Oil pipe anti-overflow tool for direct flushing and indirect flushing

A well tubing, forward and backwashing technology, which is applied in the direction of flushing the wellbore, wellbore/well components, earthwork drilling and production, etc., can solve the problems of personal injury at the gate, difficult recovery, and inability to cut off the cable, etc., to extend the full flow of the tubing The time, the effect of speeding up the work progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

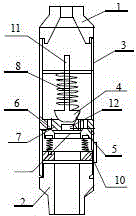

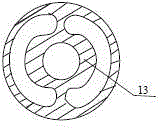

[0017] like figure 1 Shown: a positive and reverse oil tubing overflow prevention tool, including an upper joint 1, a lower joint 2 and an anti-overflow body 3, the upper joint 1 is connected with a centralizing rod 11, and the centralizing rod 11 is connected with a reverse valve 4. The reverse valve 4 is connected with a reverse valve seat 5, the length of the centralizing rod 11 is 15-35cm, the centralizing rod 11 is provided with a valve spring 8, and the valve spring 8 is connected to The reverse valve seat 4 is connected, one end of the reverse valve seat 5 is connected with a forward spline type circumferential through hole 6, and the other end of the reverse valve seat 5 is connected with a reverse valve hole 12 , the anti-overflow body 3 is provided with a normally open through hole 7, the lower end of the anti-overflow body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com