Splashing shielding device for spraying

A technology of unwinding device and rewinding device, which is applied in the direction of spraying device to achieve the effect of improving construction efficiency and ensuring bonding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

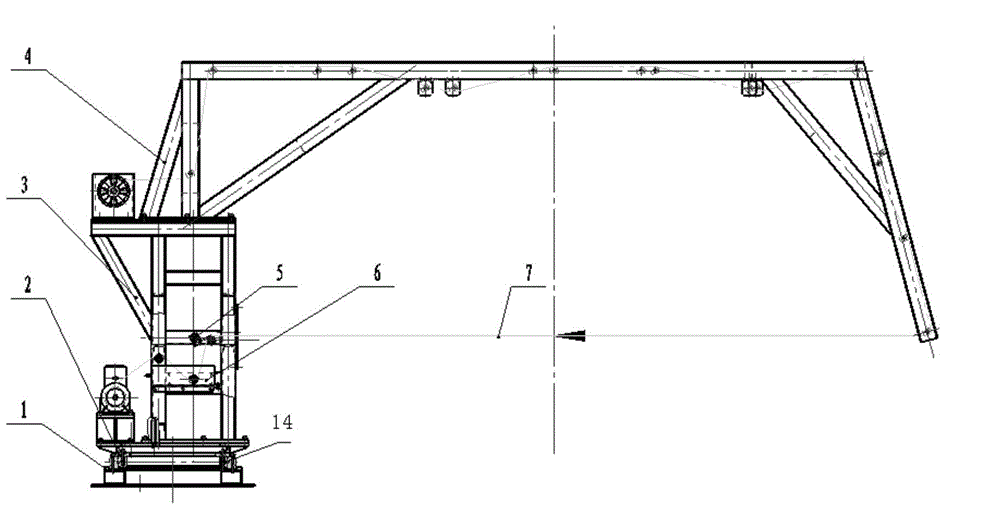

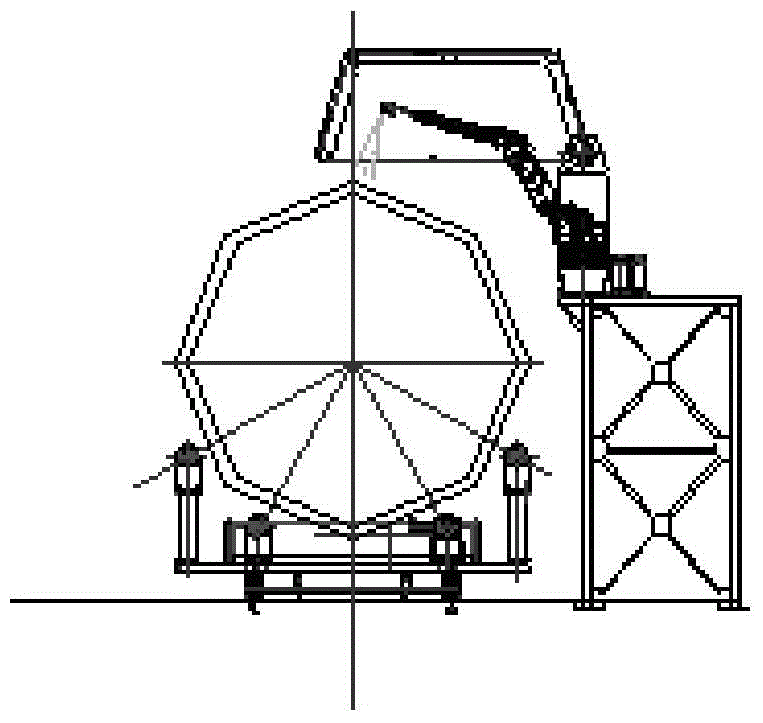

[0019] The spraying splash shielding device is set in the forward direction of the manipulator, and is connected with the manipulator slide plate through the connecting plate. The shielding area of the cloth belt is 1 / 2 of the swing of the manipulator. During the spraying process, the cloth belt cooperates with the action frequency of the manipulator spray gun at a certain speed Transport and clean up in time to realize the shielding of spraying splash materials.

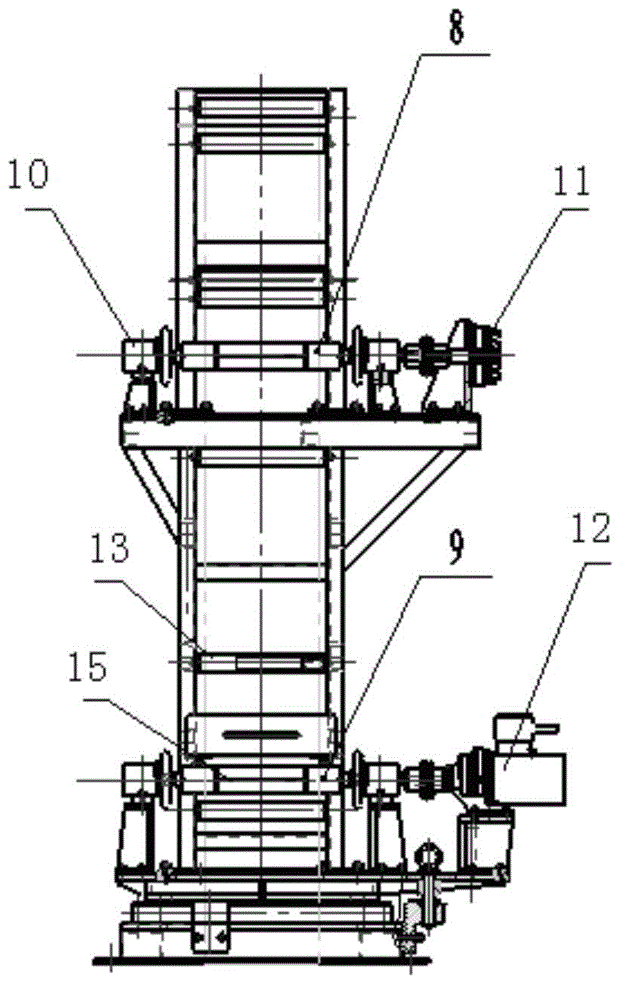

[0020] The device includes a base 1, a rotating disc 2, a frame 3, a bow frame 4, a scraper 5, a cleaning box 6, a cover cloth belt 7, an unwinding device 8, and a winding device 9;

[0021] The rotating disk 2 is placed on the base, and the rotating disk 2 can rotate at least 90 degrees. The rotating disk rotates the bow frame placed on the cantilever 90 degrees to the top of the installation platform o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com