Ultrasonic cleaner

A cleaner and ultrasonic technology, applied in the field of equipment, can solve the problems of high noise, lack of timing function, inconvenience, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

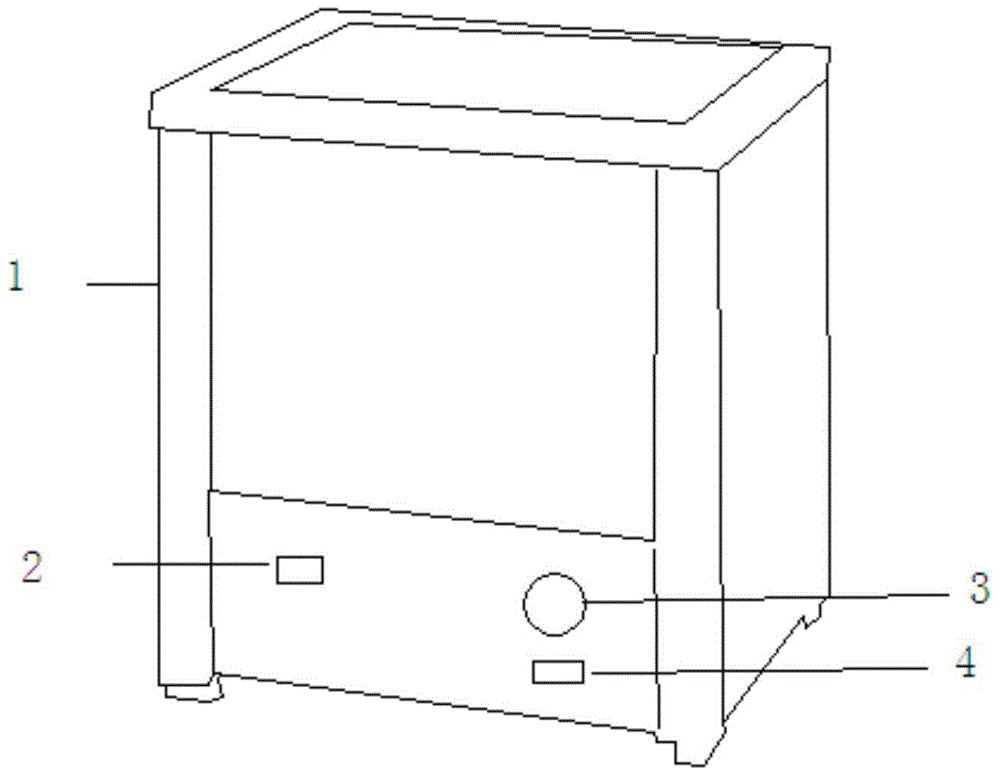

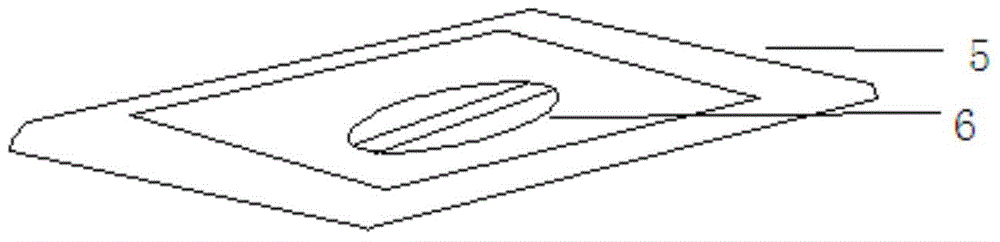

[0018] Such as figure 1 , figure 2 As shown, the present invention relates to an ultrasonic cleaner, comprising an ultrasonic cleaner body 1, the ultrasonic cleaner also includes a cover 5, the cover 5 is made of a viscoelastic heat insulating damping material, and the cover 5 matches the ultrasonic cleaner body 1; A handle 6 is also provided on the cover 5 . In the process of using the ultrasonic cleaner, cover the cover 5. Since the cover 5 is made of viscoelastic heat-insulating damping material, it can reduce the noise of the ultrasonic cleaner and create a quiet atmosphere for people's work. .

[0019] The ultrasonic cleaner body 1 is provided with a timing device 2 . Before using the ultrasonic cleaner, the time required for ultrasound is set, and when the set time is reached, the timing device 2 can automatically stop the ultrasonic cleaner, which is more convenient.

[0020] Preferably, a handle 6 is provided on the cover 5 to facilitate people to take the cover 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com