Needle aligning mechanism

A light source and prism technology, which is used in the field of needle position detection and correction after the dispenser replaces the needle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

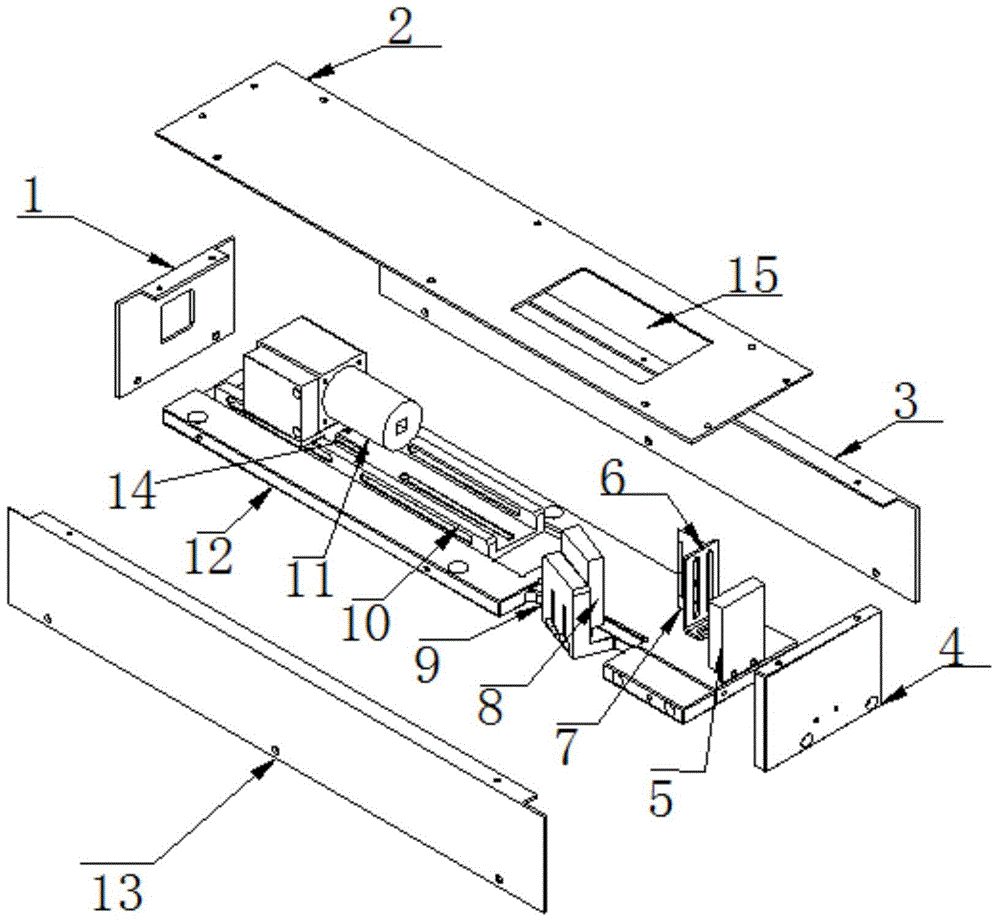

[0024] A needle alignment mechanism, such as figure 1 Shown, comprise base 12 and be placed on the CCD11 of this base, No. 1 light source 5, No. 2 light source 8 and prism 7, take the straight line direction of the lens of CCD as X-axis direction, with the straight line where said CCD lens is perpendicular and The straight line direction parallel to the base is the Z-axis direction, the straight line direction perpendicular to the X-axis direction and the Z-axis direction is the Y-axis direction, the No. 1 light source is set facing the lens of the CCD, and the two The No. 1 light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com