Maintenance table device for mechanical equipment

A technology for mechanical equipment and maintenance stations, applied to workbenches, manufacturing tools, etc., can solve the problems of difficult cleaning, pollution of the working environment, waste of oil, etc., to achieve easy cleaning of oil, convenient maintenance and operation, and less oil waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

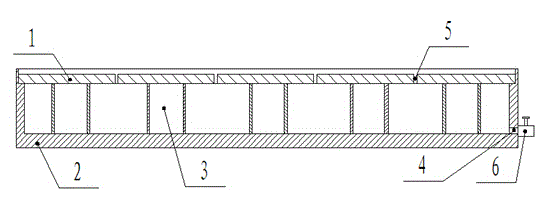

[0014] Such as Figure 1~2 As shown, the mechanical equipment maintenance platform device includes a support plate 1 and an oil tank 2. The support plate 1 is provided with multiple pieces. The support plate 1 can be a thin steel plate. There is a gap 5 between the support plate 1 and the support plate 1. The gap 5 The oil after flushing can be drained away and placed on the oil tank 2, and placed on the water tank 2 in a stacked manner, which is convenient for disassembling the support plate 1 and cleaning the accumulated residue in the water tank 2. The bottom is provided with a support placed in the oil tank 2 Column 3, the bottom of the support column 3 is fixed on the bottom of the water tank 2, arranged vertically and horizontally at intervals, which can greatly improve the supporting capacity of the support plate, the oil tank 2 is a groove structure, placed on the ground, and the upper end surface of the oil tank 2 is higher than the support for one week The upper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com