Garden pruning shear all-in-one machine

An all-in-one machine and branch shearing technology, applied in the field of machinery, can solve problems such as high labor intensity and uneven maintenance of garden vegetation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

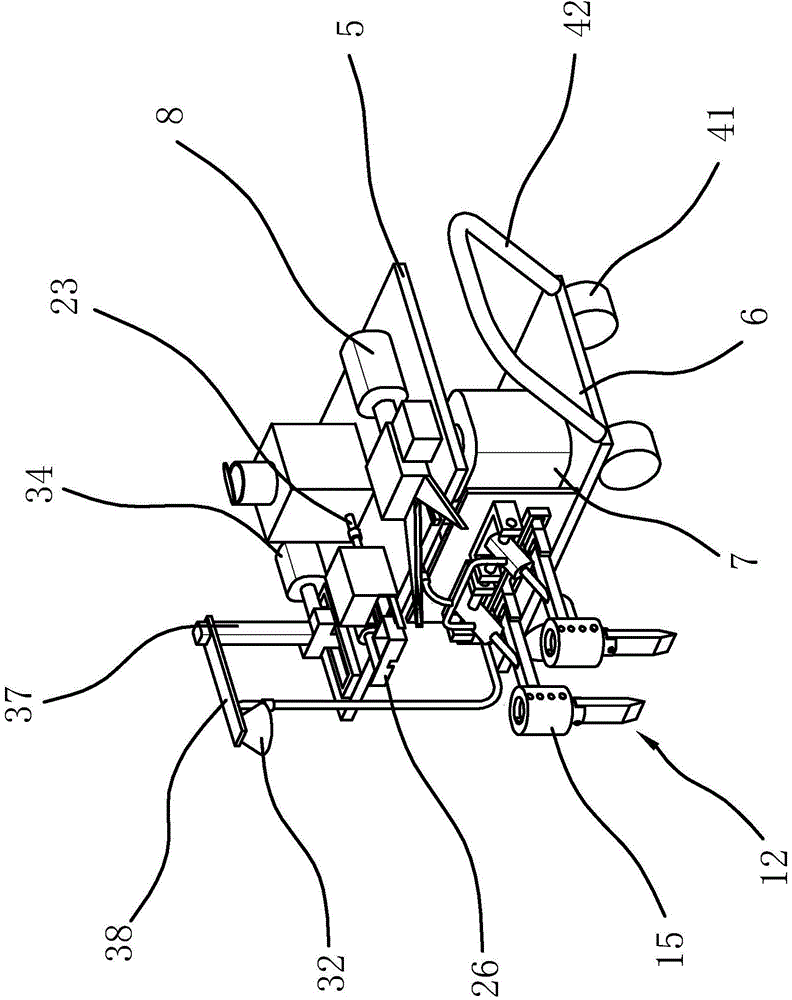

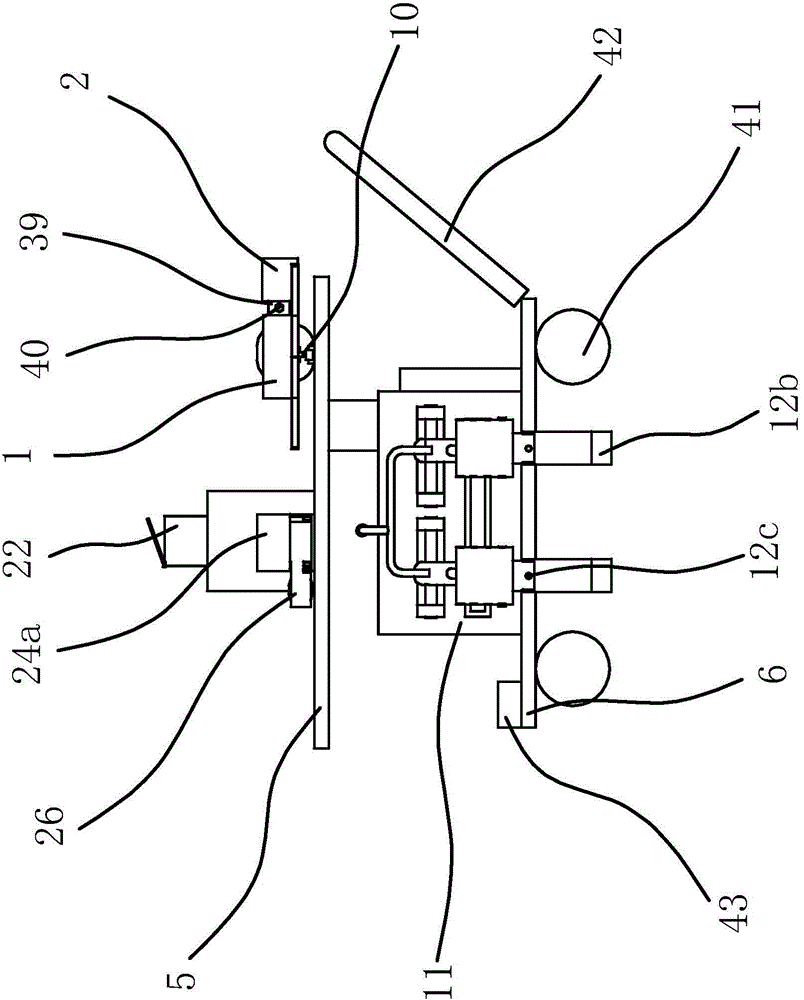

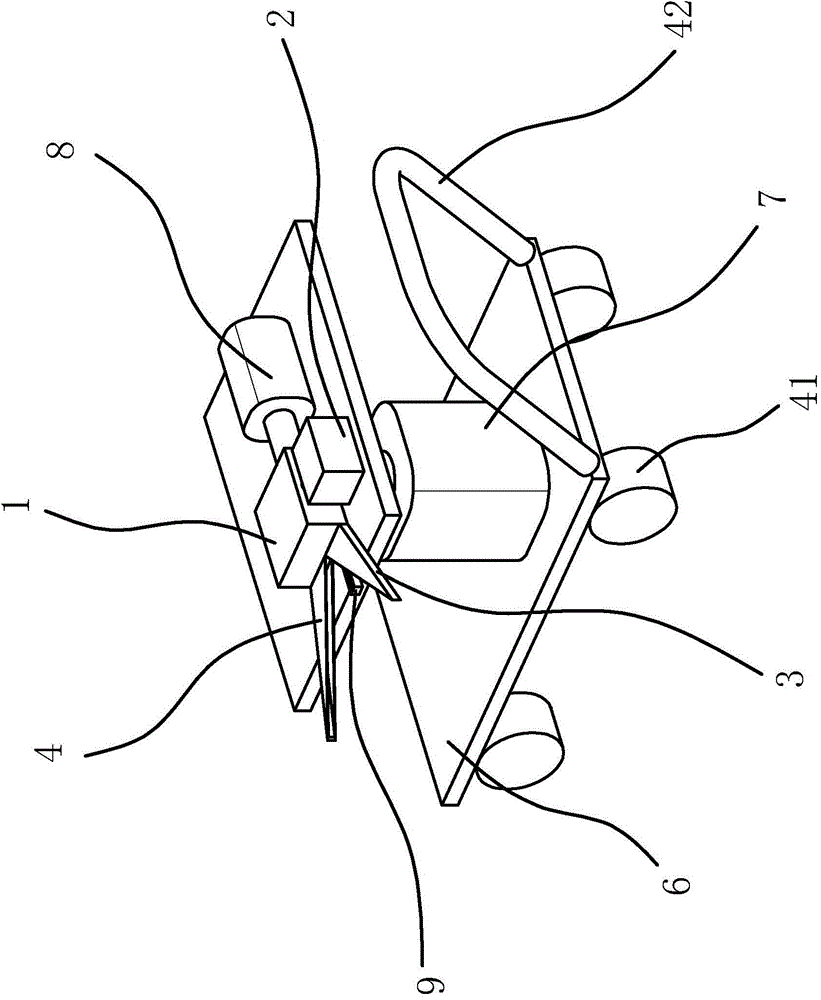

[0037] Such as figure 1 with figure 2 As shown, an all-in-one garden pruning machine includes a body 1 with an inlet and an outlet. A channel is formed between the inlet and the outlet, and a motor is fixed in the channel. Wherein, the entrance is provided with a branch shear blade one 3 and a branch shear blade two 4 for pruning branches, and the branch shear blade one 3 and the branch shear blade two 4 are symmetrically arranged, and the exit is provided with a collection device capable of collecting residual branches and leaves. In addition, the all-in-one garden branch and pruning machine also includes a working board 5 for supporting the machine body 1 and a base 6 arranged under the working board 5 and capable of supporting the working board 5 . The bottom of the base 6 is provided with traveling wheels 41 . At the same time, the side of the base 6 is hinged with a handrail 42, which makes it easier to apply force through the handrail 42, thereby driving the entire g...

Embodiment 2

