Multifunctional forage harvester

A harvester, multi-functional technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of reducing the harvesting efficiency of large forage harvesters, increasing the labor intensity of farmers, and increasing planting costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

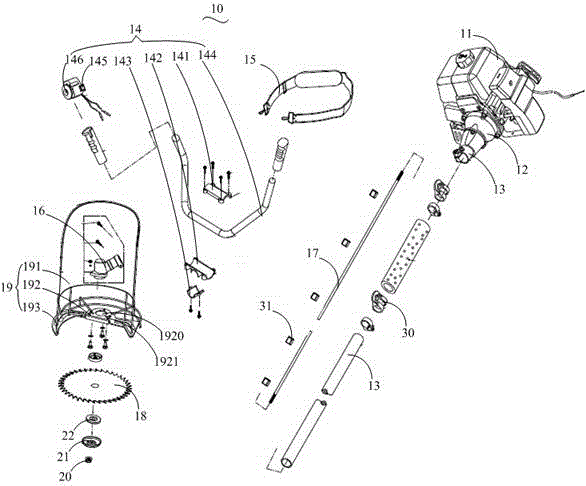

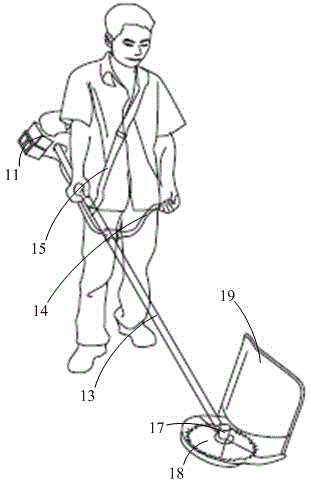

[0009] Such as figure 1 and figure 2 As shown, the multifunctional pasture harvester 10 includes a gasoline engine 11, a clutch disc assembly 12, an aluminum pipe 13, a handle assembly 14, a strap 15, a gear box 16, a transmission shaft 17, a cutter 18 and a grass guiding mechanism 19.

[0010] One end of the aluminum tube 13 is fixedly connected with the gasoline engine 11 and the clutch disc assembly 12, the other end of the aluminum tube 13 is fixedly connected with the gear box 16, and the gear box 16 is also fixedly connected with the grass guiding mechanism 19, and the transmission shaft 17 is arranged on the aluminum tube 13 In the pipeline, and one end of the transmission shaft 17 is fixedly connected with the output end of the gasoline engine 11 through the clutch disc assembly 12, the other end of the transmission shaft 17 is fixedly connected with the input end of the gearbox 16, and the cutter 18 is fixed at the output of the gearbox 16. At the end, the grass gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com