Heavy-load composite function anchoring device for scaffold

A technology of composite function and anchoring device, which is applied in the direction of scaffolding supported by house structure, house structure support, house structure support, etc., can solve the problems of lack of universal adjustment ability, difficulty in continuous operation, and inability to be put into use immediately. Easy installation, stable support, and the effect of reducing the number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

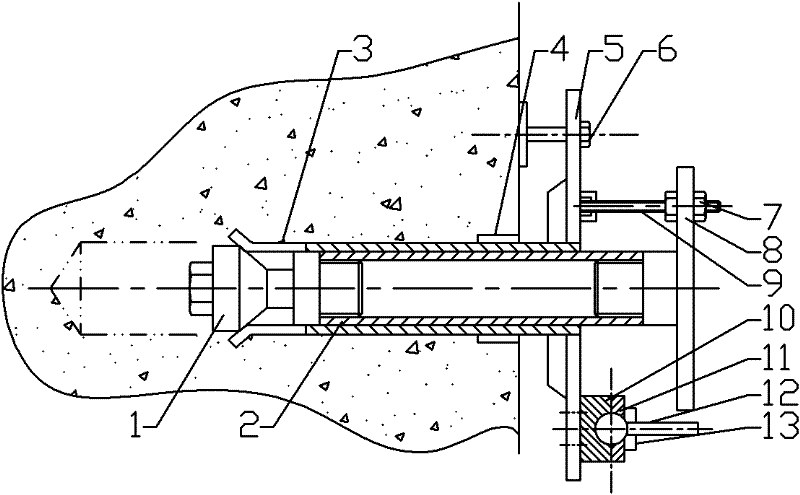

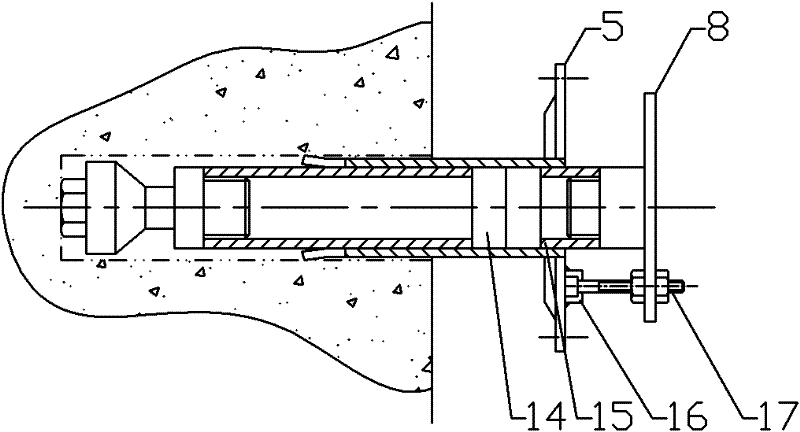

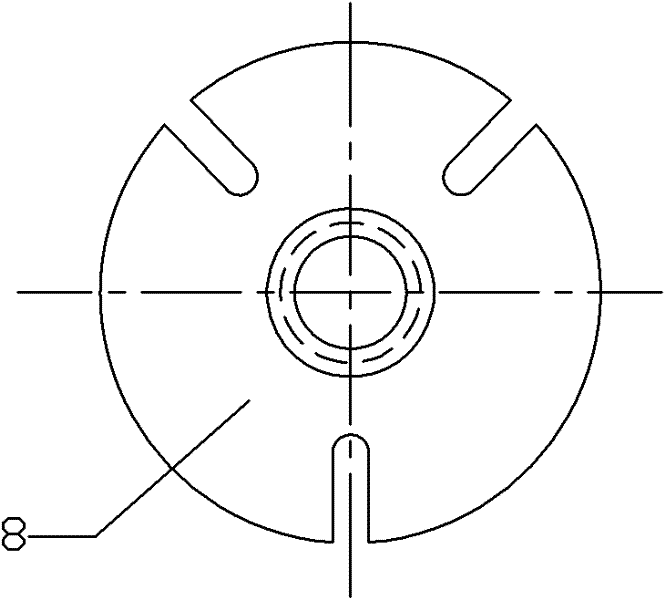

[0014] Refer to attached Figure 1~4 :

[0015] The heavy-duty composite function anchoring device for the scaffold consists of an expansion head 1, an inner tube 2, an outer tube 3, a filling ring 4, an outer tube end plate 5, an anti-loosening bolt 6, a tightening nut 7, and an inner tube end plate 8 , tightening screw 9, turntable base 10, turntable gland 11, turntable shaft 12, turntable stabilizing block 13, dismantling light pad cover 14, dismantling threaded sleeve 15, quick-installing card seat 16 and dismantling screw 17, inner tube 2 Made for heavy-duty seamless pipes, both ends of the pipe body are provided with internal threads, and the upper part is sleeved with an inner pipe end plate 8, and the outer edge of the inner pipe end plate 8 is provided with a plurality of radial short grooves. A tensioning screw 9 and an assembled tensioning nut 7 are installed in the center, the lower part of the inner tube end plate 8 and the upper part of the expansion end 1 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com