[0051] The structure and principle of this embodiment are basically the same as the first embodiment, the difference is that in the first embodiment, the telescopic mechanism includes a telescopic cylinder 25; and in the second embodiment, the telescopic mechanism includes a stepping motor, an eccentric wheel and connecting rod 12c. Wherein, the stepping motor is fixed on the working plate 5, and the eccentric wheel is fixed on the output shaft of the stepping motor. One side of the outer end of the fertilization box 24b is fixed with a connecting block 26, one end of the connecting rod 12c is hinged on the connecting block 26, and the other end of the connecting rod 12c is hinged on the eccentric wheel. The stepping motor drives the eccentric wheel to rotate, and through the connecting rod 12c, it drives the fertilization box 24b to perform telescopic movement, so as to fertilize the soil.

Embodiment 3

[0053] The structure and principle of this embodiment are basically the same as the first embodiment, the difference is: in the first embodiment, the sliding mechanism includes a push cylinder 34 and a sliding rail 35 fixed on the working plate 5; and in the second embodiment Among them, the sliding mechanism includes a push rod motor fixed on the working plate 5 and a sliding slot provided on the working plate 5 . The sliding groove is opened along the output shaft direction of the push rod motor, and a sliding block 36 is slidably arranged in the sliding groove. A mounting rod 38 is sheathed on the supporting rod 37 , and the spraying head 32 is fixed on the end of the mounting rod 38 . The push rod motor pushes the slide block 36 to slide on the slide groove, thereby adjusting the spraying head 32 to a position more favorable for spraying the vegetation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com