A kind of production method of sinking roller

A production method and technology of sinking rolls, which are applied in the manufacture of tools, coatings, turning equipment, etc., can solve problems such as scratches, slippage between sinking rolls and steel plates, and lower steel plate quality, so as to prolong the time of stacking and uniform coating thickness , The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments. and features in the embodiments may be combined with each other.

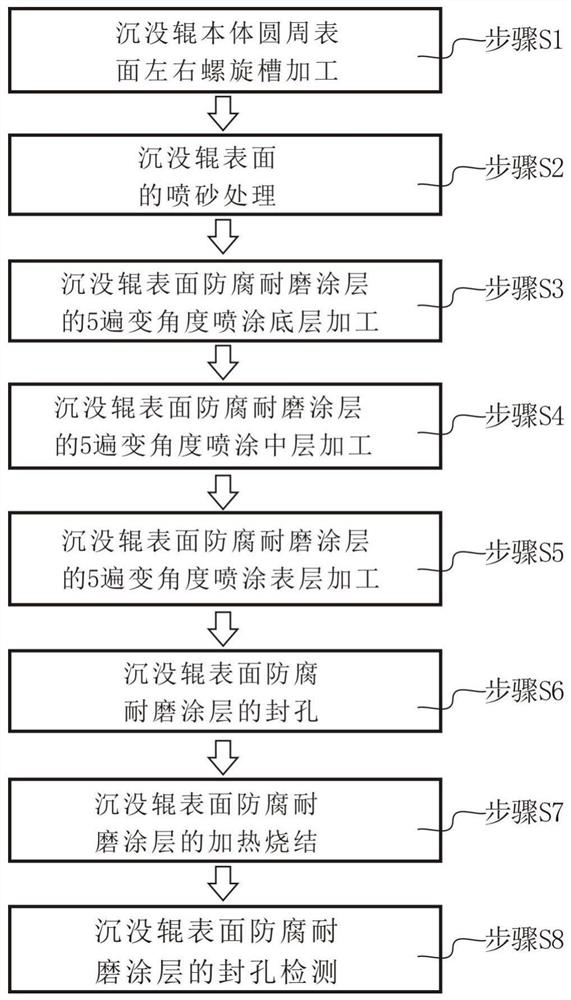

[0041] like figure 1 As shown, a production method of a sunken roll includes the following steps:

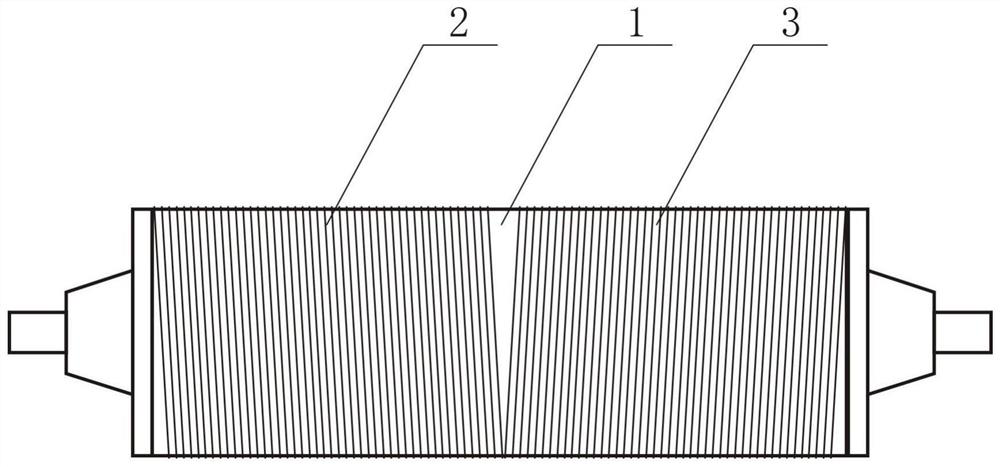

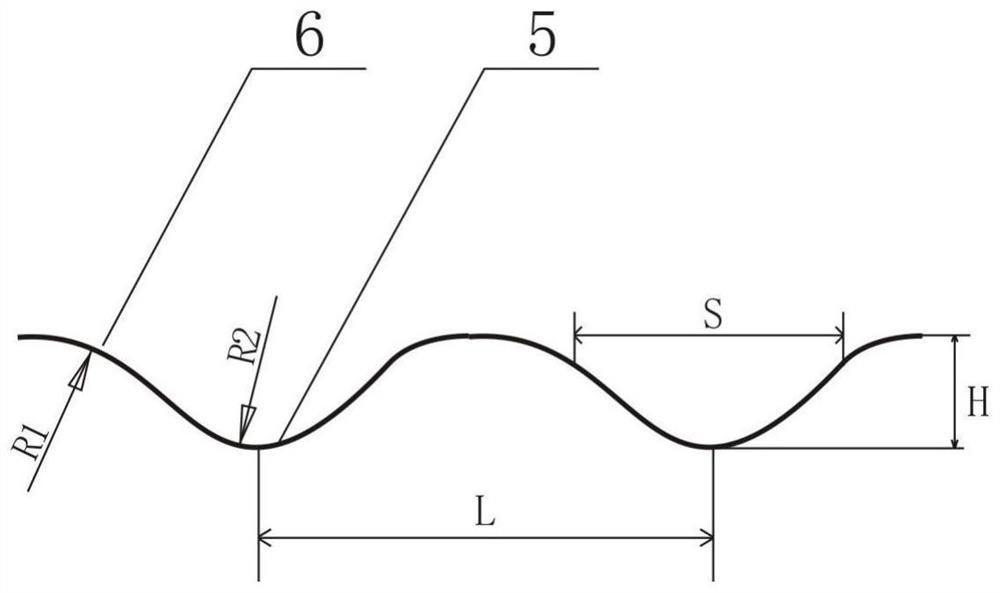

[0042] Step S1, machining the left and right spiral grooves on the circumferential surface of the submerged roller body: clamp the submerged roller body 1 on a lathe, the lathe drives the submerged roller body to rotate, and the turning tool moves from one end of the submerged roller body along the axis of the submerged roller body, The turning tool performs helical groove machining on the circumferential surface of the submerged roller body 1. When the turning tool moves to the middle of the submerged roller body, the turning tool stops moving and the submerged rol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com