Concrete slab crawler groove formwork and slope concrete construction technology of rockfill dam

A technology for concrete face slabs and rockfill dams, applied in dams, barrages, marine engineering and other directions, can solve the problems of easy deformation and damage of formwork boxes, hidden dangers, unsuitability, etc., and achieve the effects of saving labor, increasing energy consumption, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

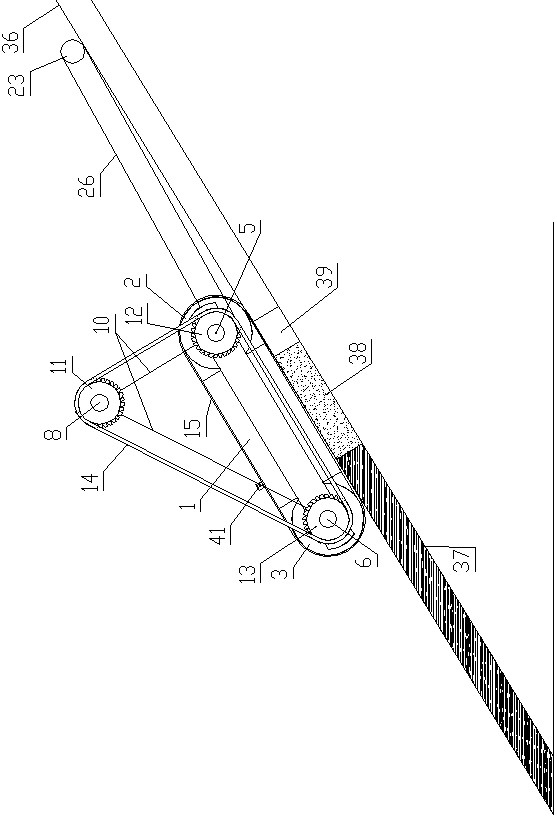

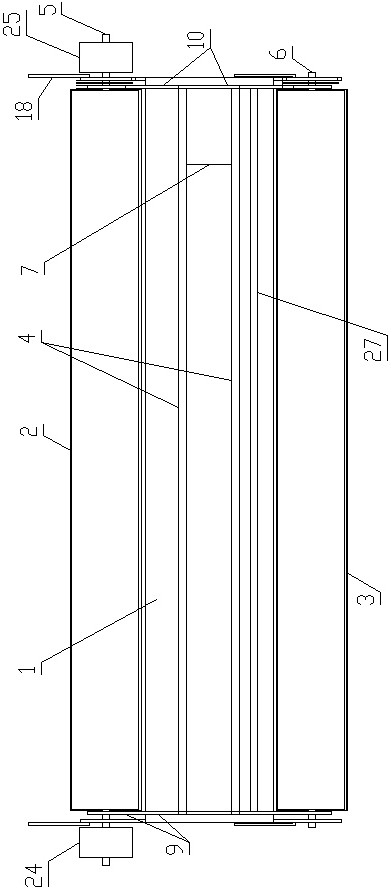

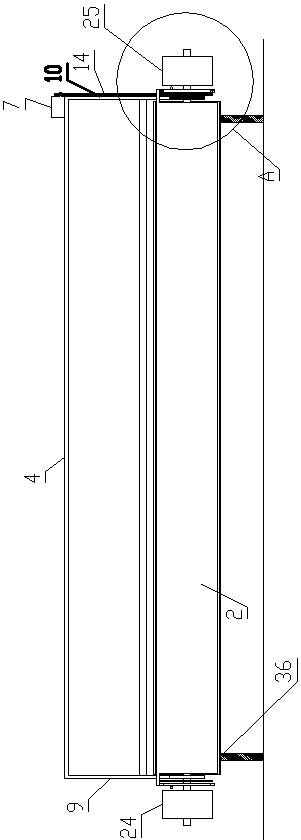

[0065] Such as Figure 1 to Figure 6 As shown, the advancing direction during work, that is, the uphill direction, is forward; the rockfill dam concrete face crawler groove formwork of the present invention includes a cuboid formwork box 1, a front drum 2 arranged in front of the formwork box 1, a The rear drum 3 behind the formwork box 1 and the upper bracket arranged above the front drum 2 ; the upper bracket includes two supporting beams 4 . Figure 4 , the template box is blocked by the rear drum 3.

[0066] The central axis of the front drum 2 is the front shaft 5, the central shaft of the rear drum 3 is the rear shaft 6, and one end of the upper bracket is provided with a forward and reverse drive motor 7, and the output shaft of the forward and reverse drive motor 7 is an upper shaft 8;

[0067] A left support frame 9 is arranged between the left end of the upper bracket, the left end of the front axle 5 and the left end of the rear axle 6, and the left support frame 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com