Batch method for rapid preparation of high-density carbon/carbon composites

A carbon composite material and high-density technology, which is applied in the field of rapid preparation of high-density carbon/carbon composite materials in batches, can solve the problems of not being able to achieve rapid densification, mass production, and difficult industrial production, and achieve intelligent process operation control The effects of chemicalization, short preparation cycle and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

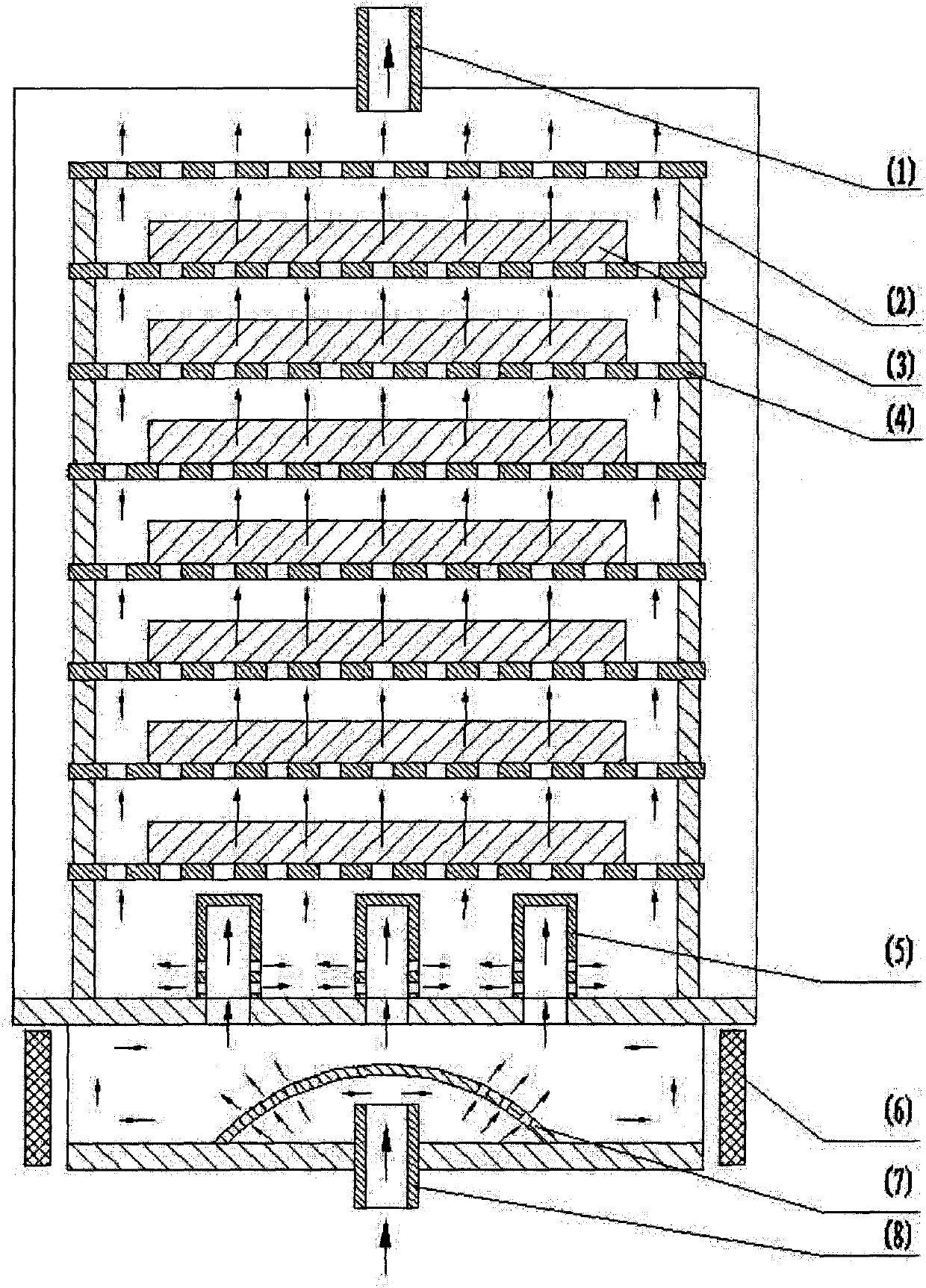

[0022] An intermediate frequency power supply chemical vapor deposition furnace is used (the diameter of the furnace cavity is 650MM and the height is 1600MM). The size of 12 preforms is 4001mm×400mm×30mm. The outer diameter of 12 graphite ring pads is 600mm and the height is 80mm. 12 pieces of porous The outer diameter of the graphite disc is 600 mm, the thickness is 30 mm, and 100 through holes with a diameter of 15 mm are evenly distributed on the disc. The steps are as follows:

[0023] (1) Put the prefabricated body and fixtures into the deposition furnace, close the furnace cover, evacuate the furnace to a pressure of <10Pa, start the heating program, and raise the temperature to 800-1100°C; open the gas valve, and let natural gas and nitrogen pass through After the gas tank is mixed evenly, it enters the deposition furnace.

[0024] (2) Enter the temperature control program, gas flow control program and air pressure control program for staged operation: the preheating ...

example 2

[0027] The chemical vapor deposition furnace with intermediate frequency power supply is used (the diameter of the furnace chamber is 650MM, and the height is 1600MM). The size of 12 preforms is 400mm×400mm×20mm, and the outer diameter of 12 graphite ring pads is 600mm. The height is 80mm, and 12 pieces are porous The outer diameter of the graphite disc is 600 mm, the thickness is 30 mm, and 100 through holes with a diameter of 15 mm are evenly distributed on the disc. The steps are as follows:

[0028] (1) Put the prefabricated body and fixtures into the deposition furnace, close the furnace cover, evacuate the furnace to a pressure of <10Pa, start the heating program, and raise the temperature to 800-1100°C; open the gas valve, and let natural gas and nitrogen pass through After the gas tank is mixed evenly, it enters the deposition furnace.

[0029] (2) Enter the temperature control program, gas flow control program and air pressure control program for staged operation: th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com