Comprehensive fire fighting system and comprehensive fire fighting method of large-size oil-containing equipment of transformer substation

A technology of equipment integration and fire protection system, which is applied in fire rescue and other fields, can solve the problems of irreversible damage to transformers, fire protection facilities without automatic actions, and difficulty for personnel to access fire cabinets, etc., to achieve the effect of preventing misoperation and refusal to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

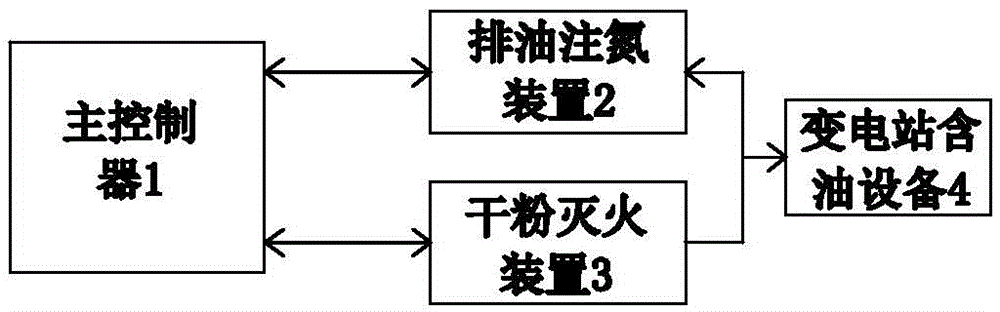

[0029] like figure 1 As shown, the comprehensive fire protection system for large-scale oil-containing equipment in a substation of the present invention includes a main controller 1, an oil discharge nitrogen injection device 2, a dry powder fire extinguishing device 3, and a substation oil-containing equipment 4; the input and output ends of the main controller 1 are respectively connected to the oil discharge The nitrogen injection device 2 and the dry powder fire extinguishing device 3 are connected, and the dry powder fire extinguishing device 3 is set up with the oil discharge nitrogen injection device 2 and the oil-containing equipment 4 of the substation; the oil discharge nitrogen injection device 2 is used for real-time monitoring and collection of state parameters of the transformer and transmission to The main controller 1 receives the corresponding control signal from the main controller 1, and executes corresponding control actions to protect the transformer; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com