A high yield rate candy inner box packaging equipment

A technology of box packaging and good product rate, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of not being able to produce in large quantities, assembly line production, equipment that cannot meet the requirements, and a low degree of automation. It achieves simple structure, small errors, and The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

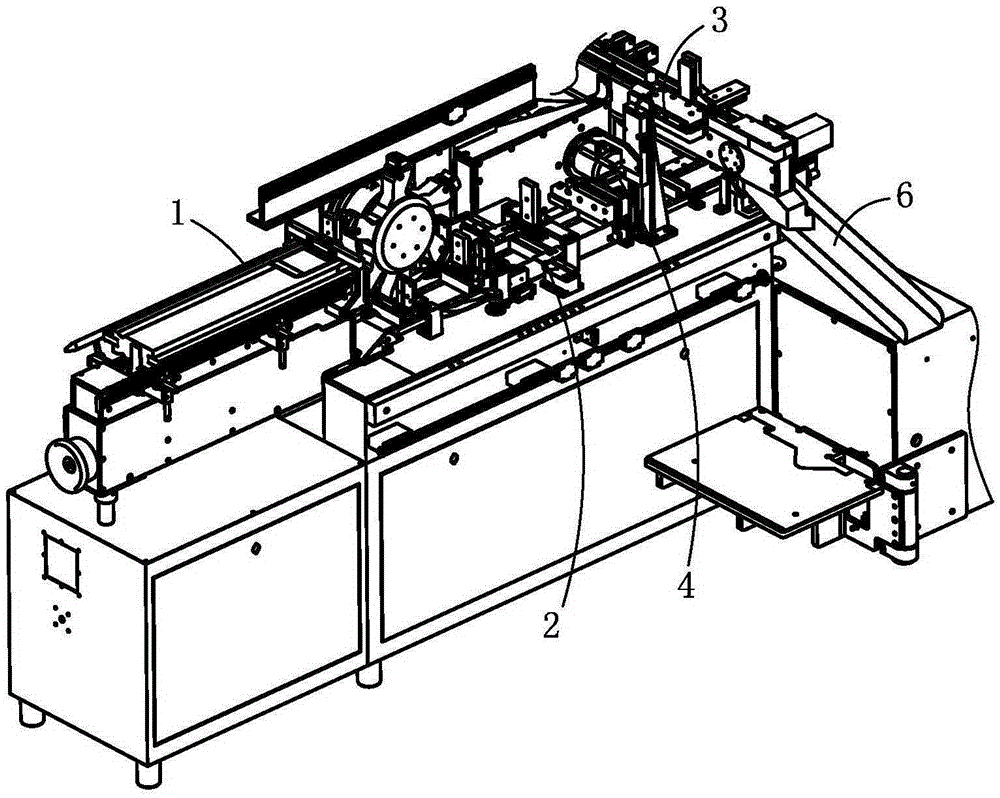

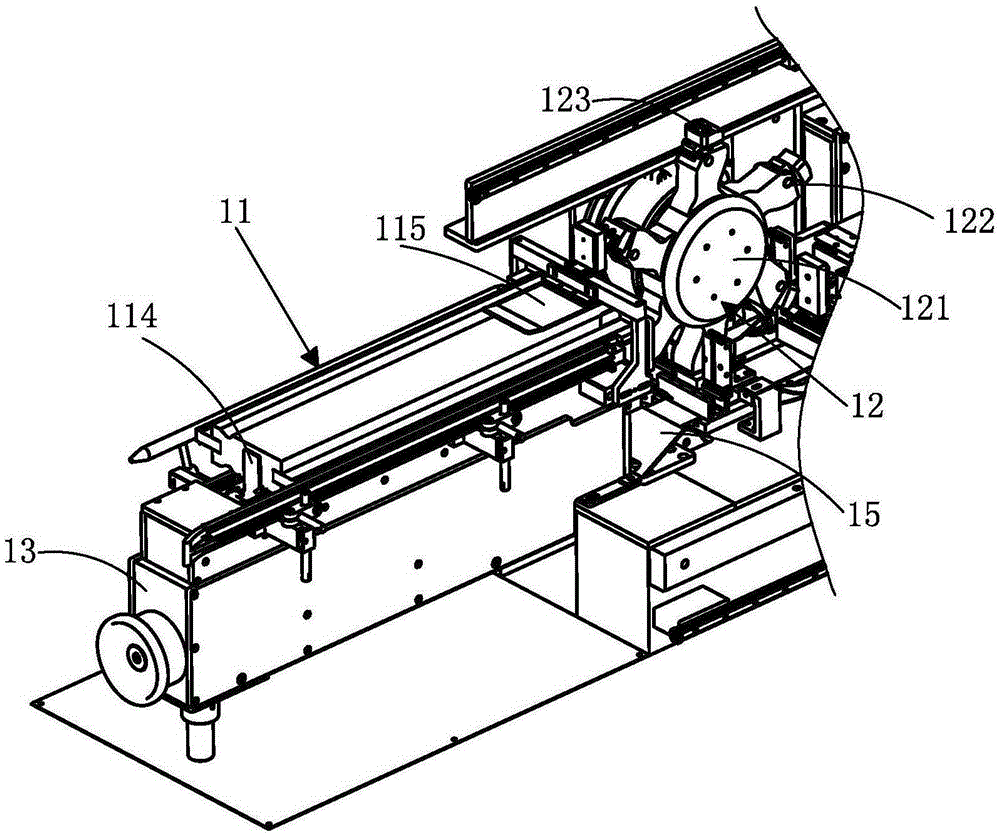

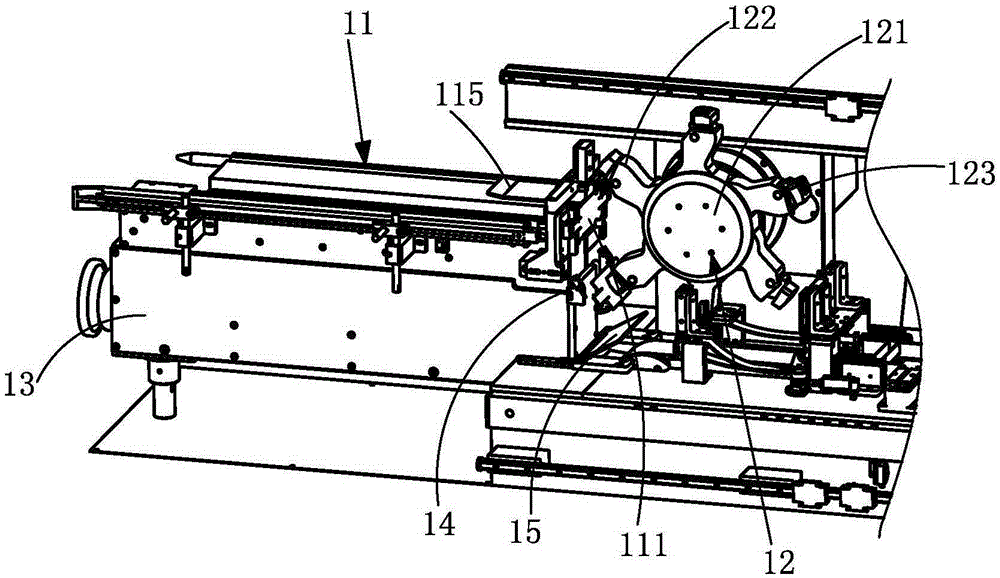

[0026] Such as Figure 1-12 As shown, the present invention needs to fold the cut inner box cardboard into a candy packaging inner box, and complete the packaging of the candy inner box at the same time. The whole operation has gone through the process of feeding the inner box, forming the inner box, transferring the candy and combining the candy with the inner box.

[0027] Such as Figure 1-11 As shown, the present invention discloses a candy inner box packaging equipment with a high yield rate, which includes an inner box paper feeding device 1, an inner box forming device 2, and a candy transfer device 3. The inner box paper feeding device 1 is installed in the inner box forming device to feed The paper end 25 and the candy transfer device 3 are installed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com