Metal assembled body

An assembly and metal technology, applied in metal processing, metal processing equipment, transportation and packaging, etc., can solve the problem that the igniter is difficult to produce gas output, and achieve the effect of inhibiting outflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the form of the metal assembly according to this embodiment will be described with reference to the drawings. In addition, the structure of the following embodiment is an illustration, and the disclosure of this application is not limited to the structure of these embodiment. In addition, each structure in each embodiment, their combination, etc. are an example, and addition, omission, substitution, and other changes of a structure can be suitably made in the range which does not deviate from the gist of this invention. The disclosure in this specification is not limited by the embodiments but only by the claims. Moreover, each solution disclosed in this specification can be combined with any other features disclosed in this specification.

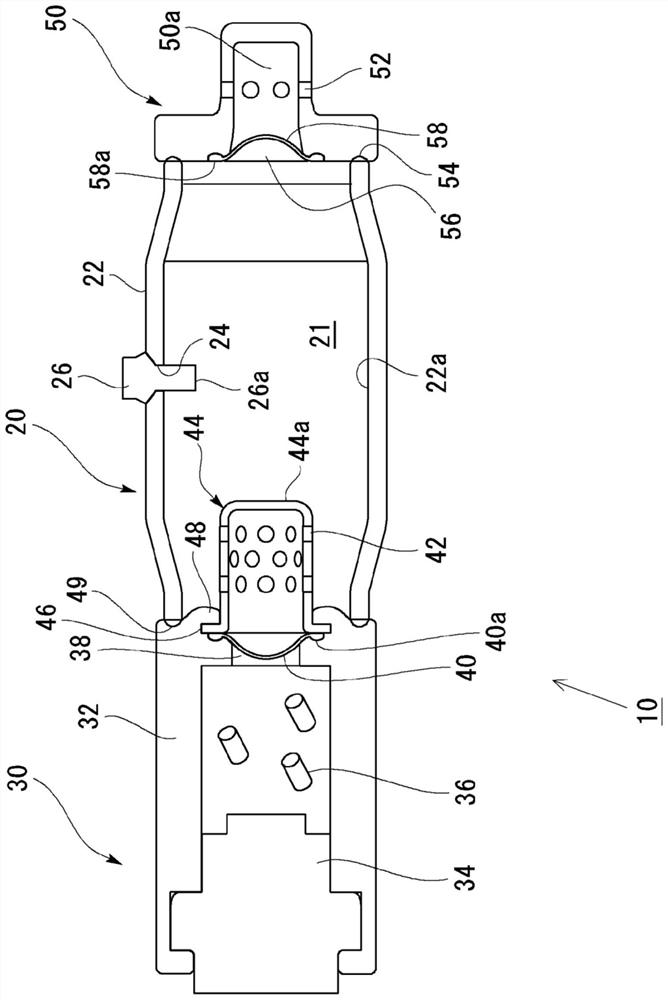

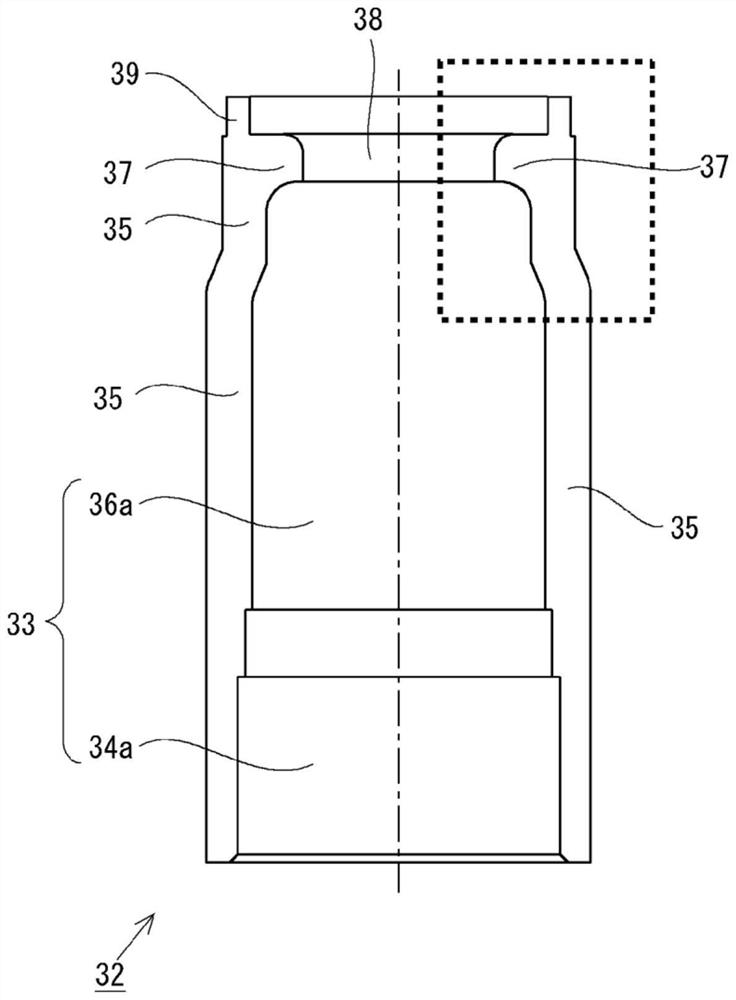

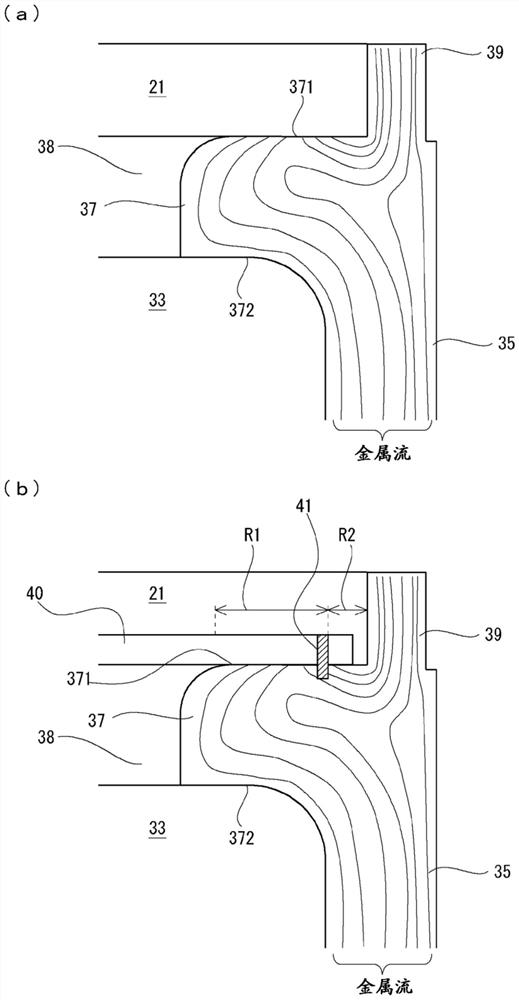

[0032] figure 1 The schematic structure of the inflator 10 comprised including the metal assembly of this embodiment is shown. figure 1 It is an axial sectional view of the inflator 10 . It should be noted that, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com