An adjustable crawler-type high-speed train car roof cleaning machine

A technology for high-speed trains and cleaning machines, which is applied in the direction of railway cleaning devices and vehicle exterior cleaning devices, which can solve the problems of roof cleaning of high-speed trains, dirt on the outer surface of high-speed trains, and poor mobility, and achieve strong adaptability and cleaning The effect of comprehensive effect and improvement of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

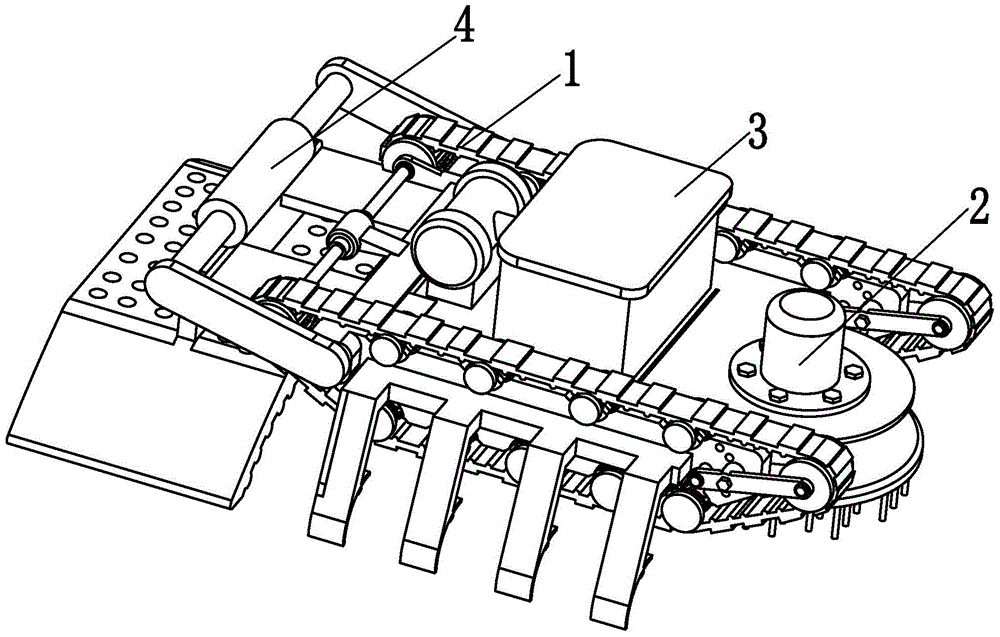

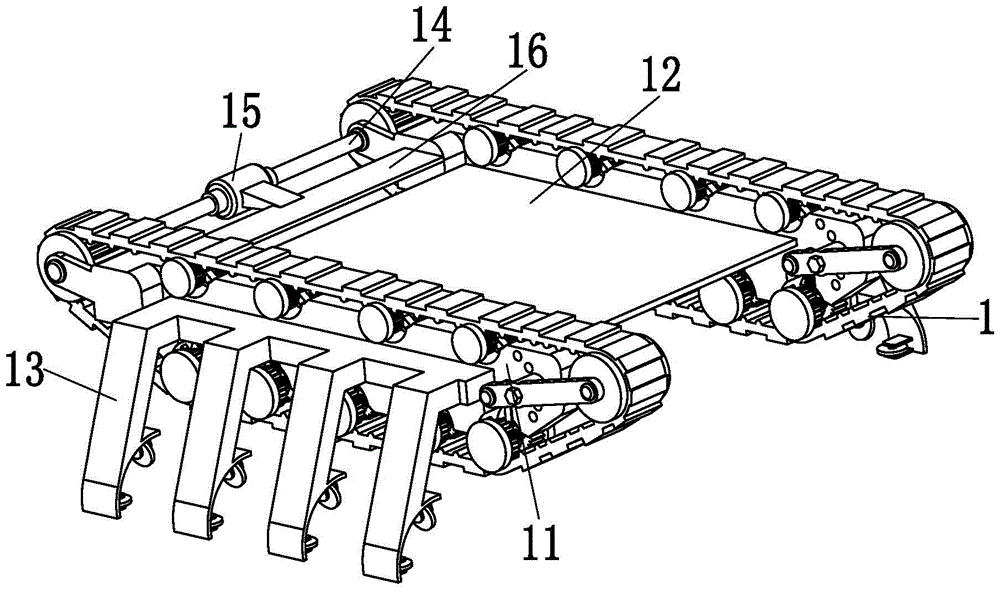

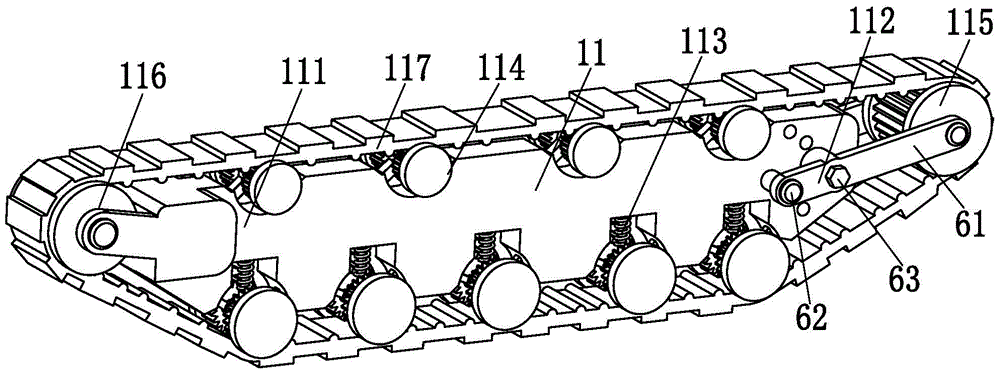

[0031] Such as figure 1 with figure 2 As shown, an adjustable crawler-type high-speed rail car roof cleaning machine includes a running device 1, a cleaning device 2, a sprinkler 3 and a drying device 4. The cleaning device 2 is located directly in front of the running device 1, and the sprinkler 3 Located in the middle of the walking device 1, the drying device 4 is located directly behind the walking device 1; the walking device 1 includes two horizontal walking bases 11, a bottom plate 12, two lateral walking bases 13, and two transmission shafts 14. The motor 15 and the base 16; the two horizontal walking bases 11 are symmetrically arranged, and the two horizontal walking bases 11 are connected through the bottom plate 12, the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com