Down coat with fabric capable of preventing leak and stacking of down and dirt

A technology of anti-fouling fabrics and down jackets, which is applied in clothing, clothing, protective clothing, etc., can solve the problems of down piled up, down drilled out, affecting the appearance and comfort of clothing, and achieves the effect of increasing friction and preventing slipping out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

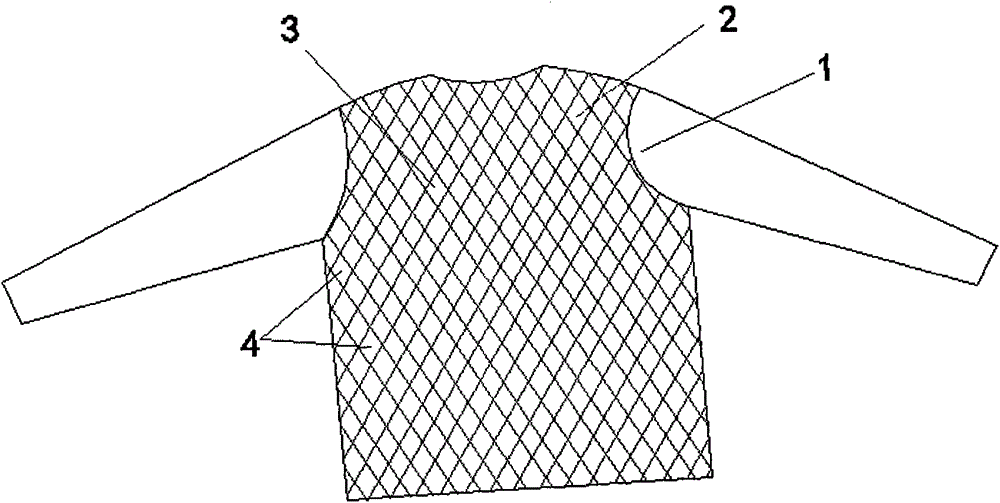

[0014] see figure 1 , an anti-drilling, anti-pile and anti-fouling fabric down jacket of the present invention, comprising a fabric 1, a lining 2 and an inner tank 3, the inner tank 3 is separated into many small diamond-shaped cavities 4 by sewing threads, and the rhombus-shaped cavities 4 are Filled with down, the side of the fabric 1 close to the inner tank 3 is suede-like, and the side of the lining 2 close to the inner tank 3 is suede-like.

[0015] The fabric 1 includes a fabric layer and an antifouling layer. The fabric layer is a planar layer formed by intersecting warp yarns and weft yarns or intertwined warp yarns and weft yarns. The gap formed by the warp yarns and weft yarns is filled with an antifouling layer. The layer is wrapped with an anti-fouling layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com