An anti-dust dumping device

It is a technology for turning the box and pouring materials and preventing dust. It is applied in the directions of packaging, loading/unloading, transportation and packaging. It can solve the problems of polluting the surrounding environment, large dust, and waste of tobacco, so as to reduce environmental pollution, prevent dust, and eliminate The effect of wasted tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

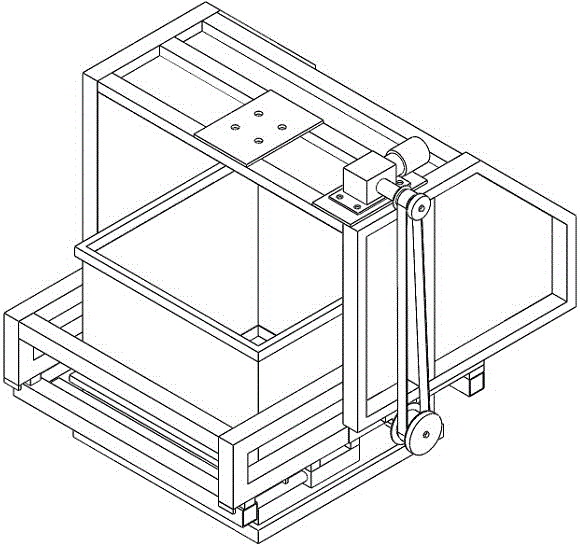

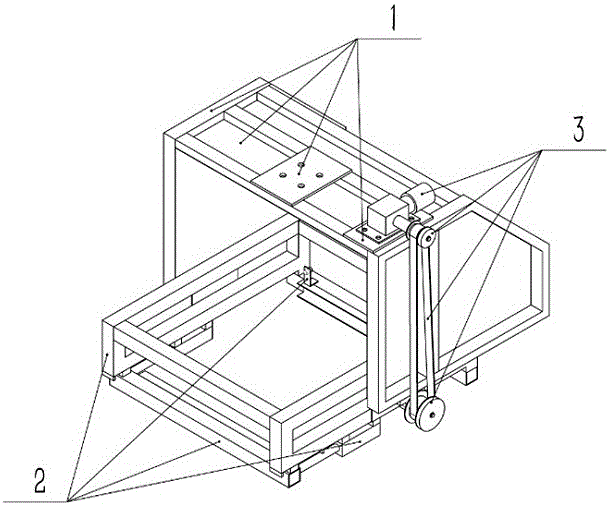

[0020] Embodiment 1: Reference figure 1 , 2 , 3. An anti-dust turning and dumping device, comprising a fixed outer frame 1, a movable inner frame 2, and a turning drive part 3, and the fixed outer frame 1 and the movable inner frame 2 are connected by bearings with seats 1-5; The skin 1-2 on the fixed outer frame 1 and the side plate of the feeding bin form a semi-enclosed space, and the movable inner frame 2 sinks into the inside of the feeding bin, and the turning over of the box is realized by the driving part 3 .

Embodiment 2

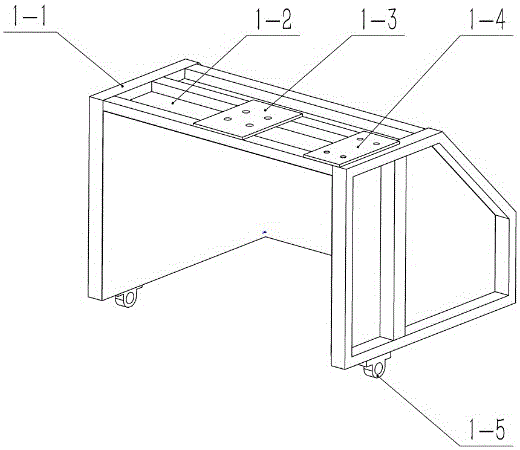

[0021] Embodiment two: reference image 3 , 4 , 5, 6, the fixed outer frame 1 is composed of an outer frame body 1-1, a skin 1-2, a first connecting plate 1-3, a second connecting plate 1-4 and a bearing with seat 1-5; The outer frame body 1-1 is welded by the left and right trapezoidal frames, three beams on the top, and two beams on the side; the skin 1-2 is covered inside the outer frame body 1-1; the first connecting plate 1-3 is welded on the outer frame body 1-1 top middle position, the first connecting plate 1-3 is connected to the robot through bolts; the second connecting plate 1-4 is welded on the right side of the top of the outer frame body 1-1, and the second connecting plate 1-4 is connected to the motor through bolts 3-1 connection; the bearing with seat 1-5 is fixed under the outer frame body 1-1 by bolts.

[0022] The movable inner frame 2 is composed of an inner frame body 2-1, a C-shaped handle 2-2, a metal sensor 2-3, and a cylinder pulling assembly 2-4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com