Valve collet component assembly equipment

A technology for assembling equipment and valve lock clips, which is applied in metal processing equipment, metal processing, manufacturing tools, etc., and can solve problems such as low efficiency and insufficient pressing of lock clips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

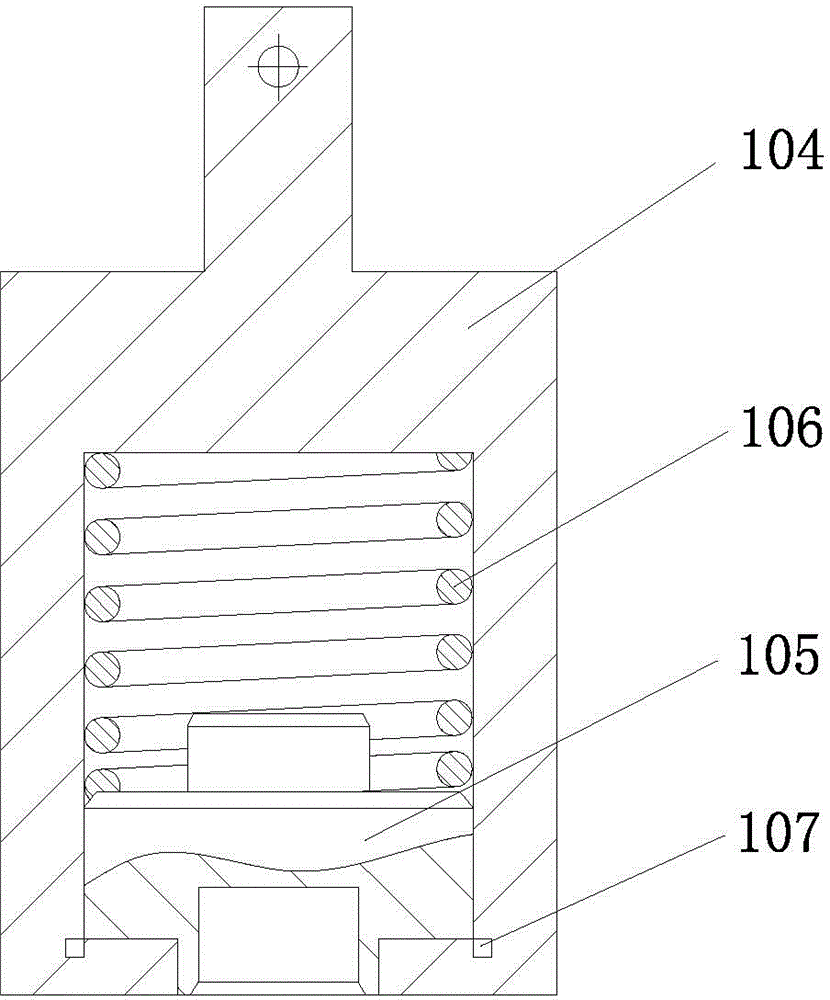

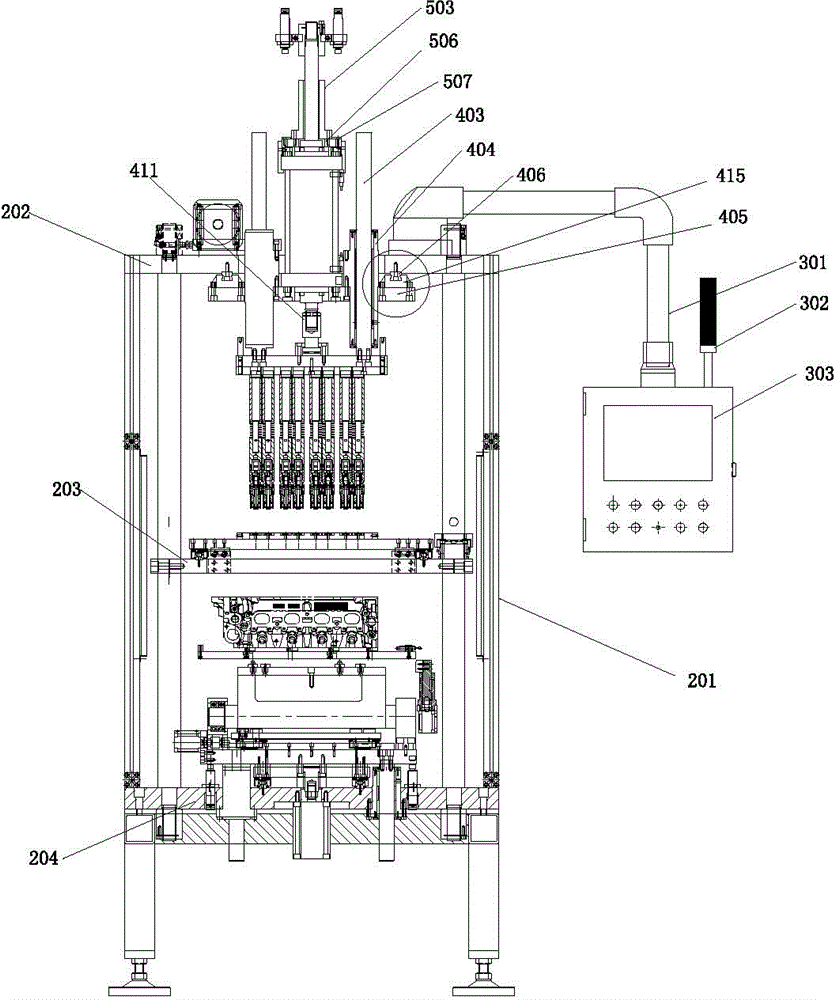

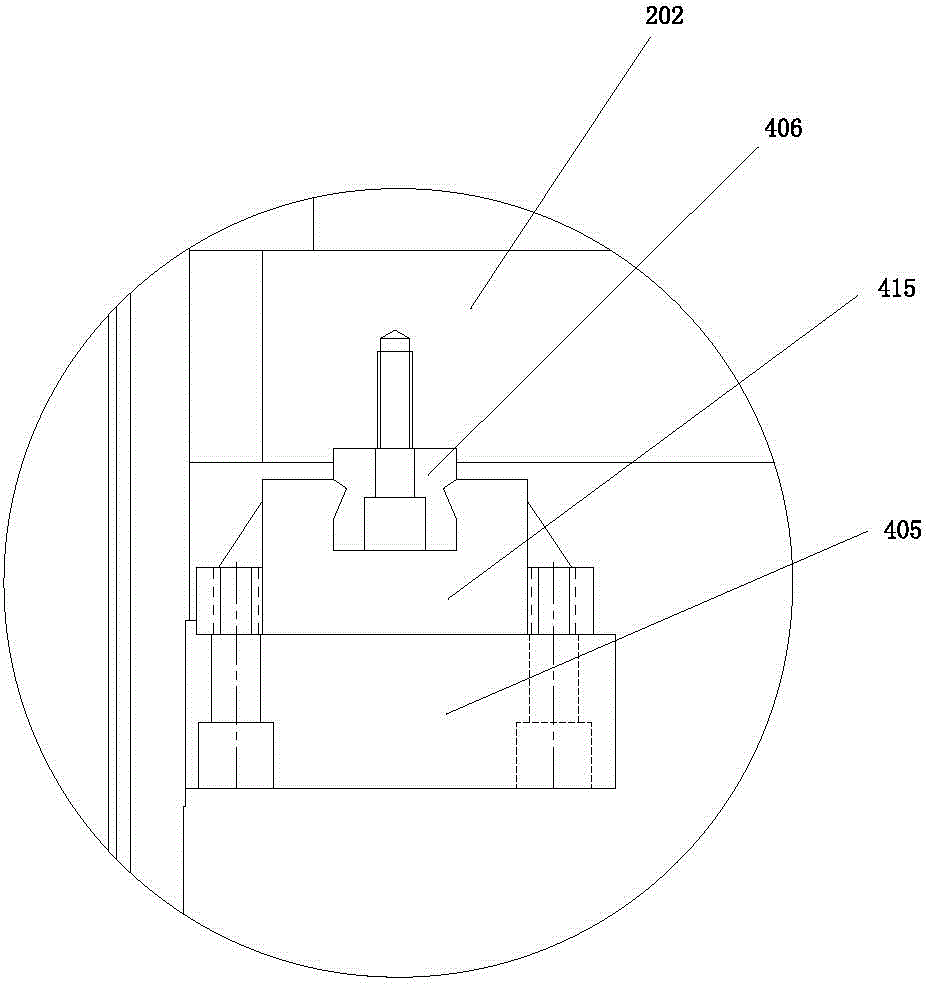

[0033] Depend on Figure 2 to Figure 9 As shown, the valve lock clip assembly assembly equipment of the present invention includes a protective assembly, an operation box assembly, a press-fit power assembly, a press-fit limit mechanism, an intake and exhaust press-fit switching servo mechanism, a press-fit chuck, and an intake and exhaust overturn mechanism. , Feeding and feeding mechanism and press-fitting support mechanism.

[0034] Depend on figure 2 As shown, the protective assembly includes a rectangular frame body 201, a first support plate 202, a second support plate 203 and a third support plate 204. The first support plate 202 is provided on the upper part of the frame body 201, and the second support plate 203 Set in the middle of the frame body 201, the third support plate 204 is set at the lower part of the frame body 201, the first support plate 202 is provided with a first through slot 205, and the second support plate 203 is provided with a second through slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com