Convenient steam explosion device for blasting dried eucommia bark

The technology of a steam explosion device and Eucommia bark is applied in the field of convenient steam explosion devices, which can solve the problems of cumbersome operation, heavy workload, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

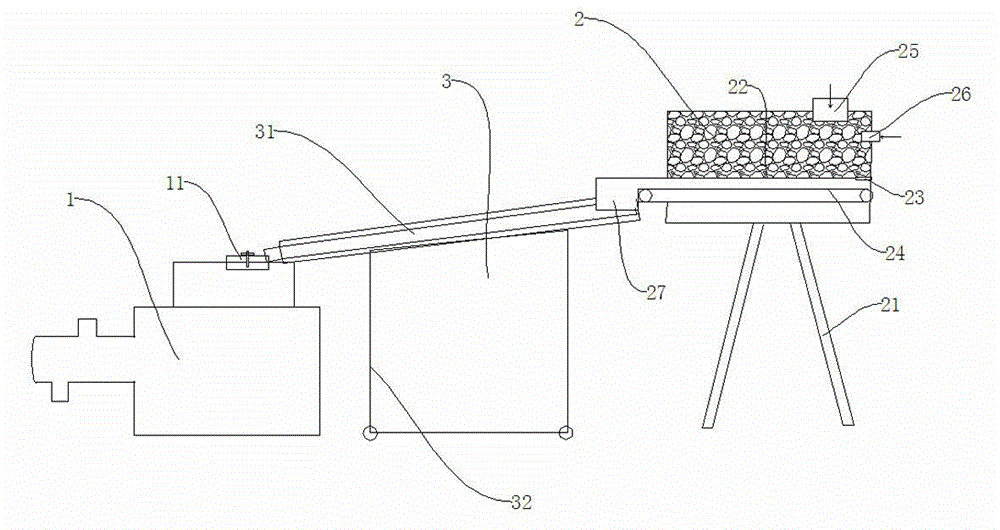

[0024] like figure 1 Shown, a kind of convenient type steam explosion device that is used for dry ulmoides bark blasting comprises steam explosion tank 1, and the top of steam explosion tank is provided with feed port 11; Described steam explosion device also includes soaking box 2 and transfer table 3; a fixed frame 21 is provided below the soaking box, and a partition 22 is arranged inside the soaking box to divide the interior into upper and lower spaces, and an opening and closing port 23 is provided on the partition; a transmission belt 24 is provided below the partition, There is a material transfer space between the partition and the transmission belt; the soaking tank is also provided with a feeding port 25 and a water inlet 26 at the part above the partition, and a discharge pipe 27 is provided at the part below the partition, and the discharge pipe 27 Be positioned at the end of transmission belt transmission direction; Described transmission platform 3 is made up of...

Embodiment 2

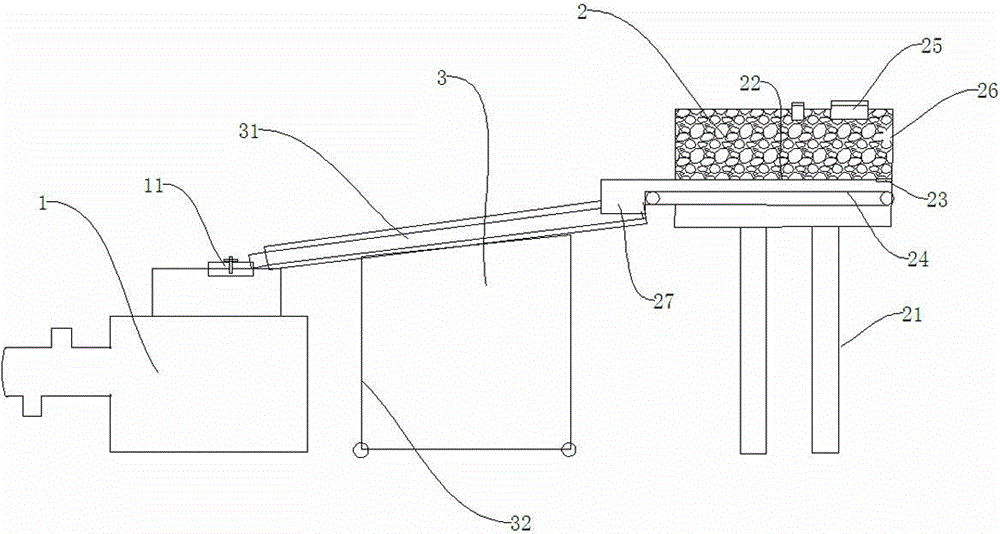

[0032] like figure 2 Shown, a kind of convenient type steam explosion device that is used for dry ulmoides bark blasting comprises steam explosion tank 1, and the top of steam explosion tank is provided with feed port 11; Described steam explosion device also includes soaking box 2 and transfer table 3; a fixed frame 21 is provided below the soaking box, and a partition 22 is arranged inside the soaking box to divide the interior into upper and lower spaces, and an opening and closing port 23 is provided on the partition; a transmission belt 24 is provided below the partition, There is a material transfer space between the partition and the transmission belt; the soaking tank is also provided with a feeding port 25 and a water inlet 26 at the part above the partition, and a discharge pipe 27 is provided at the part below the partition, and the discharge pipe 27 Be positioned at the end of transmission belt transmission direction; Described transmission platform 3 is made up o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com