Wire feeding mechanism of copper strip mill

A technology for rolling mills and copper strips, applied in the field of copper strip rolling mills, can solve problems such as the inability to adjust the line center, various parts specifications, and low production efficiency, and achieve the effects of convenient operation, high production efficiency, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

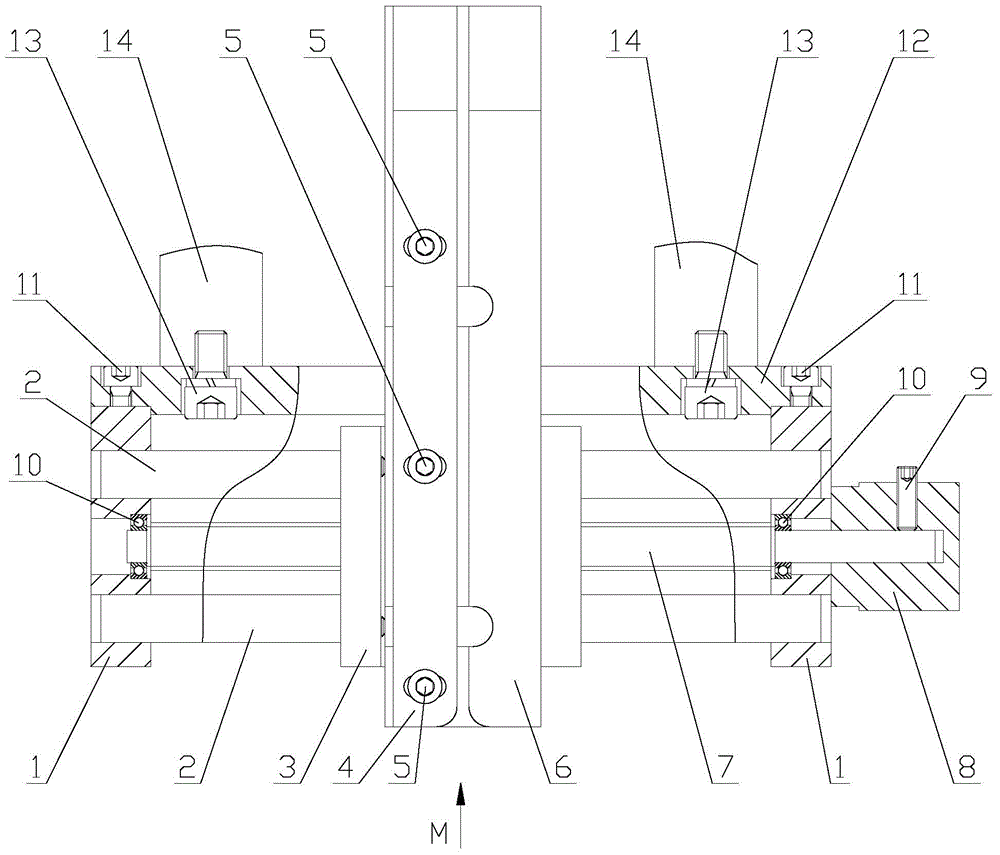

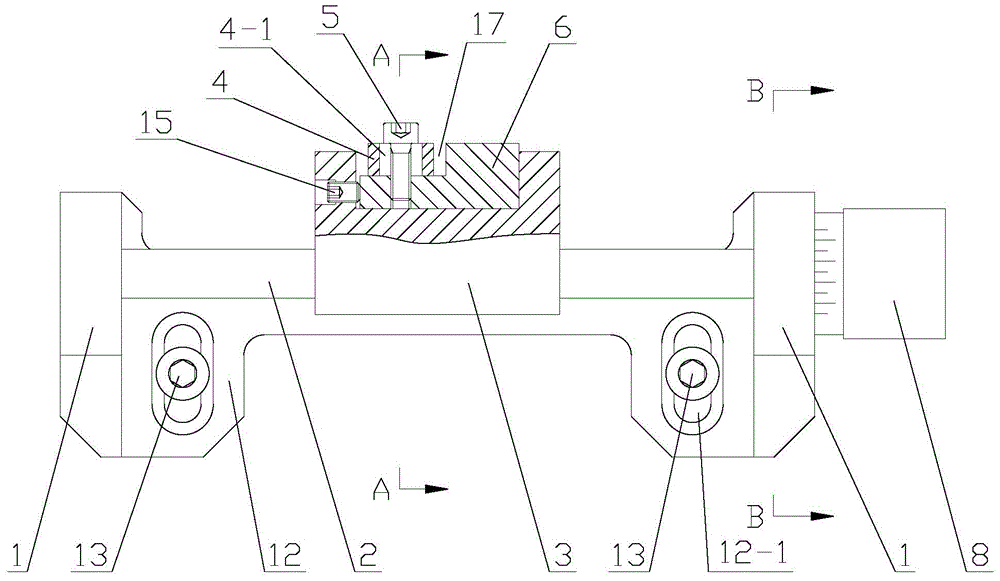

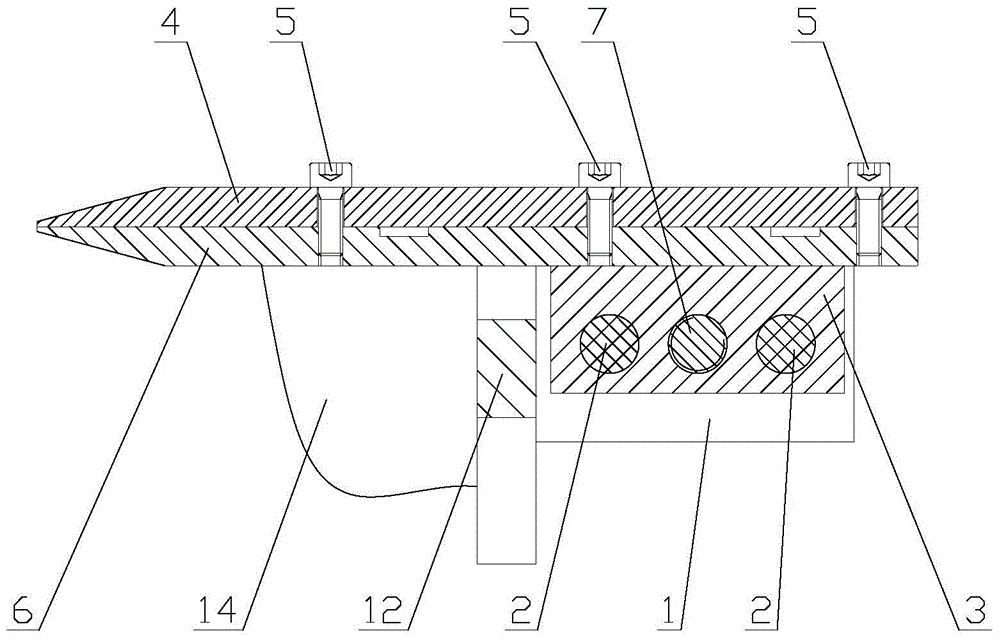

[0031] Such as Figure 1 to Figure 4 As shown, the present invention includes a support plate 1, a connecting plate 12, an adjustment block 3, a guide rod 2 and a screw rod 7, the number of the supporting plates 1 is two and the two supporting plates 1 are symmetrically arranged left and right, and the connecting plate The two ends of 12 are respectively fixedly connected with the front ends of two support plates 1, and the left and right ends of the connecting plate 12 are all provided with oblong holes 12-1, and the number of the guide rods 2 is two and the two guide rods 2 Front and rear are arranged in parallel, the guide rod 2 passes through the adjustment block 3 and the adjustment block 3 can slide left and right along the guide rod 2, the screw rod 7 passes through the adjustment block 3 and is threadedly connected with the adjustment block 3, the guide rod 2 The two ends of the two supporting plates 1 are respectively connected, the screw rod 7 is located between the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap