Pressure adjusting mechanism for rope pressing mechanism of elevator

A pressure rope mechanism and pressure adjustment technology, applied in elevators, transportation and packaging, etc., can solve the problems of difficult adjustment, time-consuming, laborious assembly and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

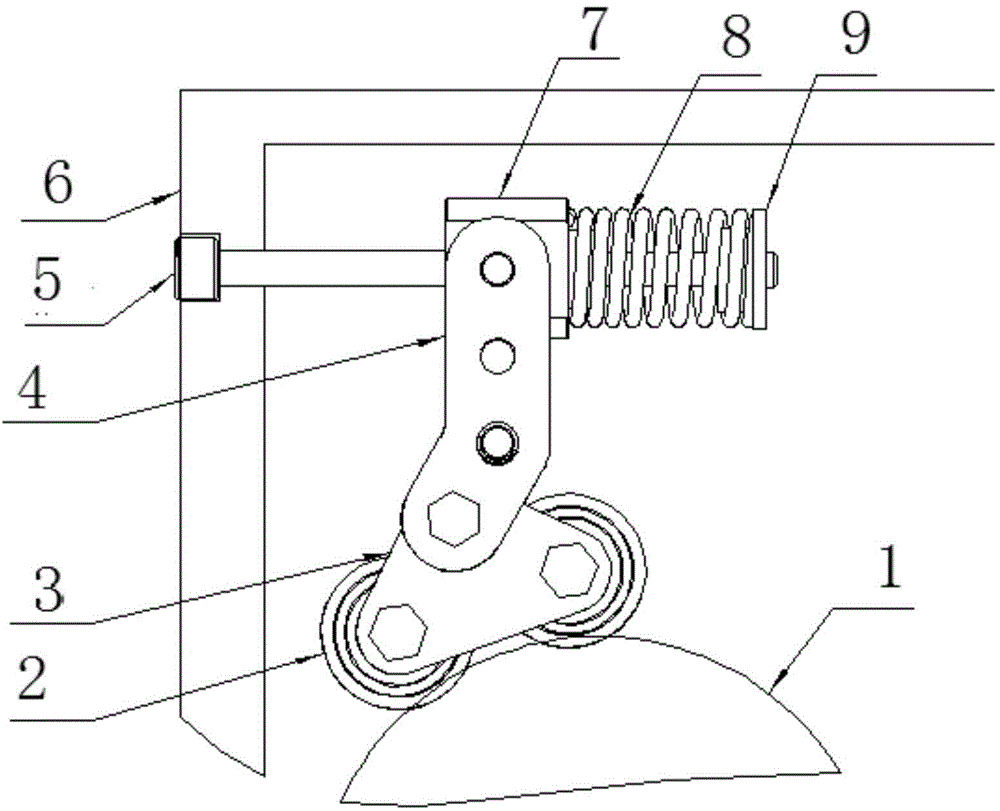

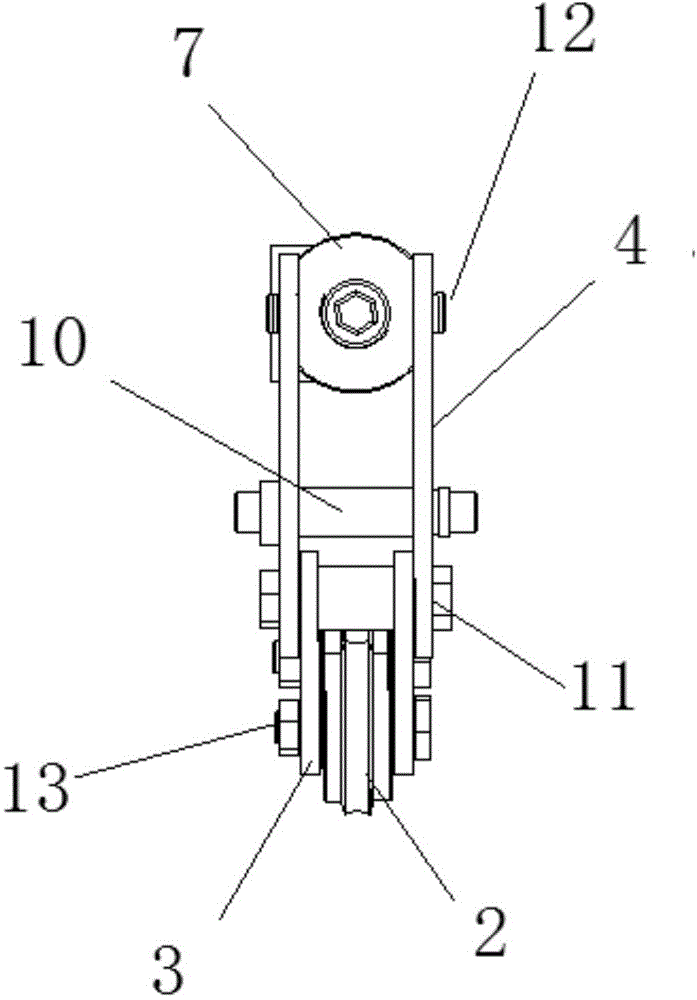

[0015] see Figure 1~2 , a pressure regulating device for a rope-pressing mechanism of a hoist, comprising a rope-pressing mechanism cooperating with a rope-traveling wheel 1, the rope-pressing mechanism comprising two rope-pressing wheels 2; the two rope-pressing wheels are connected through a connecting plate 3 Lever arm 4, described lever arm 4 connects pressure adjustment mechanism, and described pressure adjustment mechanism comprises adjusting lever 5 and spring mechanism, and described spring mechanism comprises spring 8 and spring holder 7, spring pressing plate 9, and described spring holder 7 connects all Described lever arm 4, described adjusting rod 5 is threadedly connected with described spring pressing plate after passing through described spring bracket, spring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com