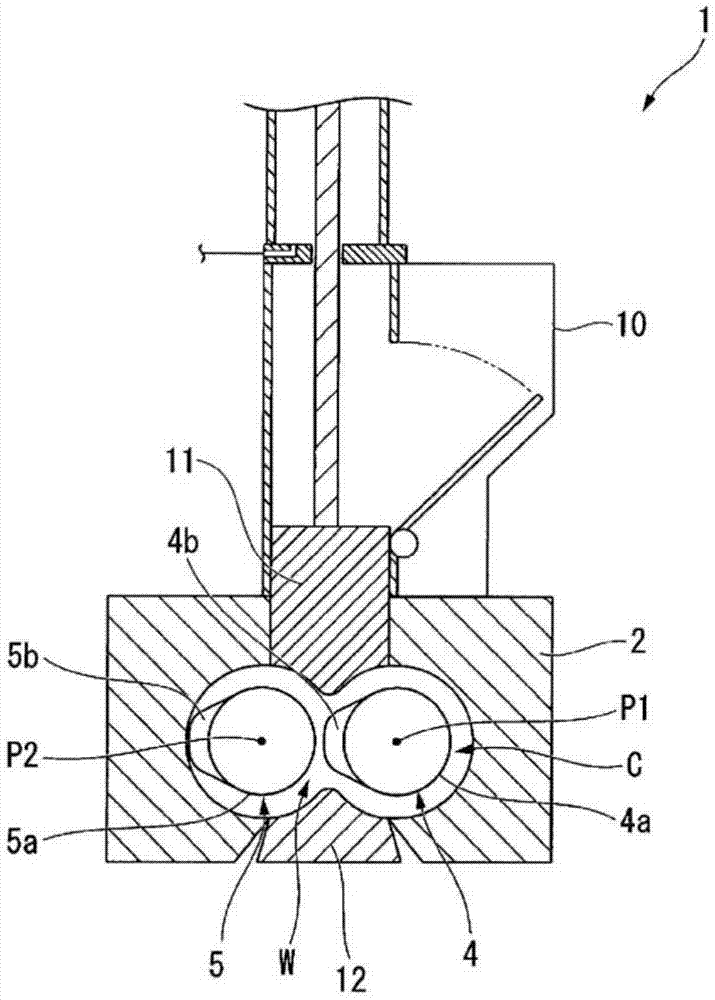

[0038] Next, the kneader 1 according to the embodiment of the present invention will be described.

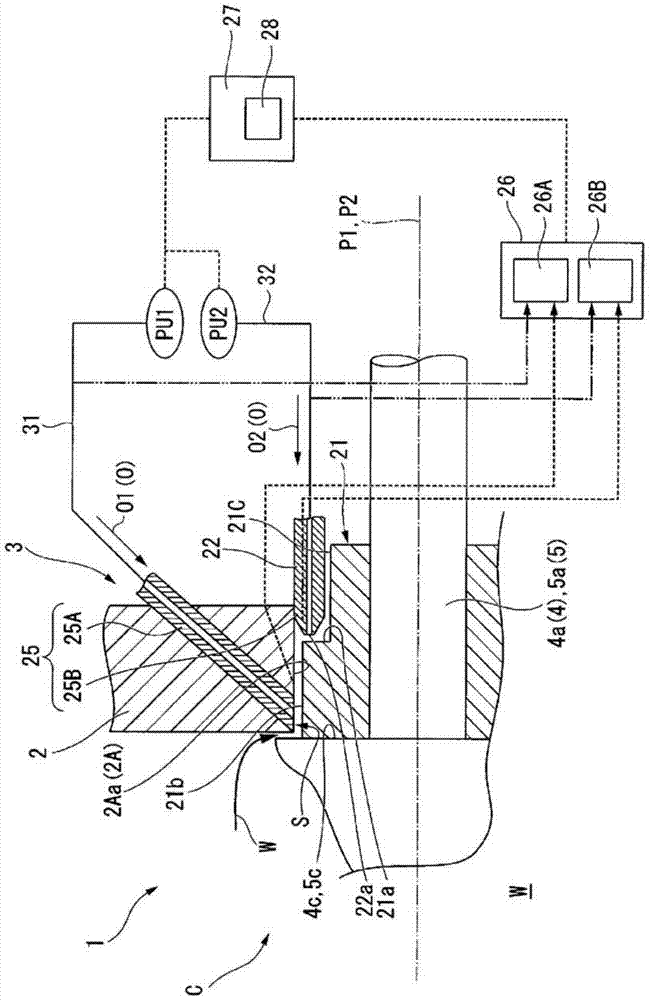

[0039] Such as figure 1 As shown, the kneading machine 1 has: a chamber 2 with a space formed inside, a pair of kneading rotors 4, 5 arranged in this space, and a pair of kneading rotors 4, 5 between the kneading rotors 4, 5 and the chamber 2 Sealing device 3 for sealing the gap (refer to figure 2 ), is the so-called closed mixer.

[0040] The chamber 2 is a member having a space formed therein. And this internal space is a kneading chamber C which kneads the kneaded material W, such as a rubber raw material.

[0041] The upper part of the chamber 2 is provided with a hopper 10 for inputting the kneading material W and a floating weight 11 that can move up and down, and the kneading material W input from the hopper 10 is pressed into the kneading chamber by the descending action of the floating weight 11 C inside.

[0042] Furthermore, a discharge door 12 for opening the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com