Leather strip extruder

An extruder, leather wire technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of increased transportation costs of motor vehicles, time-consuming and laborious cleaning, pollution of environmental groundwater, etc., and saves factory storage space. , The effect of improving transportation efficiency and saving transportation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

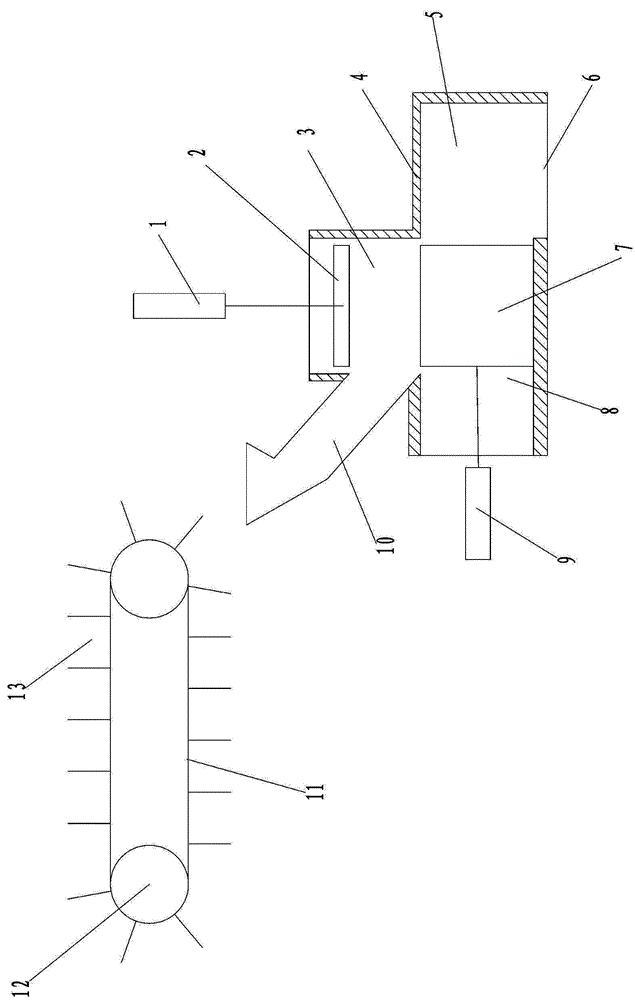

[0017] Such as figure 1 A kind of leather thread extrusion machine shown, comprises cylinder body 4, piston 2, first oil cylinder 1, forming cylinder 7, second oil cylinder 9 and feed inlet 10,

[0018] The cylinder body 4 has a rectangular cross section, and the cylinder body 4 includes a piston cavity 3, a molding cavity 8 and a feeding cavity 5,

[0019] The piston chamber 3 is located above the molding chamber 8, the feeding chamber 5 is located on the right side of the molding chamber 8, and the bottom of the feeding chamber 5 has a discharge port 6,

[0020] The top port of the forming cylinder 7 faces the piston chamber 3, the forming cylinder 7 is slidingly matched with the inner wall of the forming chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com