Tackiness agent storage tank

An adhesive and storage tank technology, applied in the field of adhesive storage tanks, can solve the problems of low efficiency, time-consuming and labor-intensive, etc., and achieve the effect of improving the efficiency of equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

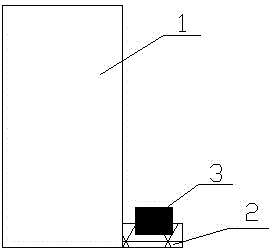

[0009] Such as figure 1 It is a structural schematic diagram of the present invention, an adhesive storage tank, including a storage tank main body 1, a glue outlet 2 is provided at the lower right end of the storage tank main body 1, and a liquid flow controller 3 is provided at the glue outlet 2. During use, the liquid flow controller 3 can control the discharge of the glue solution, and simultaneously display the discharge amount of the glue solution, and then weigh after the glue is discharged.

[0010] The improved adhesive storage tank realizes real-time monitoring of glue liquid, precisely controls the amount of liquid, avoids the trouble of secondary weighing, and improves the efficiency of equipment use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com