Liquid filling machine

A filling machine and liquid technology, applied in liquid bottling, liquid treatment, packaging, etc., can solve the problems of filling conveyor belt pollution, filling bottle pollution, inaccurate measurement, etc., to avoid pollution, clean the whole, and reduce waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

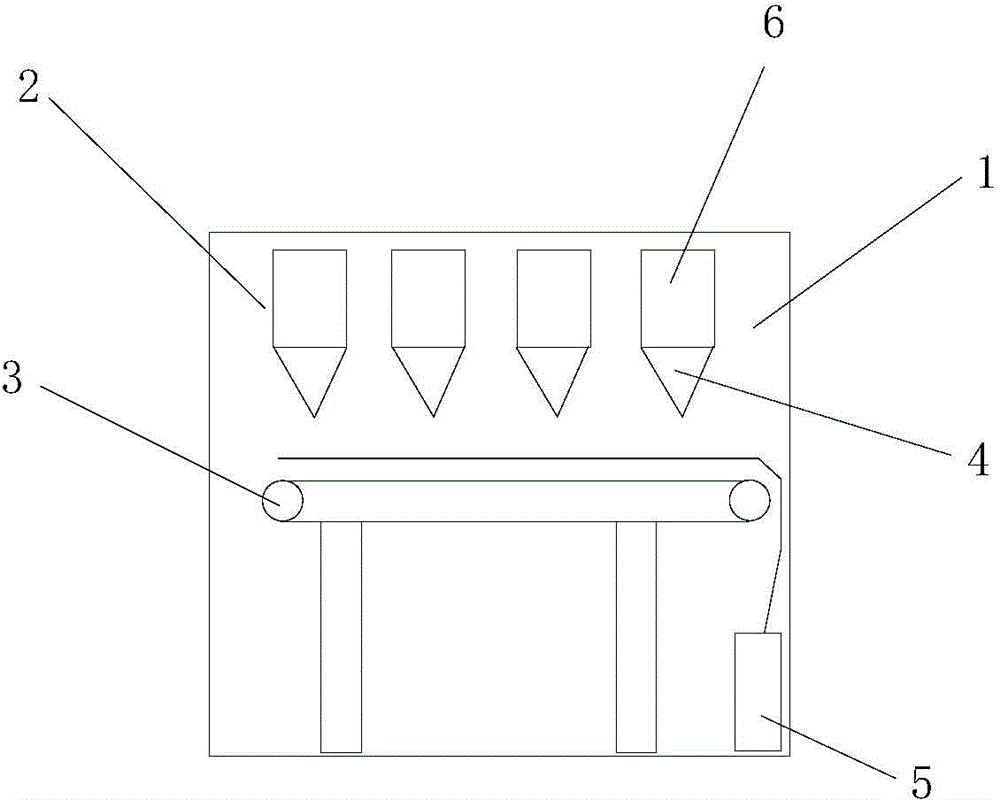

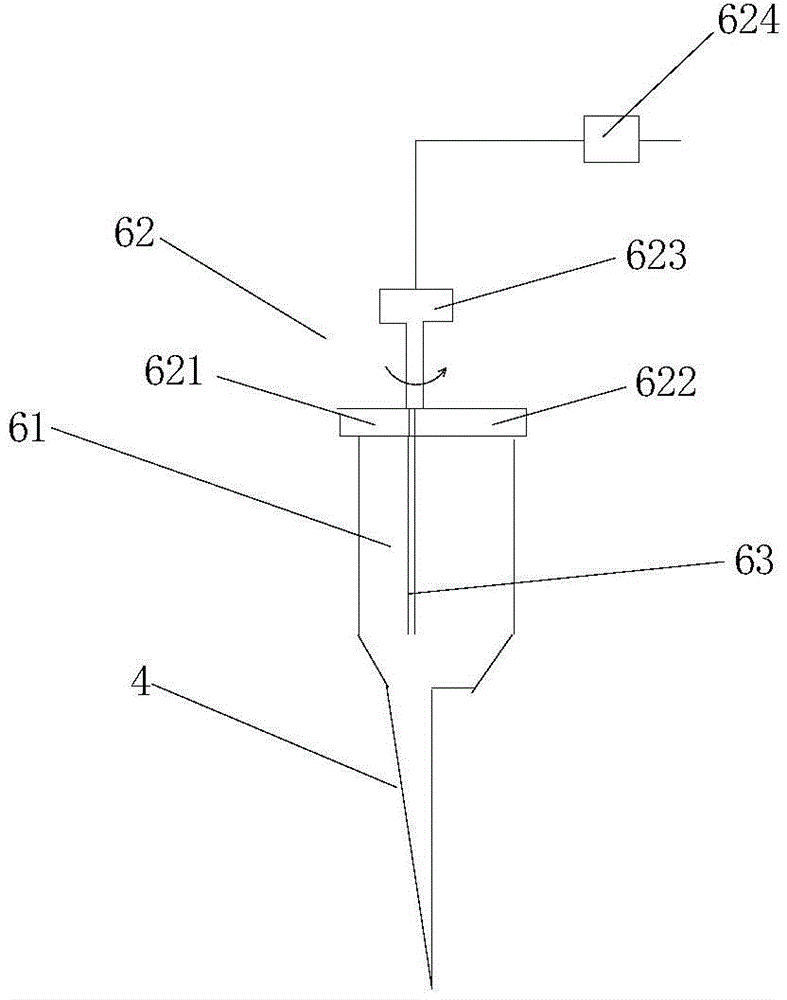

[0013] Such as figure 1 The shown liquid filling machine includes a transparent and closed filling chamber 1, the filling chamber 1 is provided with a liquid filling machine 2, and the liquid filling machine 2 includes a filling transmission belt 3, in Above the filling conveyor belt 3, there are a plurality of filling nozzles 4 arranged in a line, and directly below the filling nozzles 4 and directly above the filling conveyor belt 3, there is a Drip liquid recovery device 5, the filling nozzle 4 is connected to the filling valve 6, the inside of the filling valve 6 is provided with two channels 61 of different sizes, and the upper part of the filling valve 6 is provided with Large and small channel switching device 62.

[0014] The switching device 62 includes a first blocking piece 621 and a second blocking piece 622 , the first blocking piece 621 and the second blocking piece 622 are connected to a pillar 623 , and the pillar 623 is connected to a controller 624 .

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com